-

Help Support Hardline Crawlers :

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tech: At wits end with an overheating motor, long post

- Thread starter customcj7

- Start date

customcj7

Well-Known Member

Alright, so here's where I'm at with the engine.

-Replaced the water pump, and then kept the radiator filled with water, but not with direct pressure from the hose. Flow was constant and in my opinion, like it should be, especially at idle.

- Ran it for a while, took it about 5 miles down the road and back, let it sit in it's own heat after a hot shutdown, etc. Gauge reached nearly 250 degrees, but no steam. Everything ran fine.

- Picked up an IR thermometer to do temp readings, as best as I can tell it's fairly accurate +/- 10 degrees. Did various heat checks on parts of the engine. Temp gauge read almost 250, water temp in the radiator top was around 210. Intake was 205, with various other locations in the 200 degree range.

- Here's where it got weird, almost every exhaust header port was around 325-350, except number 6 and number 7 cylinder were 480-495 degrees. That big of a swing would typically mean something to me.

Now, backtrack. When I did my tune up on my engine, everything ran fine. Cooling was decent, engine ran well enough, some carb adjustments needed to be dialed in as it was very rich, but it ran well. All this work was because a loose wire dropped onto the headers and cooked and fried the electrical system. I couldn't trace the problem in my spiderweb **** show of wiring, so I took it as a sign to finally fix the hack job of wiring I had. Doing so, I opted to tune up the motor. I changed out the points ignition system for a Petronix Ignitor III system with Petronix coil. New cap, rotor, plugs, and wires. IMPORTANT: The distributor stayed the same, never moved it, loosened it, changed it, etc. Now when I go to fire it up the first time, to say it ran rough was an understatement, it could barely run at all. Headers got stupid red hot in seconds. Timing was WAY off. So I put a timing gun on it, and dialed it in and it smoothed out right there. Seemingly all is right with the world.

However, I think I may still have some timing issue. I did it before, but I think I missed something when I checked TDC on the block when I verified my timing marks to be accurate. So I'm going to pull #1, verify TDC and the distributor are lined up like they should be. My engine is supposed to be at 10 degrees BTDC, so I'll verify that next.

Again, the engine ran smooth, hell it ran smoother before I started messing with the carb again, now it's flooding like mad again.

But here is the odd question Why would the tune up cause it to get so far out of timing when the distributor wasn't even touched? I mean it took a quarter turn of the distributor to get it back into correct timing, close to 30 degrees off.

SIDENOTE: I'm also going to pick up a mechanical temp gauge to verify my electrical gauge is right based on those IR thermometer readings.

-Replaced the water pump, and then kept the radiator filled with water, but not with direct pressure from the hose. Flow was constant and in my opinion, like it should be, especially at idle.

- Ran it for a while, took it about 5 miles down the road and back, let it sit in it's own heat after a hot shutdown, etc. Gauge reached nearly 250 degrees, but no steam. Everything ran fine.

- Picked up an IR thermometer to do temp readings, as best as I can tell it's fairly accurate +/- 10 degrees. Did various heat checks on parts of the engine. Temp gauge read almost 250, water temp in the radiator top was around 210. Intake was 205, with various other locations in the 200 degree range.

- Here's where it got weird, almost every exhaust header port was around 325-350, except number 6 and number 7 cylinder were 480-495 degrees. That big of a swing would typically mean something to me.

Now, backtrack. When I did my tune up on my engine, everything ran fine. Cooling was decent, engine ran well enough, some carb adjustments needed to be dialed in as it was very rich, but it ran well. All this work was because a loose wire dropped onto the headers and cooked and fried the electrical system. I couldn't trace the problem in my spiderweb **** show of wiring, so I took it as a sign to finally fix the hack job of wiring I had. Doing so, I opted to tune up the motor. I changed out the points ignition system for a Petronix Ignitor III system with Petronix coil. New cap, rotor, plugs, and wires. IMPORTANT: The distributor stayed the same, never moved it, loosened it, changed it, etc. Now when I go to fire it up the first time, to say it ran rough was an understatement, it could barely run at all. Headers got stupid red hot in seconds. Timing was WAY off. So I put a timing gun on it, and dialed it in and it smoothed out right there. Seemingly all is right with the world.

However, I think I may still have some timing issue. I did it before, but I think I missed something when I checked TDC on the block when I verified my timing marks to be accurate. So I'm going to pull #1, verify TDC and the distributor are lined up like they should be. My engine is supposed to be at 10 degrees BTDC, so I'll verify that next.

Again, the engine ran smooth, hell it ran smoother before I started messing with the carb again, now it's flooding like mad again.

But here is the odd question Why would the tune up cause it to get so far out of timing when the distributor wasn't even touched? I mean it took a quarter turn of the distributor to get it back into correct timing, close to 30 degrees off.

SIDENOTE: I'm also going to pick up a mechanical temp gauge to verify my electrical gauge is right based on those IR thermometer readings.

blacksheep10

XBJRA champ/ 555 and team Nasty codriver

#1 moved one (or 2) positions. 360/8 is 45, or it moved 2 positions if you turned it 90 deg (1/4 turn). You could have moved your wires back to where they were. I know you are going to say you put 1 back where it was, does the rotor clock on there different to a key? Does the cap go on different? If the rotor points the same as it did before and the cap orients the same, and the wires went back in the exact same place, I call BS that it was 1/4 turn off. I'd say your wires were 1/8 off meaning one position off.

TBItoy

Well-Known Member

Just because I've done it before

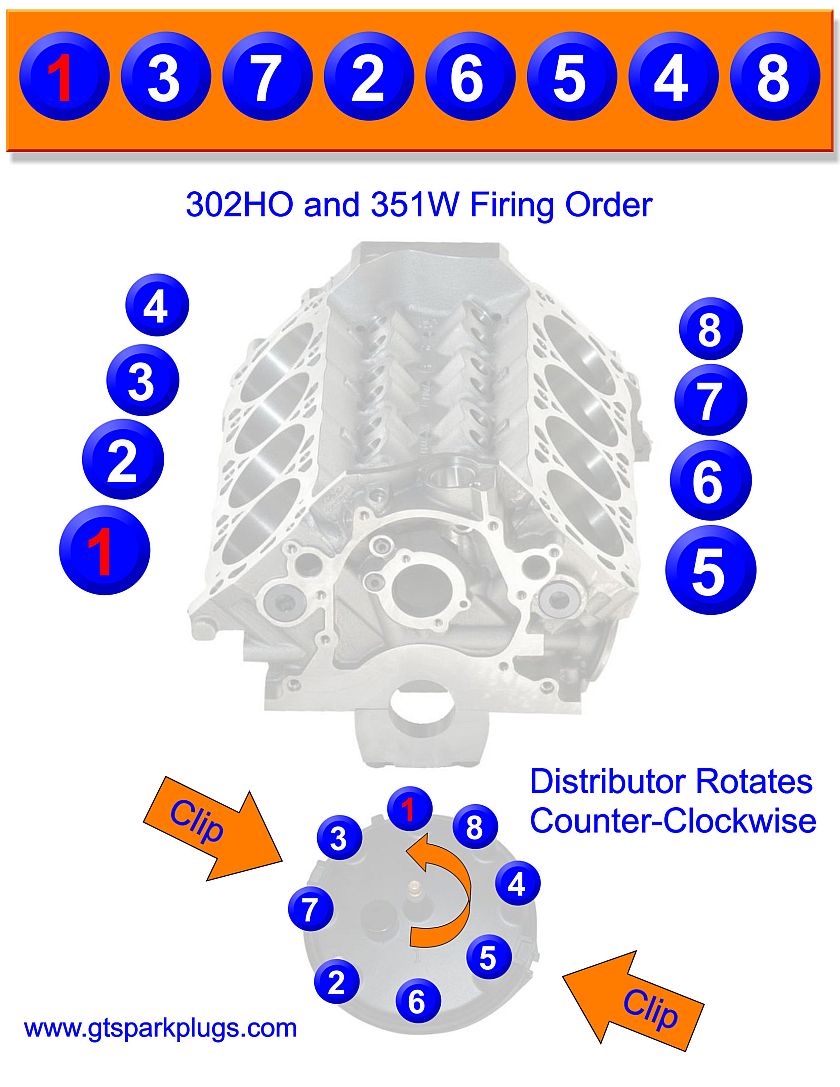

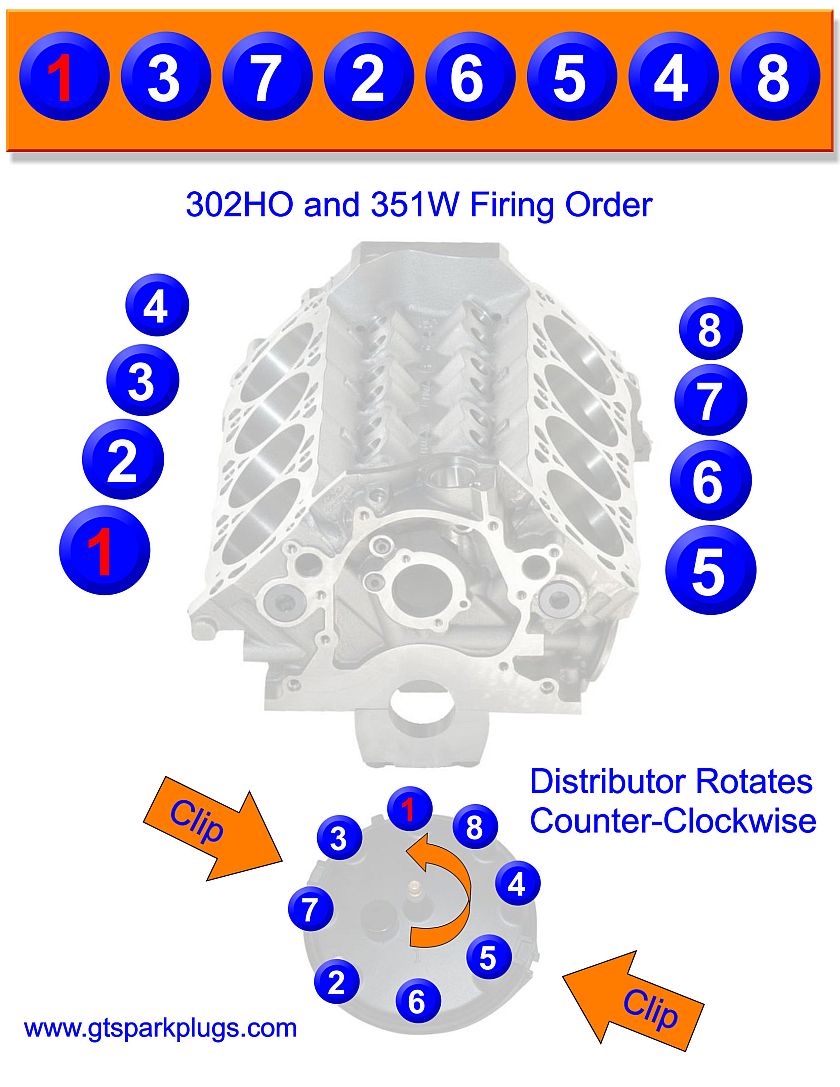

Ford cylinder numbering is different from chevys...

Sent from my iPhone using Tapatalk

Ford cylinder numbering is different from chevys...

Sent from my iPhone using Tapatalk

customcj7

Well-Known Member

blacksheep10 said:#1 moved one (or 2) positions. 360/8 is 45, or it moved 2 positions if you turned it 90 deg (1/4 turn). You could have moved your wires back to where they were. I know you are going to say you put 1 back where it was, does the rotor clock on there different to a key? Does the cap go on different? If the rotor points the same as it did before and the cap orients the same, and the wires went back in the exact same place, I call BS that it was 1/4 turn off. I'd say your wires were 1/8 off meaning one position off.

Rotor is keyed, so it only goes on one way. Cap is only one way as well, it's as screw down cap style (marine distributor) vs clamp. But to be sure, I would think since they are evenly aligned around that it wouldn't matter as it should be the same orientation, but I will look again to verify that is accurate. I don't know.

Fair enough on the 1/4 turn, I'm probably over-exaggerating, but I'm not going to lie, it turned ALOT. Way more than just a slight adjustment like I'd get for a couple of degrees. I was using a timing gun and it wasn't even registering TDC, couldn't even see the mark till I turned it. I've checked the firing order and I do have that accurate, but that's an interesting point if I'm off one. But wouldn't it run like **** if I was? I mean I get no stutter, no rough idle, nothing. Smooth.

pholmann

Well-Known Member

You don't think anything bound up inside do you? Was it advanced or retarded? Timing advance mechanism could have seized waaay advanced.

customcj7

Well-Known Member

Re:

Bound up in the distributor? It has no vacuum advance, and as far as I know should be mechanical advance. If I remember correctly, it was very retarded. But it's been about two months.

To be honest, I have never pulled the timing cover on this puppy, ever. 1989 was when it was dropped in the boat. So I've wondered that as well if the gears are just so slack, or garbage that no matter what, I'm going to be off.

Pretty sure. I'm going off of this schematic for my timing. Looked at a bunch of others and verified them all to be the same.

pholmann said:You don't think anything bound up inside do you? Was it advanced or retarded? Timing advance mechanism could have seized waaay advanced.

Bound up in the distributor? It has no vacuum advance, and as far as I know should be mechanical advance. If I remember correctly, it was very retarded. But it's been about two months.

To be honest, I have never pulled the timing cover on this puppy, ever. 1989 was when it was dropped in the boat. So I've wondered that as well if the gears are just so slack, or garbage that no matter what, I'm going to be off.

Rokcrler said:When you used the timing gun, are you certain you clipped the lead to plug #1?

Pretty sure. I'm going off of this schematic for my timing. Looked at a bunch of others and verified them all to be the same.

customcj7

Well-Known Member

This is the cap I have on my distributor:

http://www.skidim.com/TUNE-UP-KIT-302_351-87-LATER-Prestolite/productinfo/RP173024A/

Here is the Ignitor III module I purchased:

http://pertronix.shptron.com/p/71581-ignitor-iii-for-8-cyl-prestolite

http://www.skidim.com/TUNE-UP-KIT-302_351-87-LATER-Prestolite/productinfo/RP173024A/

Here is the Ignitor III module I purchased:

http://pertronix.shptron.com/p/71581-ignitor-iii-for-8-cyl-prestolite

grcthird

Birmingham, AL

The position of the properly timed distributor when it fired with the points is going to be different than it will with the pertronix setup. Been down that road more than once and it can be aggravating as hell to get set up right.

You may have a leaking exhaust valve or seat or burned valve causing the higher temps on those 2 cylinders that could be contributing to the overheating. Possibly could have burned them when the timing was way out. But I would think it would have some sort of a misfire, running rough, or some other symptom. That's getting kinda thin and grasping straws, worst case type of stuff...

You may have a leaking exhaust valve or seat or burned valve causing the higher temps on those 2 cylinders that could be contributing to the overheating. Possibly could have burned them when the timing was way out. But I would think it would have some sort of a misfire, running rough, or some other symptom. That's getting kinda thin and grasping straws, worst case type of stuff...

redneckengineered

Trailer Park Panty Dropper

Any chance the motor is lean?

All I know is NOBODY pulls a boat motor unless there's something wrong with it.

Was it a salt water motor?

Salt eats ferrous metal for lunch. You could have some paper thin water jackets in that area.

Just remember the basics. That's where you'll find your problem

Was it a salt water motor?

Salt eats ferrous metal for lunch. You could have some paper thin water jackets in that area.

Just remember the basics. That's where you'll find your problem

customcj7

Well-Known Member

grcthird said:The position of the properly timed distributor when it fired with the points is going to be different than it will with the pertronix setup. Been down that road more than once and it can be aggravating as hell to get set up right.

You may have a leaking exhaust valve or seat or burned valve causing the higher temps on those 2 cylinders that could be contributing to the overheating. Possibly could have burned them when the timing was way out. But I would think it would have some sort of a misfire, running rough, or some other symptom. That's getting kinda thin and grasping straws, worst case type of stuff...

Did you have major timing issues from points to petronix as well? Any tips to dial in the timing? I'm going to look for TDC via cylinder #1 and verify with distributor, then mark on my timing strip TDC, then set for 10 degrees BTDC (was factory setting).

Yeah, when the engine is running I have no misfire, no stumbles, no rough idle. I can hammer the motor and she spins up with zero hesitation and sounds smooth as silk.

redneckengineered said:Any chance the motor is lean?

Removed the fuel pressure regulator which put the fuel at higher then Edelbrock prefers, dialed out the settings on the carb to richen it up, and sprayed carb cleaner looking for vacuum leaks, as best as I can tell no. I put the regulator back on, adjusted the carb so my eyes stopped burning from running so rich and no change.

LightBnDr said:All I know is NOBODY pulls a boat motor unless there's something wrong with it.

Was it a salt water motor? Salt eats ferrous metal for lunch. You could have some paper thin water jackets in that area.

Just remember the basics. That's where you'll find your problem

Not exactly true. This was a Supra ski boat that my dad owned. Had it on boat stands while reworking the trailer back in 2000-2001. I kept the boat at my dad's plant. Some little ****ing asshats came in on night just to vandalize. Cut propane lines on the forklifts, spray painted ****, and one of them threw a chain around one of the stands and yanked it out from under the boat. Boat dropped and landed on it's tracking fins and fubar'd the hull. Since it was a classic boat and beyond repair, there was nothing we could do. So there sat a busted hull boat with a 351w, next to a CJ with a 4.2L on it's way out. A few beers and some thinking started the process. Motor was in perfect shape, freshwater all it's life, and has been in my family possession ever since it left the factory in 1989. Boat had 700+ hours on it when pulled.

grcthird

Birmingham, AL

customcj7 said:Did you have major timing issues from points to petronix as well? Any tips to dial in the timing? I'm going to look for TDC via cylinder #1 and verify with distributor, then mark on my timing strip TDC, then set for 10 degrees BTDC (was factory setting).

Yeah I've had to do stuff like that to get them set up correctly before. That should work good, the only issue would be if the timing chain has slack in it.

customcj7

Well-Known Member

Re:

I plan on checking the timing chain while working to find TDC. Thanks for the info, I've wondered if this Pertronix setup has thrown everything off.

I don't think I'm following you. When you say watch the engine vacuum, what do you mean?

grcthird said:Yeah I've had to do stuff like that to get them set up correctly before. That should work good, the only issue would be if the timing chain has slack in it.

I plan on checking the timing chain while working to find TDC. Thanks for the info, I've wondered if this Pertronix setup has thrown everything off.

ROKTOY829 said:Could try watching the engine vacuum, to double check the timing and lean/rich mixture

I don't think I'm following you. When you say watch the engine vacuum, what do you mean?

Zjman

Well-Known Member

- Joined

- Oct 22, 2014

- Messages

- 2,306

I'd say if it ran fine before you swapped out the ignition then I would start there, get a oem ignition back on it and go from there but with those 2 hot cylinders I wouldn't rule out head gasket either

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

84mallcrawl

Well-Known Member

- Joined

- Mar 26, 2014

- Messages

- 220

another stupid question for you. some boat engines turn the opposite direction from automotive engines. The change in rotation is done with the distributor gear and cam lobes. Could the planets aligned when you originally set the engine up and with the ignition change have thrown them out of alignment?

muddinmetal

Guntersville, AL

You need you a nice GM HEI ignition

Zjman

Well-Known Member

- Joined

- Oct 22, 2014

- Messages

- 2,306

I was gonna say same thing and they are pretty cheapmuddinmetal said:You need you a nice GM HEI ignition

Sent from my iPhone using Tapatalk