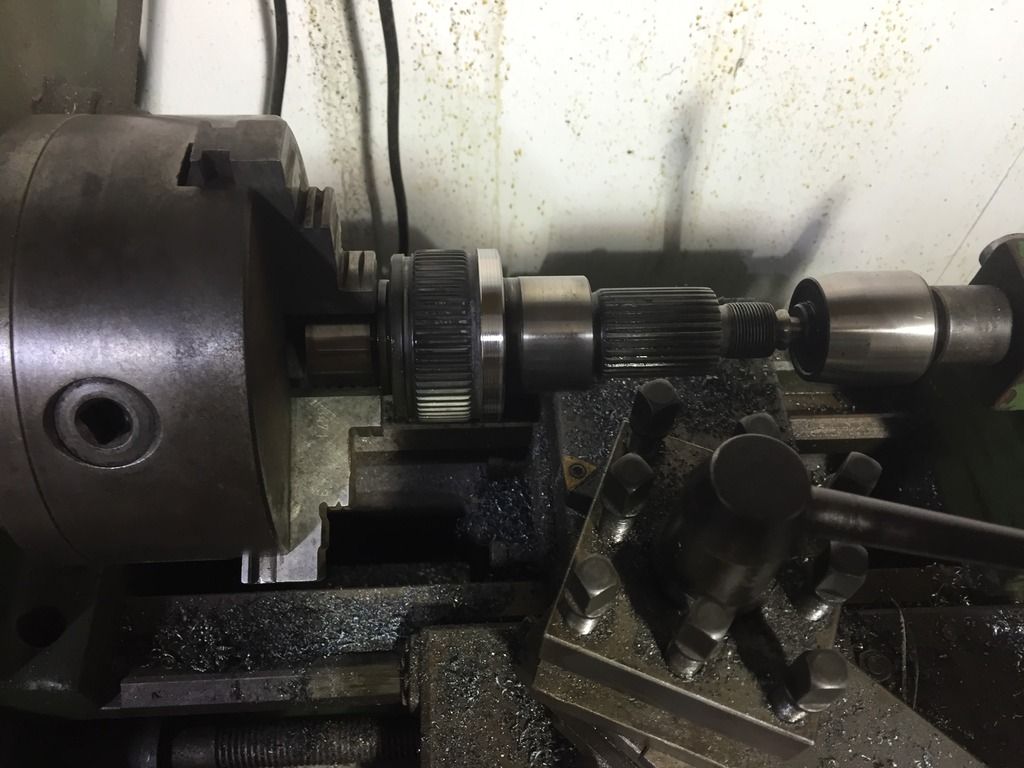

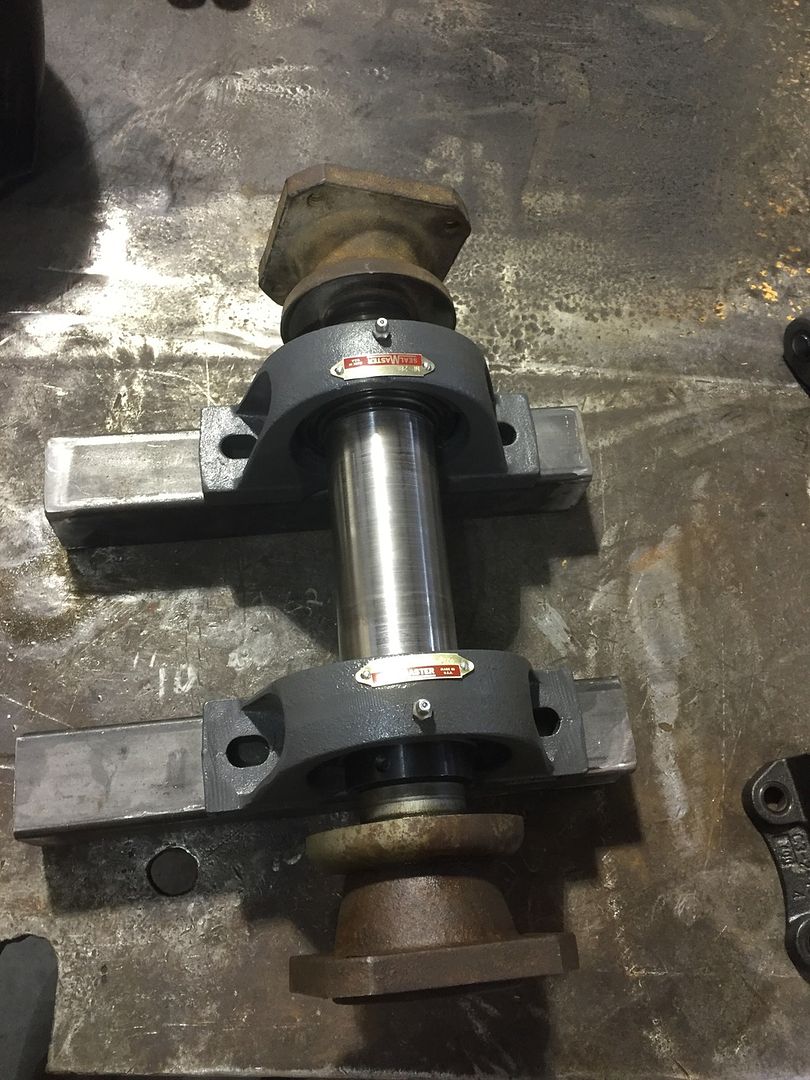

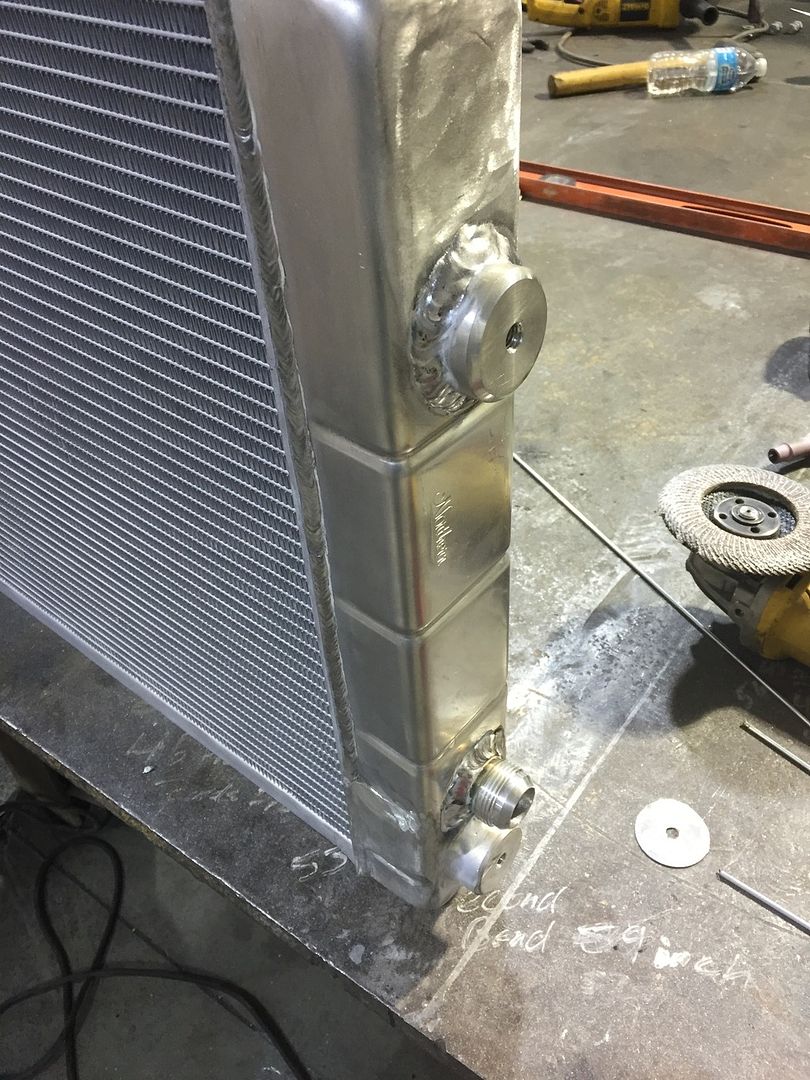

Figured I would start a build thread for this buggy I started a while back. I did some trading and ended up with a set of steering rockwells so I figured that would be a good place to start building around. So I got a 6.0 and a 4l80e and a 3.0 atlas and got it all put on the table ready to start bending tube....... Then my wife decided to have our first child a sweet baby girl so that kinda slows progress but this is what I have got done in the past few months any advice please feel free to share shooting for 20 inch belly with 10 inch of up travel at ride height