redneckengineered

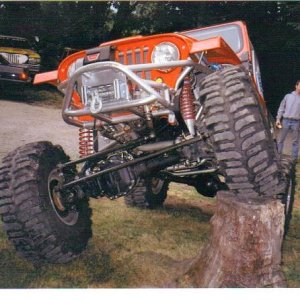

Trailer Park Panty Dropper

Where do you guys lift from on your tube chassis? I've been using the upper link mounts but I'm still playing with locations. It takes a few minutes to get the pads just right. My lift is fairly new and I haven't been using it long so I'm still learning what it's like not to work on my back. Post pics if you got them and any tips/tricks to make life easier.

Noted. I have a forklift for those kind of shenanigans.

Noted. I have a forklift for those kind of shenanigans.