RogueFab

Well-Known Member

^CLICK on this picture, it is a link to our web page.

The Rogue Fab Tube Bender kit w/dies is only $595! (3.5/4.5 CLR only, 6.0 is an upgrade)

This bender includes the BASE, it includes a built in accurate DEGREE INDICATOR, and it includes (1) 180 degree die!

180 degree Die sets in 3.5-"4.5" CLR are $199 shipped, no sales tax, no handling fees, no sale required... this is every day!

Size range for 3.5 CLR is .5" to 1.125" (1/2" to 1 1/8")

Size range for 4.5 CLR is 1.00" to 1.75" (1" to 1 3/4")

We even have dies that bend 2 sizes at this price! Like our 3/4 and 7/8 round combo die.

Larger 180 degree Die sets in 6.00" CLR are $349-399 shipped:

Size range for 6.0 CLR is 1.00" to 2.00"

Finally there is an affordable solution to bending tube without mounting the bender the ground, buying adapter kits for hydraulic cylinders, or requiring you to rip on a 4 foot bar while you try to read a degree wheel you can't even reach. Our kit comes with EVERYTHING you need except the air/hydraulic cylinder, which is available nearly everywhere at Harbor Freight for about $80 (without paying shipping). Our Rogue Fab Bender bends vertically to save space in your shop. It can bend the first 90 degrees without pulling any pins or using any ratchet mechanism (then you re-pin to bend more). It is portable! This tool is Made in the U.S.A. out of US made metal/materials and packaged in US made boxes. We back our rock-solid engineering with the fastest shipping and best customer service and tech support in the industry. We will ship your order in 1 business day 99% of the time. Don't take our word on the customer service, call us and see for yourself: 503-389-5413.

Our benders can keep up with your business. We offer our tube benders fully assembled and powder coated (additional cost), and with complete tooling packages and professional 1200+ lb capacity bender carts for large fabrication shops. We also have a 2HP double acting fully engineering electric/hydraulic power system that has 2 adjustable auto stops for precision manufacturing of repeat parts. We get absolutely amazing rates on LTL freight. We would be happy to get your tools palletized and delivered to your loading dock.

VIDEOS OF OUR TOOLS<--- LINK

Here is our bender on one of our Elite carts with the optional 2HP Electric Hydraulic upgrade and optional 195 degree adjustable Auto Stops (We also have a mount that attaches our VersaNotcher to our carts):

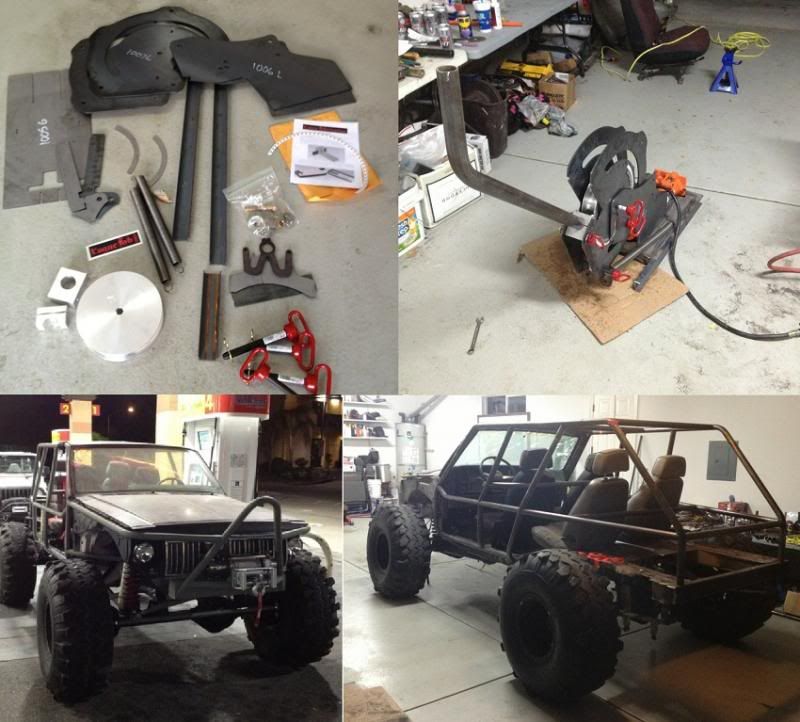

We have 30+ dies that fit this bender. There are many options to allow you to bend 4130 Chromoly, Pre-Polished stainless (including low carbon 316) without a scratch, aluminum, and of course pipe, square tube, DOM, HREW, and solid bar stock. Did you notice the chunk of 1.75 SOLID ROUND BAR bent to 90 degrees?:

Here is our tradesman set, $1649 as a weld together kit without the $80 ram, with a range of dies from 1 inch to 2 inch (1/4" sizes). That is a bender AND (5) 180 degree dies for $1649! (2.00x6.00, 1.75x6.0, 1.50x4.5, 1.25x4.5, 1.0x3.5)

Here is the $595 weld together kit (shown assembled and painted):