Thanks man!

Someone asked about the driveshaft parts on another board so I'll post the info here too.

They are 1.625" - 10 spline stuff sold by Neapco. I believe they're sold as PTO shaft. I found them a few places online, but I got them through my local Fleet Pride and they beat everyone online.

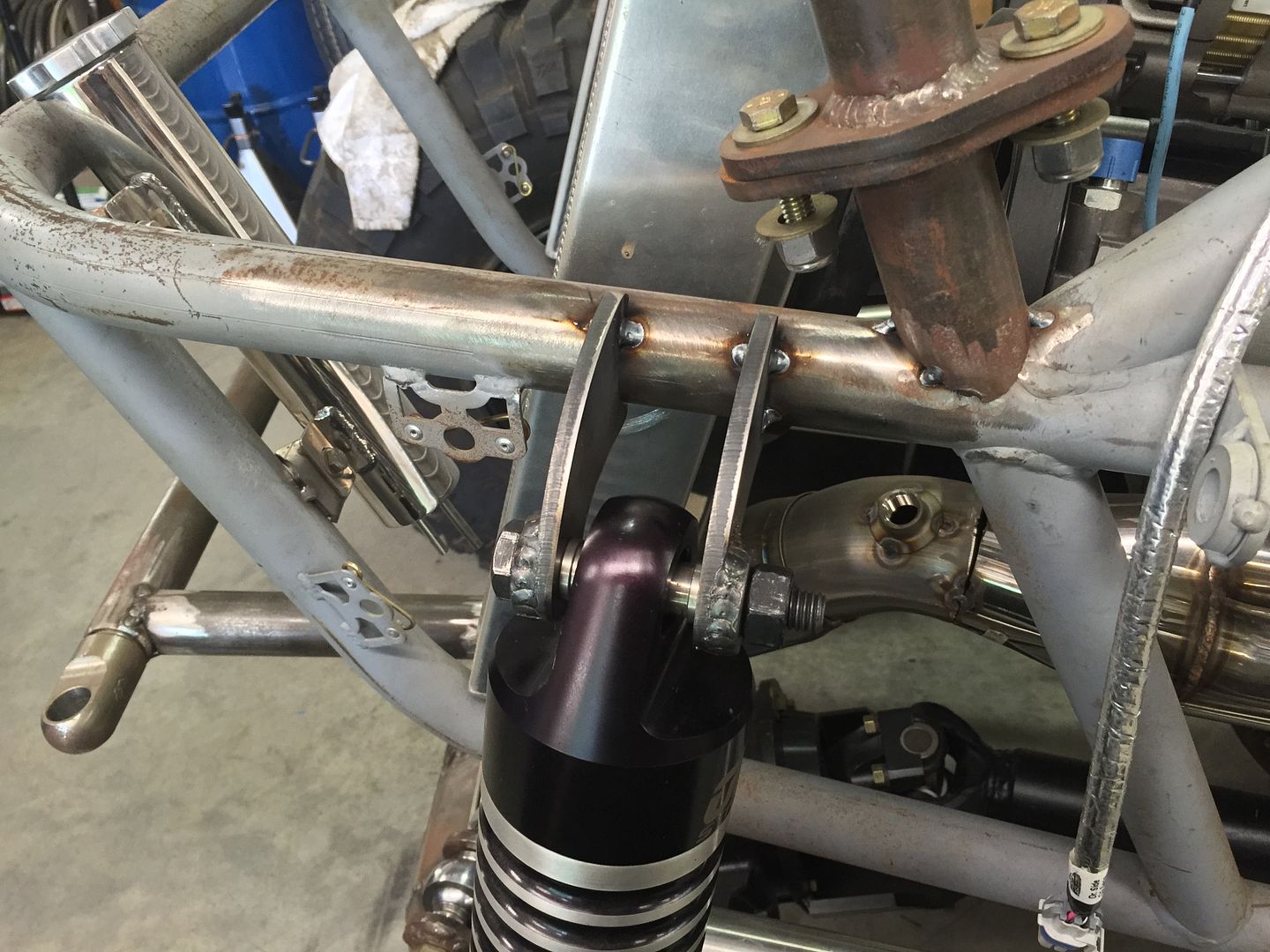

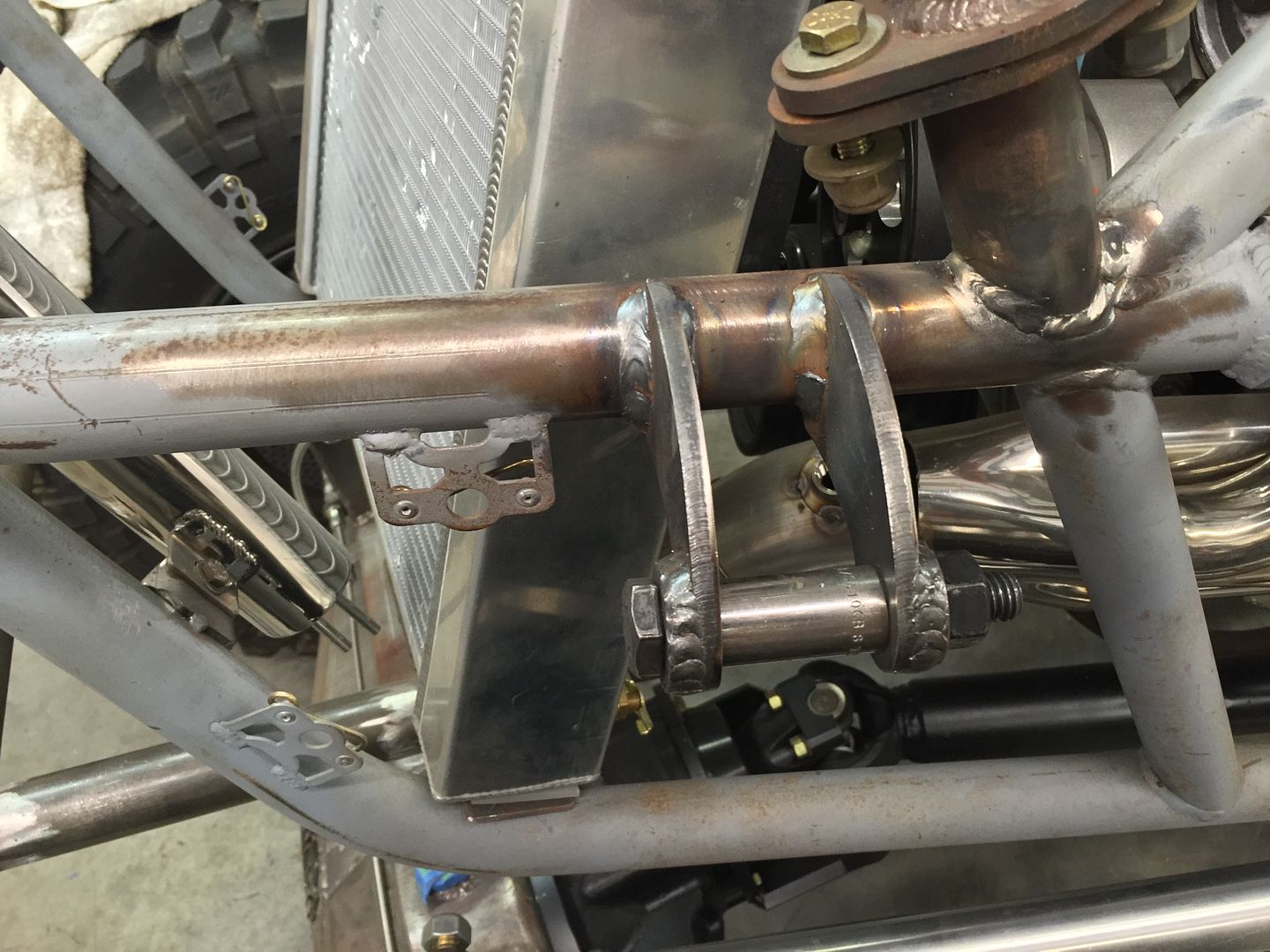

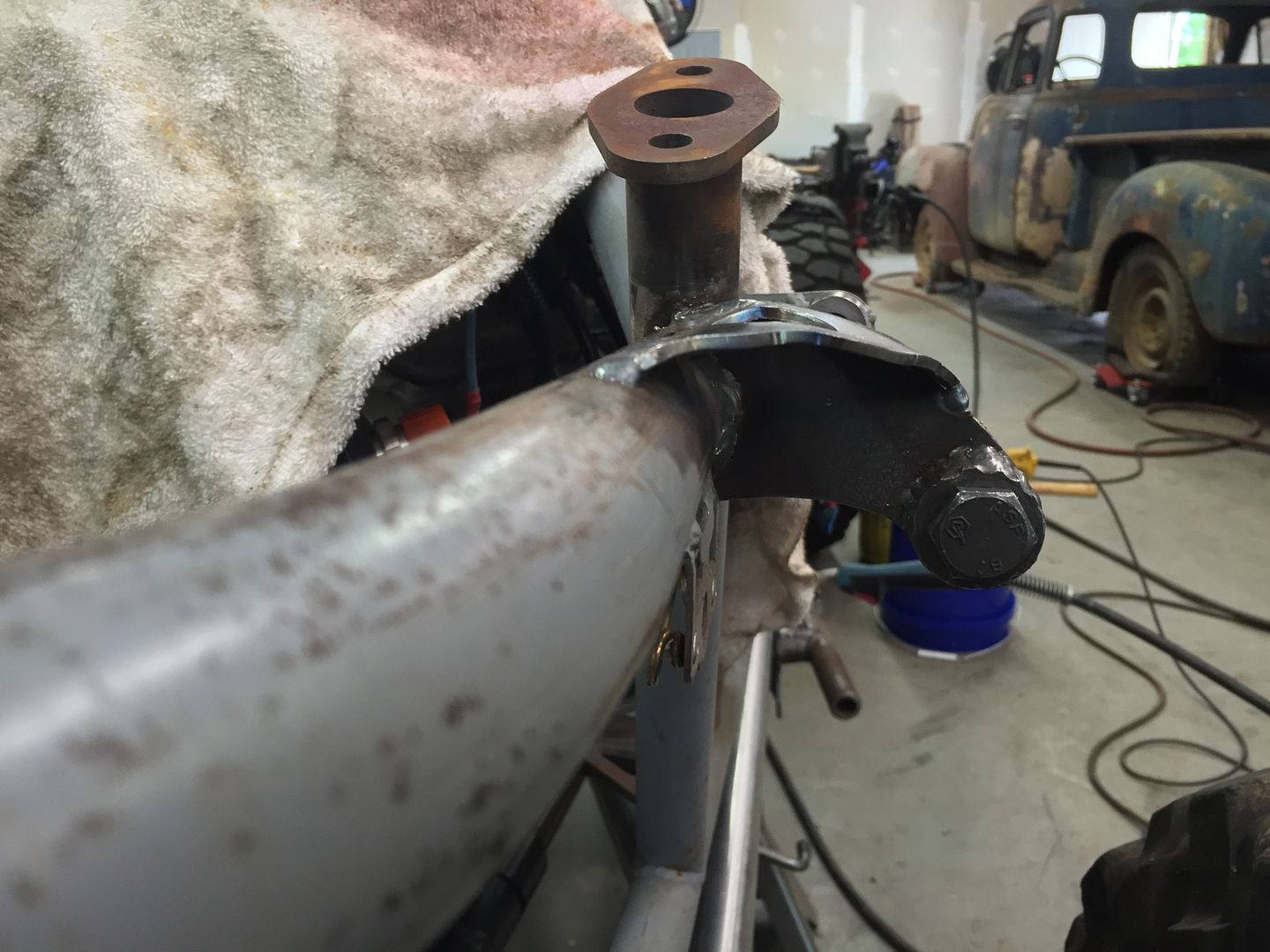

The slip spline shaft is 28" overall with about 2" of smooth shaft on the end. I originally bought two, but ended up cutting them in half. The smooth part of the shaft is 1.375" o.d. So to mate it to the yoke I put it inside a piece of 1.75" x .188 DOM and the put that inside a piece of 2" x .120 DOM. It took a little grinding and a press, but it all fit together good.

The coupler is 2" o.d. I used 2.5" x .250 tubing, probably way overkill. And the yoke on that end also has a short piece of 2" x .120 tubing slipped inside the 2.5"

Here's the part #s:

Shaft-Neapco #72-2231 or possibly 2231-3

Coupler-Neapco #53-2415

Yokes-Spicer #3-28-777