DirtMonkey

Well-Known Member

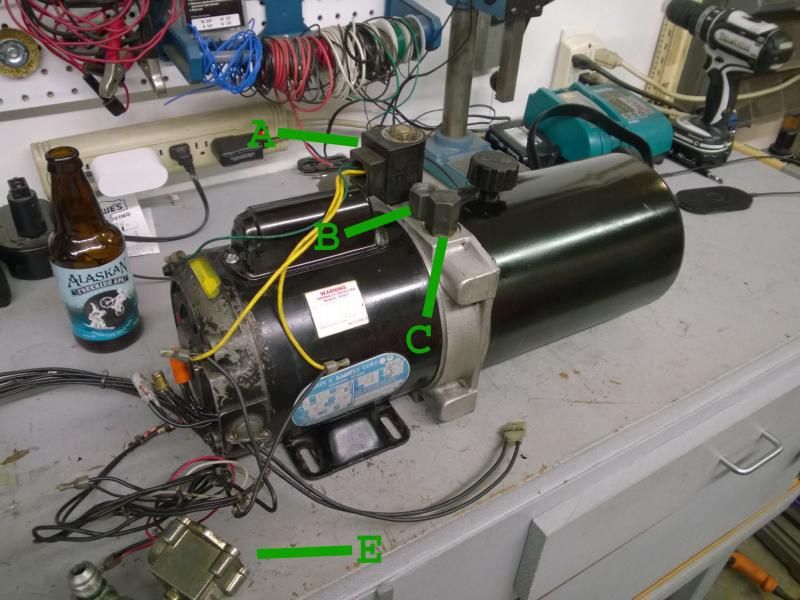

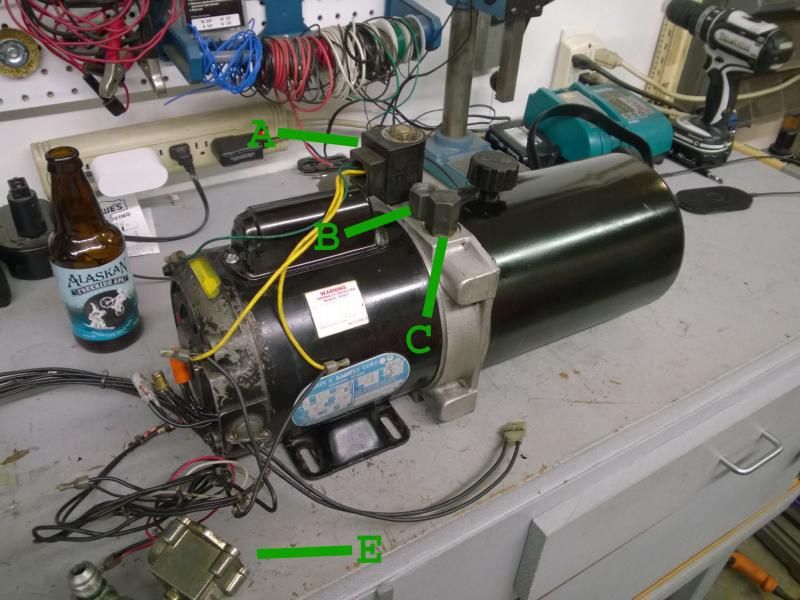

Ok, I have this hydraulic power unit...its a used Barnes model. I want to go elec/hydro on my bender. Rigging the bender mod is straight forward, but I'm not sure I picked up the right power unit. I have no idea what application this one was used on prior, but if I understand this right, the unit drives a cylinder until desired end point then the solenoid "A" is energized allowing flow which would allow the cylinder to gravity descend. Correct? I'm thinking this was used on a lift gate or something similar, where the work weight lowered the cylinder.

Being that I want to drive a double action cylinder with a 4 way valve like this http://www.northerntool.com/shop/tools/product_472_472?cm_mmc=Google-pla-_-Hydraulics-_-Hydraulic%20Valves-_-2020&ci_src=17588969&ci_sku=2020&ci_src=17588969&ci_sku=2020&gclid=Cj0KEQiAuMOlBRDf6_izz93n-pEBEiQAsJCJWmfxkY7ZcLuqYsnomNx_N5wu6uzGI4Ez3OnFaIQej3QaAmx28P8HAQ Could I just wire "A" to be open all the time and use the 4 way to drive the fluid? I've seen the power units with just a return and pressure outputs and no solenoid. Is that what I have to get or can this unit work?

Any info is appreciated

Being that I want to drive a double action cylinder with a 4 way valve like this http://www.northerntool.com/shop/tools/product_472_472?cm_mmc=Google-pla-_-Hydraulics-_-Hydraulic%20Valves-_-2020&ci_src=17588969&ci_sku=2020&ci_src=17588969&ci_sku=2020&gclid=Cj0KEQiAuMOlBRDf6_izz93n-pEBEiQAsJCJWmfxkY7ZcLuqYsnomNx_N5wu6uzGI4Ez3OnFaIQej3QaAmx28P8HAQ Could I just wire "A" to be open all the time and use the 4 way to drive the fluid? I've seen the power units with just a return and pressure outputs and no solenoid. Is that what I have to get or can this unit work?

Any info is appreciated