Yup....

I somehow end up in most of the Transaxle discussions...

I am confused why there is a mental barrier to many.... when it comes to using a transaxle. This is just more proof of how good it works!

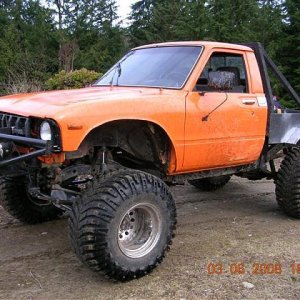

I have been running my Mazda rig since 2005!

Marv

I somehow end up in most of the Transaxle discussions...

I am confused why there is a mental barrier to many.... when it comes to using a transaxle. This is just more proof of how good it works!

I have been running my Mazda rig since 2005!

Marv