Welderd

Well-Known Member

- Joined

- Jan 16, 2008

- Messages

- 998

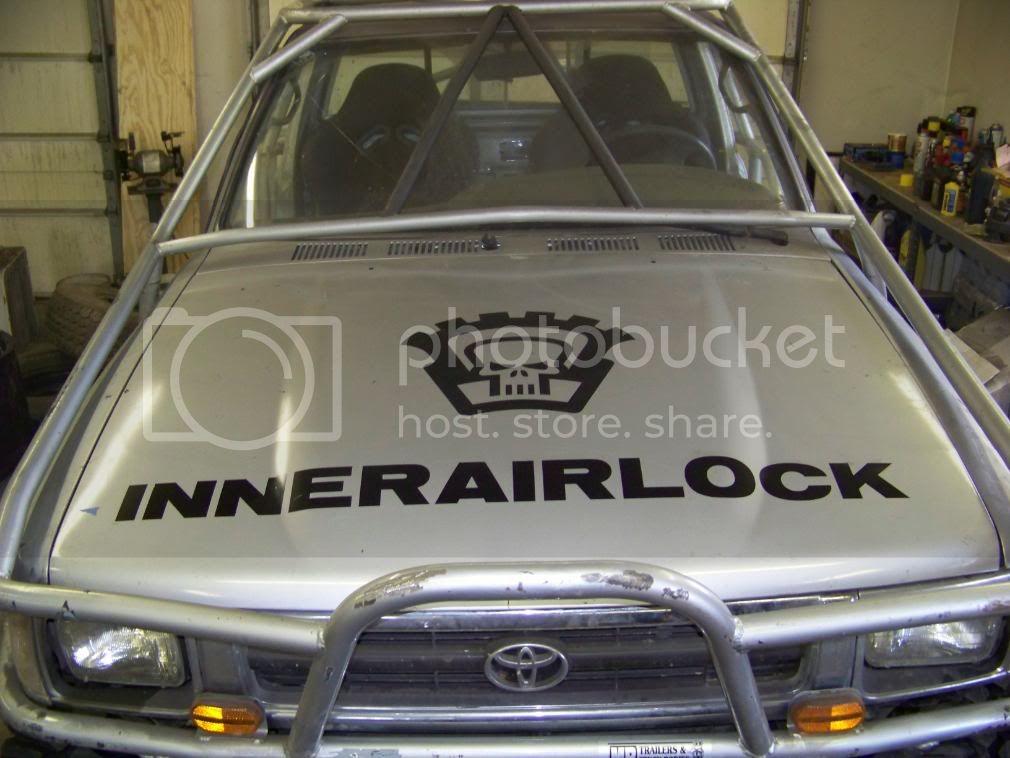

You guys probably know how to install stuff but I gotta pimp my new sponsor and show of a cheaper alternative that's out there now

Inner Airlock Install

Tube info:

This picture shows a heavy-duty tube (nearest) and a standard tube (farthest)

Heavy-duty on the left and standard on the right

(standard tube has powder on it already)

EDIT: I'm not sure anymore which is which!

Both tubes are the same size and there isn't much visible difference between the two. However you can definitely feel the difference in rubber thickness. Both tubes can be purchased at most atv or motorsports stores as they are a typically motocross inner tube. I found that my local store had the standard tubes in stock for $4.25 each and had to order the heavy-duty ones for $15 each and took 2 days. We will be installing 2 heavy-duty tubes in the front tires and 2 standard tubes in the rear. We also picked up a few spare standard tubes for a demo model and just in case.

The Airlocks come with special valve stems to install in your rims

The cuts in the backside of the valve are to allow air to get from the underside of the tube to inside of the tire. Remember these inner tubes are not inflating your tires they only hold the bead on the rim.

Special note: Replace your valve stems! We used rubber valve stems and scored them with a cut-off wheel -- AFTER installing a complete tire and Airlock only to find the valve stem was cut and leaking.

Rubber o-rings are also supplied with the Airlocks

We've found it best to install one o-ring on the inside of the rim and one on the outside of the rim and then use the 2 nuts supplied with the tube to hold the tube valve stem in place and seal the hole.

Note: We tried to leave one nut on the inside of the rim and the other on the outside like you would on a motorcycle tire, but with an aluminum rim this left the valve stem too short to work with the air chuck.

Inner Airlock Install

Tube info:

This picture shows a heavy-duty tube (nearest) and a standard tube (farthest)

Heavy-duty on the left and standard on the right

(standard tube has powder on it already)

EDIT: I'm not sure anymore which is which!

Both tubes are the same size and there isn't much visible difference between the two. However you can definitely feel the difference in rubber thickness. Both tubes can be purchased at most atv or motorsports stores as they are a typically motocross inner tube. I found that my local store had the standard tubes in stock for $4.25 each and had to order the heavy-duty ones for $15 each and took 2 days. We will be installing 2 heavy-duty tubes in the front tires and 2 standard tubes in the rear. We also picked up a few spare standard tubes for a demo model and just in case.

The Airlocks come with special valve stems to install in your rims

The cuts in the backside of the valve are to allow air to get from the underside of the tube to inside of the tire. Remember these inner tubes are not inflating your tires they only hold the bead on the rim.

Special note: Replace your valve stems! We used rubber valve stems and scored them with a cut-off wheel -- AFTER installing a complete tire and Airlock only to find the valve stem was cut and leaking.

Rubber o-rings are also supplied with the Airlocks

We've found it best to install one o-ring on the inside of the rim and one on the outside of the rim and then use the 2 nuts supplied with the tube to hold the tube valve stem in place and seal the hole.

Note: We tried to leave one nut on the inside of the rim and the other on the outside like you would on a motorcycle tire, but with an aluminum rim this left the valve stem too short to work with the air chuck.

- Broke ass SOB's

- Broke ass SOB's

![mms_picture_4[1].jpg](http://attachments.www.hardlinecrawlers.com/xfmg/thumbnail/0/183-24f21a573e1b1595324f93ce14743030.jpg?1625928071)