Dillehay

Well-Known Member

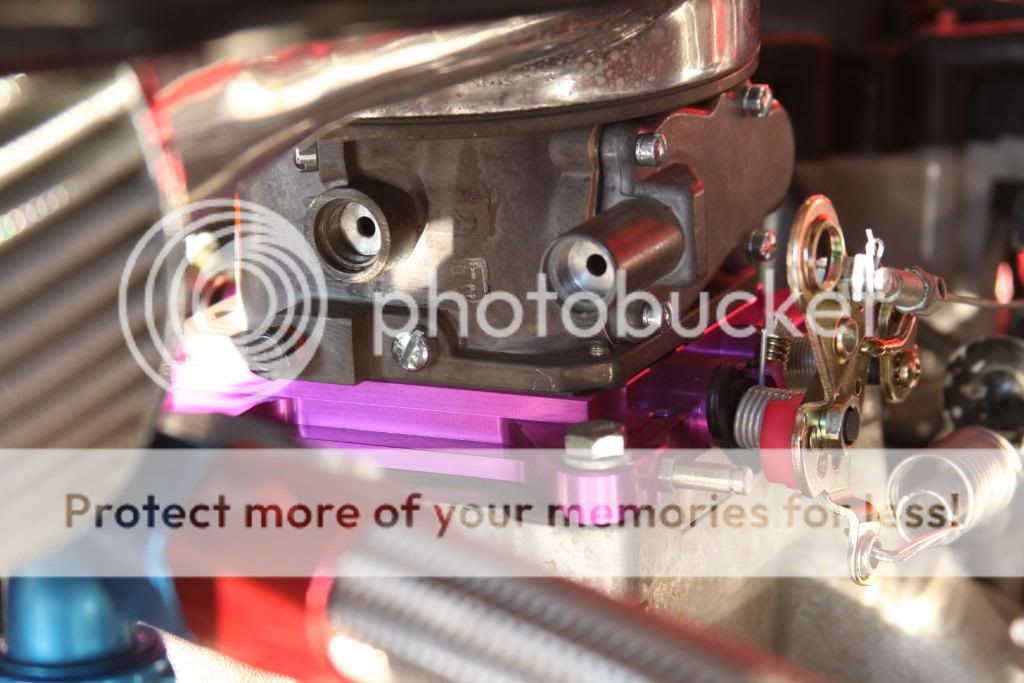

Here's the story:

Once upon a time two county boys wanted to build a tube buggy, build not buy. So that's were we started.....Took a lot of pic's of others buggys, talked to Jimmy Smith, Brian Cole, Timmy Cameron, Essential Off Road, Hell we talked to anybody that would talk to us. We wheeled any chance we got and watched how the other buggys worked. Wrote the ideas down and finally started bending tube. We got Timmy involved in between his (three) buggy builds (holy **** he built three while we were still working on one). It took us so long because Kelly (Dougs wife and banker) would hide money from us, we sold scrap, Kelly's Toyota Truggy, Dougs racing 4-wheeler, a few cows and pretty much anything not bolted down or needed for this build. I'm going to start in reverse engineering mode, i.e. pics of finished buggy and then the build. If you like please say so, if you don't be very very quite. You may hurt our feellings ;D

First I'd like to thank a few,Timmy Cameron, Scotty Hoffman, Junior Phillips, Shane Watkins, Joe Matlock, Mo Crutcher, Troy Crutcher, Amos, Jay Johnson and Kellye Hayes (Dougs wife and the financier of project) Lisa Dillehay (my wife for putting up with late nites and grease) if I misspell name sorry, if I leave somebody out that thinks they did something positive remind me. PD

Here are the pics. I've got a bunch. Thanks for looking.

First time out of the shop on its own power

I'll post more later so I don't over load the thread.

Once upon a time two county boys wanted to build a tube buggy, build not buy. So that's were we started.....Took a lot of pic's of others buggys, talked to Jimmy Smith, Brian Cole, Timmy Cameron, Essential Off Road, Hell we talked to anybody that would talk to us. We wheeled any chance we got and watched how the other buggys worked. Wrote the ideas down and finally started bending tube. We got Timmy involved in between his (three) buggy builds (holy **** he built three while we were still working on one). It took us so long because Kelly (Dougs wife and banker) would hide money from us, we sold scrap, Kelly's Toyota Truggy, Dougs racing 4-wheeler, a few cows and pretty much anything not bolted down or needed for this build. I'm going to start in reverse engineering mode, i.e. pics of finished buggy and then the build. If you like please say so, if you don't be very very quite. You may hurt our feellings ;D

First I'd like to thank a few,Timmy Cameron, Scotty Hoffman, Junior Phillips, Shane Watkins, Joe Matlock, Mo Crutcher, Troy Crutcher, Amos, Jay Johnson and Kellye Hayes (Dougs wife and the financier of project) Lisa Dillehay (my wife for putting up with late nites and grease) if I misspell name sorry, if I leave somebody out that thinks they did something positive remind me. PD

Here are the pics. I've got a bunch. Thanks for looking.

First time out of the shop on its own power

I'll post more later so I don't over load the thread.