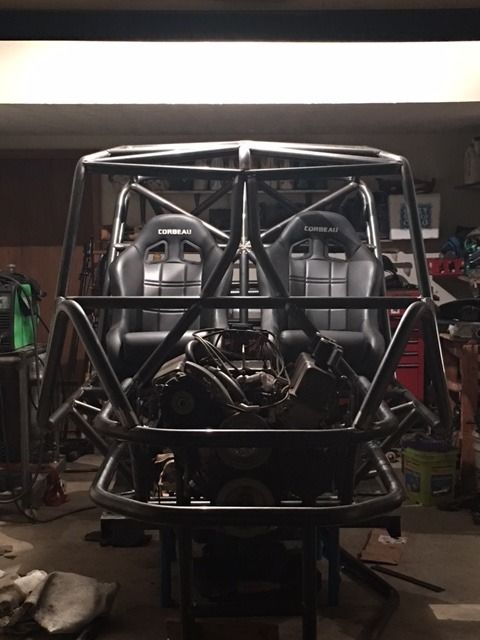

Been slacking on updates lately. The small tedious stuff just isn't as interesting or fun I guess.

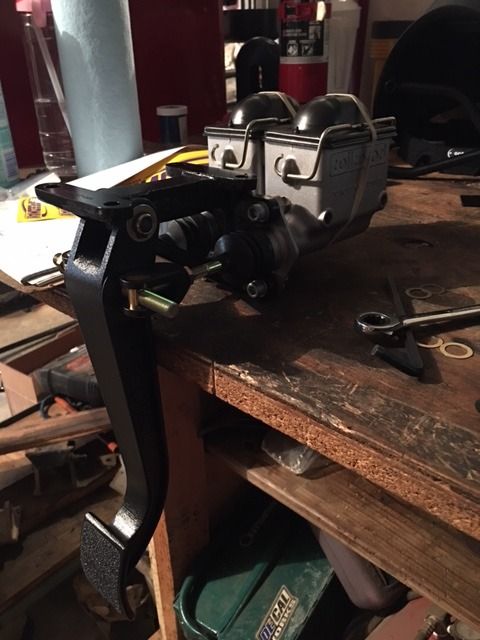

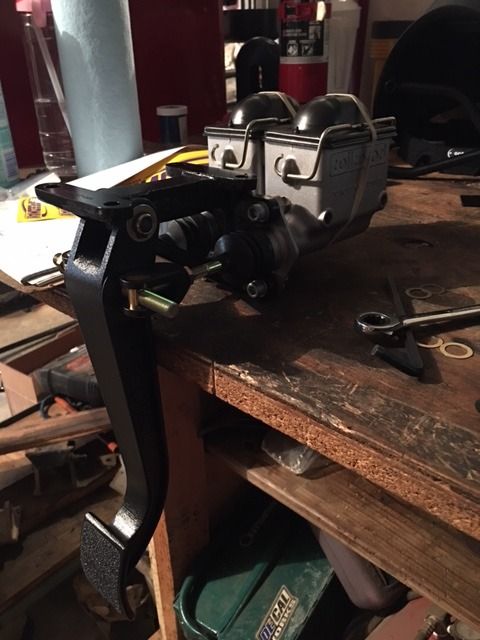

Got the brake pedal and masters mounted up, Wilwood dual 7/8 I think is what I went with. It's been a few weeks. I'm not too crazy about how the fitment went, mainly because I didn't plan ahead and I had to cut a section of tube out to get it in the right spot.

The go pedal is mounted up. I've still got to get a throttle cable and get it set up. I just got one of those cheap "racecar" pedals from Speedway, I'll probably end up modifying it. I'm thinking of cutting it down on the top side to fit under a dash panel and adding some sort of plate so I have a bigger pad for my heavy foot to land.

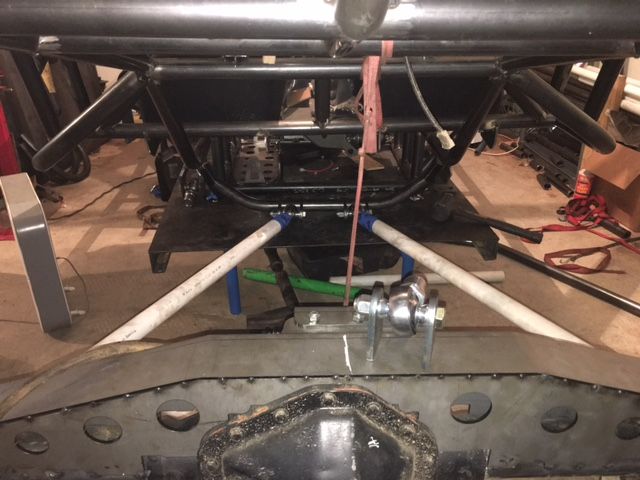

Made a little center console thingy for the shifters. I have full range of motion for the trans shifter, but I can't reach the triple sticks for the tcases while strapped in tight. My Toyota was the same way, I usually had my passenger shift in that anyway. Usually when riding around I'll pick tcase gears at base of a hill or obstacle and then tighten the shoulder belts down.

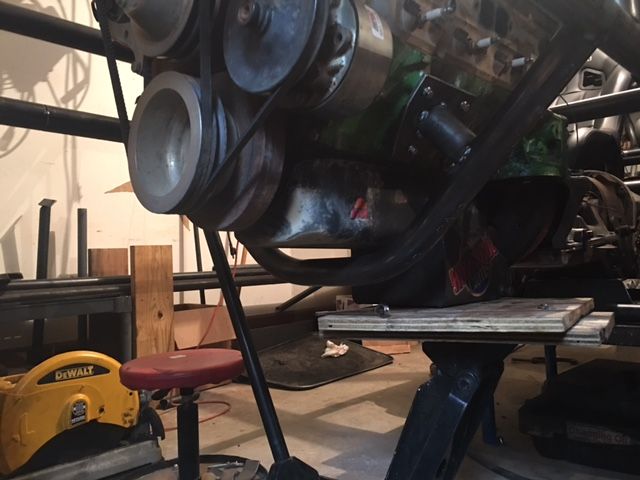

Also go the radiator and propane tank weldered up in place.

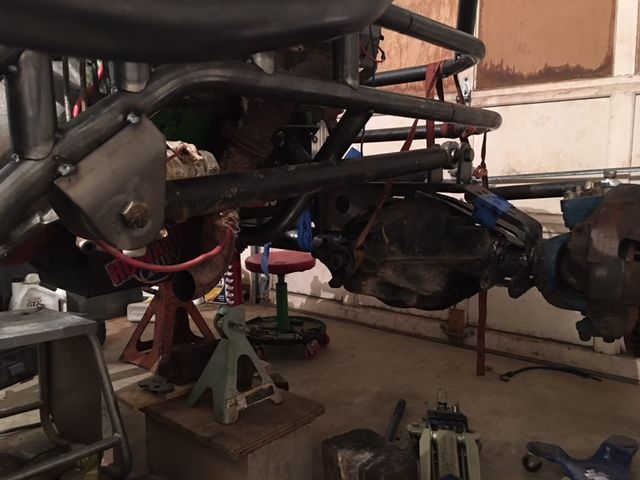

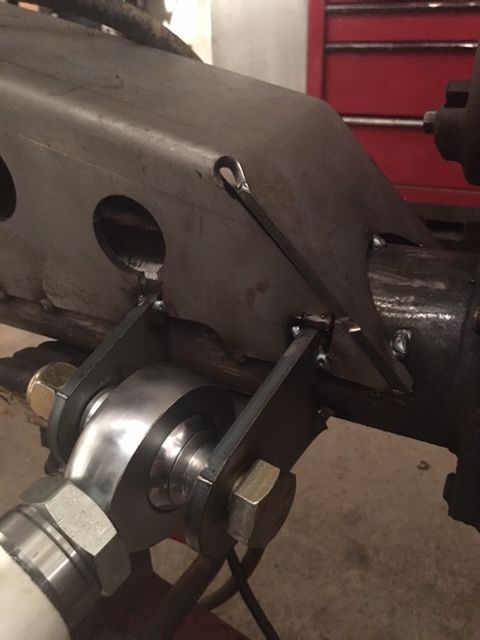

Last update is the rear axle. Got the spring perches cut off and all cleaned up. Then tacked the RuffStuff truss in place.

Next I need to get the front axle in place and start mocking up the links and shock mounting.

Was planning on welding aluminum tabs and using bushings to mount the radiator. But I decided against testing my stick AL stick welding skills on my radiator and just hacked up and re-purposed my old mount. It worked before, so I'm sure it'll work again.

Oh and did I forget to mention the bling?

Hit up Ryan from Accutune Offroad and got the shocks and springs ordered. Ended up getting Fox 16" 2.0 remote resi. Ryan was great to deal with especially since I basically told him I wanted 16" coil overs and that's all I knew. Gave him some info to get an idea of weight and #whatnot, then he did his thing with the custom tune and setting up spring rates. I'm really excited to see how well they work. Springs should be here in a week or so I believe.