Okay, I'm going to bestow a little knowledge for those that think DOM is the beats all. (it CAN be the best material)

Dom has a seam, its drawn out while its being Drawn Over a Mandral.

There are different types of DOM.

Structural DOM is NO good for a cage. so just because its DOM does not mean its worth a crap.

Stuctural DOM has as little as 1/3rd flash weld (ya, not full penetration) do you think thats good? DOM can be Hot rolled or cold rolled.

If you want good DOM, it needs to be COLD ROLLED and must be MECHANICAL DOM. (and should be atleast 1020(80ksi) or 1026 (87ksi).

nobody here has touched on 1026 CREW (cold rolled electric weld) people think that because you can see the seam, its no good. well thats BS.

1026 Crew is about 65KSI. (1020 / 1018 is about 60ksi)

people are alos saying that HREW in the right design is OK, but in all honesty its crap for what we use, bends easy. (and only 45ksi)

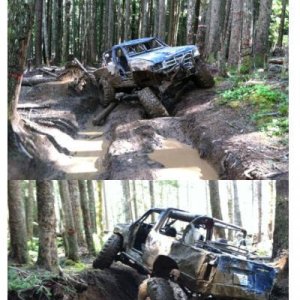

My EXO cage is :rb: but ts functional. its make of 1026 CREW. (1.5 x .120)

It has survived a roll and it was drug on its roof for about 20 feet. Wll it survive a roll such as the toyota at naches.. No way. I would lke to see a cage (other than a nascar Cromoly cage) hold up to that fall. I highly doubt any cage would.

But i get crap for it because its not DOM, Yet it is stronger than "stuctural DOM"

and Pipe, A500 pipe is stronger than HREW, or sturctural DOM.

The main difference from pipe to tube is pipe is measured fromt the ID and is not as TRUE (because of fabrication tolerances) while Tube is measured from teh OD and is much more "true". The reason we use tubing in mechanical applications is because pipe, but on a lathe or machine tents to wip around because of (for lack of a better word) trueness tolerances.

So the next time somebody says I'm building your Cage from DOM, ask them

what kind of DOM?

(FYI CREW is half the price of mechanical DOM and 75% as strong. While HREW is Very cheap but only 56% as strong as mechanical DOM)

:beer: