Beerj

Sonzabitches!

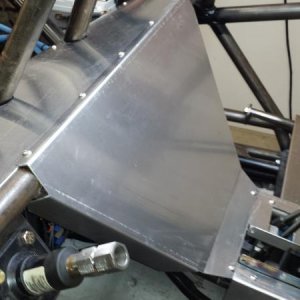

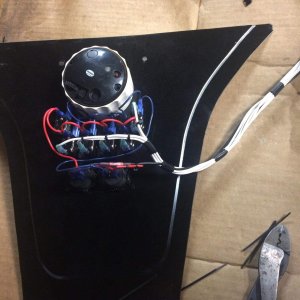

Couple of crappy, dark and cluttered pics from today. No more jack stands! It's being sucked down with straps here because the spring rates are a little too high. I was shooting for 7" of shaft showing and ended up with 8.5" in the front and almost 9.5" in the back. Although the rear is going to have almost 100 lbs added between the fuel cell and gas. These pics are with the shocks at mid travel and the belly at 22.75" but that will be a little less with the skid on. I'll try to get some better pics tomorrow in the daylight.

But it's surely exciting seeing it at this point though I I know there's still a huge list of things that need to be done. I think the light is there, just really dim.

But it's surely exciting seeing it at this point though I I know there's still a huge list of things that need to be done. I think the light is there, just really dim.