the_white_shadow

Well-Known Member

- Joined

- Dec 25, 2014

- Messages

- 816

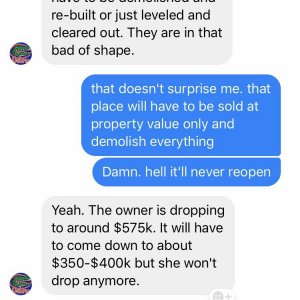

Heres the situation: Trying to install new reid knuckles and reid bronze bushings in my chevy 60, but they are SUPER tight when i clamp on the high steer arms. (Using the 4wheelsupply springless steel arms). The disk that sits on top of the bushing and under the high steer arm is 3/16" thick. I put in the stock nylon bushing and it sits below the top face of the knuckle and the bronze bushing sits above that surface. Right now i have the high steer arm bolted up to where the knuckle can still be turned by hand, but still very tight. If i clamped it all the way down it took me to kick the knuckle to move it. Everything is greased up and in the correct orientation. Talked with Reid and they said their bushings are supposed to sit below the knuckle but I cant see a way for that to happen.

Ive read that the bronze bushings need to "bed in" to the kingpin. But I find it hard to believe that things are supposed to be that tight. Do i just clamp the arm down all the way and let things work loose? Then set the preload with the adjusting bolt on top? Or do I tighten the arms to where I can still turn the knuckles by handm, let the bushings bed in, then re-tighten things to the proper preload?

Mainly I dont want to ruin some expensive parts before i even get to use them. Anyone running this combo? What are your experiences?

My Setup:

Ive read that the bronze bushings need to "bed in" to the kingpin. But I find it hard to believe that things are supposed to be that tight. Do i just clamp the arm down all the way and let things work loose? Then set the preload with the adjusting bolt on top? Or do I tighten the arms to where I can still turn the knuckles by handm, let the bushings bed in, then re-tighten things to the proper preload?

Mainly I dont want to ruin some expensive parts before i even get to use them. Anyone running this combo? What are your experiences?

My Setup:

Hopefully this works. Any advice appreciated.

Hopefully this works. Any advice appreciated.

![IMG_3652[1].JPG](http://attachments.www.hardlinecrawlers.com/xfmg/thumbnail/4/4977-89909798ecaea1f81f71948203478510.jpg?1625928498)