Rjhoward32006

Well-Known Member

How much is too much?

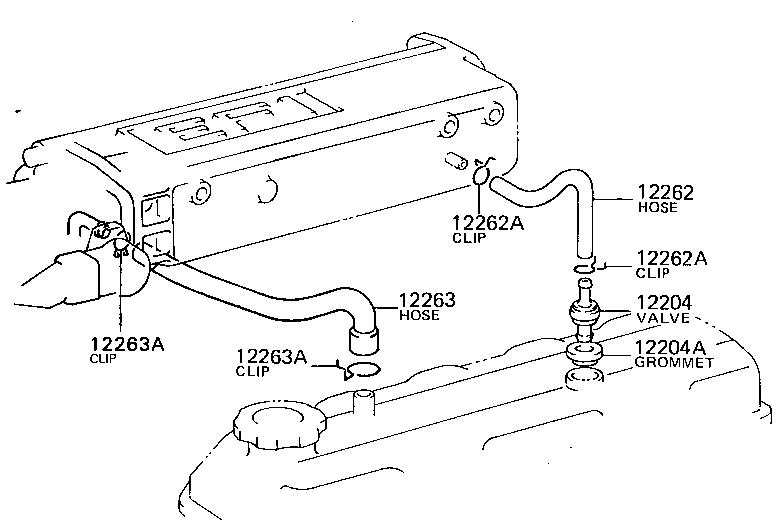

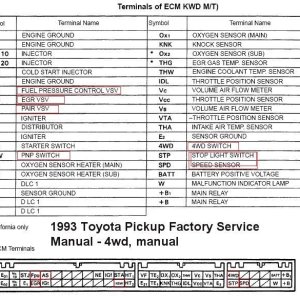

I sealed my dipstick and all ports to the engine.

Installed a pcv catch can for roll-overs and now i'm getting what seems like a good amount of negative pressure. Will put a vaccum gauge in the dipstick tonight to measure. Do any of you seen this before once the engine is sealed up tight? Only bad thing i could think of it hurting is pulling oil away from pistons/ wristpins and things like that because of not as much splash affect?

Someone?

Anyone?

I sealed my dipstick and all ports to the engine.

Installed a pcv catch can for roll-overs and now i'm getting what seems like a good amount of negative pressure. Will put a vaccum gauge in the dipstick tonight to measure. Do any of you seen this before once the engine is sealed up tight? Only bad thing i could think of it hurting is pulling oil away from pistons/ wristpins and things like that because of not as much splash affect?

Someone?

Anyone?