2days in to a 4 dayer.... LOL

So I am more an artist than anything.

May not be super gusseting, but looks cool!I am going to attempt to dimple them a skosch to add ridgidity..(ball peens and a prayer!)

First time TEsting the fit of a Subie motor in a TOyota...

from the front bumper fly view.....Now mind you this is the first test fit before the tunnel is cut out, to see where the three main issues I know are going to be like(exhaust, starter , and finally steering)

Now, It appears that I need to cut out the tunnel and move it ALL up a skosch...

YEAH, thats not a skosch!:haha:

AFter trial and error, dropping everything out so I could cut more etc, It took all day to finally get everything to where I wanted it maintaining the rest of the heat box and such.

The starter is gonna be a cunthair from the GO pedal....That will be interesting.

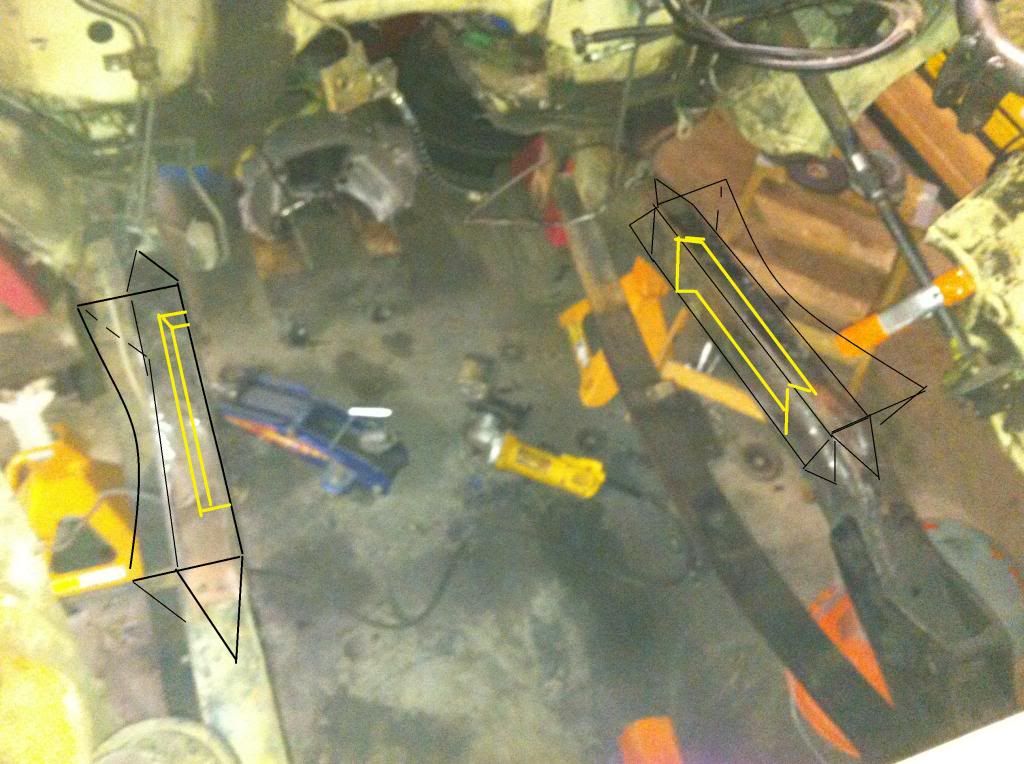

The whole trans got moved forward about 6 inches .The sharpie marks on the floorboard are where the front and back of the "shifter mounts"were located stockish.

That moves it out to where I have room for my shift fork, and only the very ass end of the starter will go through the firewall.

AND I don't have to remove and replace my tunnel hoop (no big deal anyway I guess)Just one less thing..

Exhaust stud clearance, MAn this is barely there.But with a custom header I imagine I will just barely sneak right by.

So with all of that done(I know , seems like so little )

)

I decided I needed to start on the T-case mount.I had picked up a FROR style plate from pos97tj last week thinking it would work easier when I got to this point.BUt it turns out that the stock mount is literally about 2-3 inches above bottom of frame rail.So, I opted to start making my own mount.Started working things out and then fried a small hole saw:haha: trying to slot the back for access holes..

The hole saw before it's demise....:redneck:

WElp,thats where I am at after last night.Gonna go get a hole saw and continue on the T-case mounting mission.Then on to the Engine hangers....

I'd defenitely say it is flatbellied ...

cheers

So I am more an artist than anything.

May not be super gusseting, but looks cool!I am going to attempt to dimple them a skosch to add ridgidity..(ball peens and a prayer!)

First time TEsting the fit of a Subie motor in a TOyota...

from the front bumper fly view.....Now mind you this is the first test fit before the tunnel is cut out, to see where the three main issues I know are going to be like(exhaust, starter , and finally steering)

Now, It appears that I need to cut out the tunnel and move it ALL up a skosch...

YEAH, thats not a skosch!:haha:

AFter trial and error, dropping everything out so I could cut more etc, It took all day to finally get everything to where I wanted it maintaining the rest of the heat box and such.

The starter is gonna be a cunthair from the GO pedal....That will be interesting.

The whole trans got moved forward about 6 inches .The sharpie marks on the floorboard are where the front and back of the "shifter mounts"were located stockish.

That moves it out to where I have room for my shift fork, and only the very ass end of the starter will go through the firewall.

AND I don't have to remove and replace my tunnel hoop (no big deal anyway I guess)Just one less thing..

Exhaust stud clearance, MAn this is barely there.But with a custom header I imagine I will just barely sneak right by.

So with all of that done(I know , seems like so little

I decided I needed to start on the T-case mount.I had picked up a FROR style plate from pos97tj last week thinking it would work easier when I got to this point.BUt it turns out that the stock mount is literally about 2-3 inches above bottom of frame rail.So, I opted to start making my own mount.Started working things out and then fried a small hole saw:haha: trying to slot the back for access holes..

The hole saw before it's demise....:redneck:

WElp,thats where I am at after last night.Gonna go get a hole saw and continue on the T-case mounting mission.Then on to the Engine hangers....

I'd defenitely say it is flatbellied ...

cheers

Last edited: