slravenel

Well-Known Member

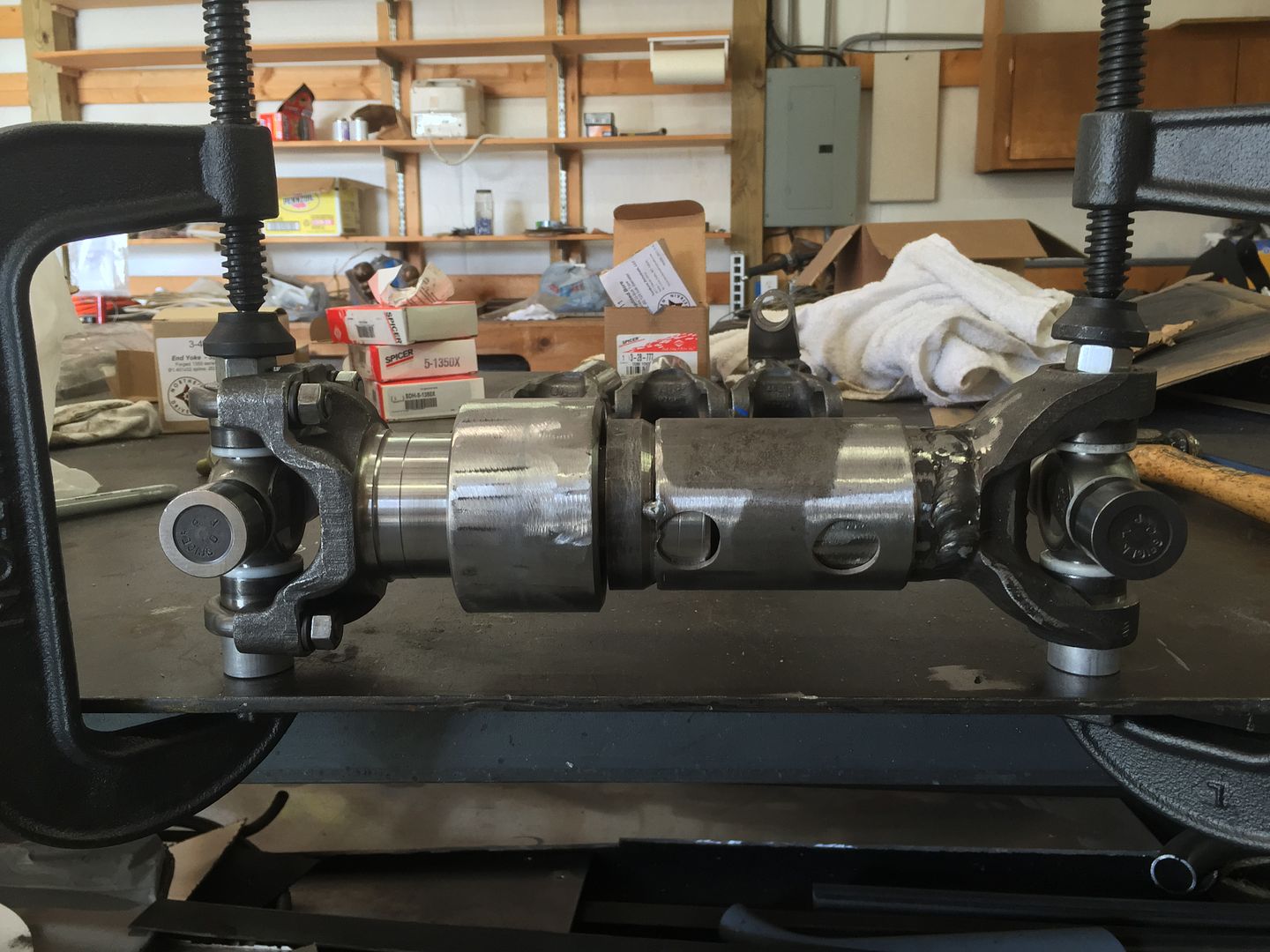

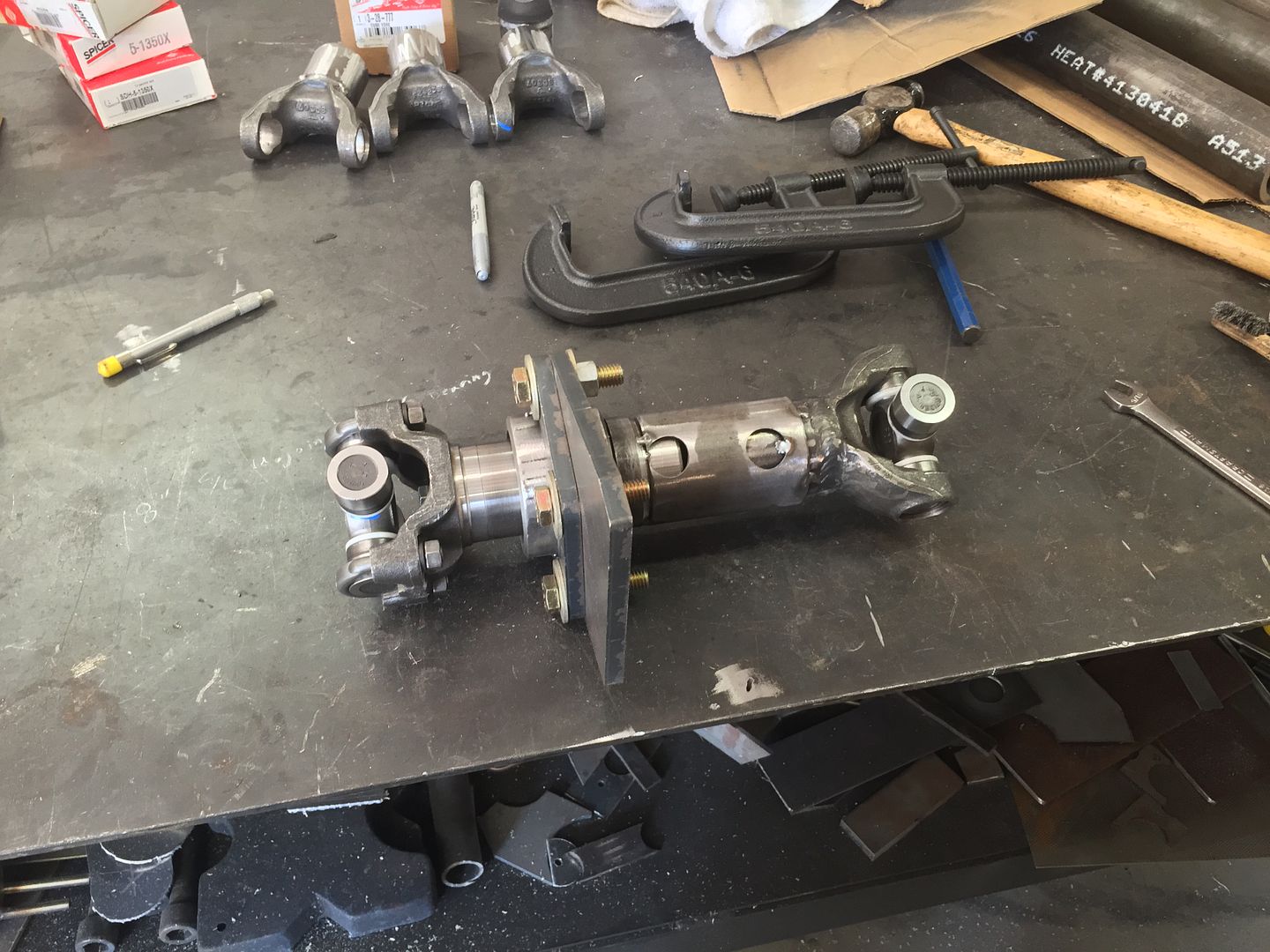

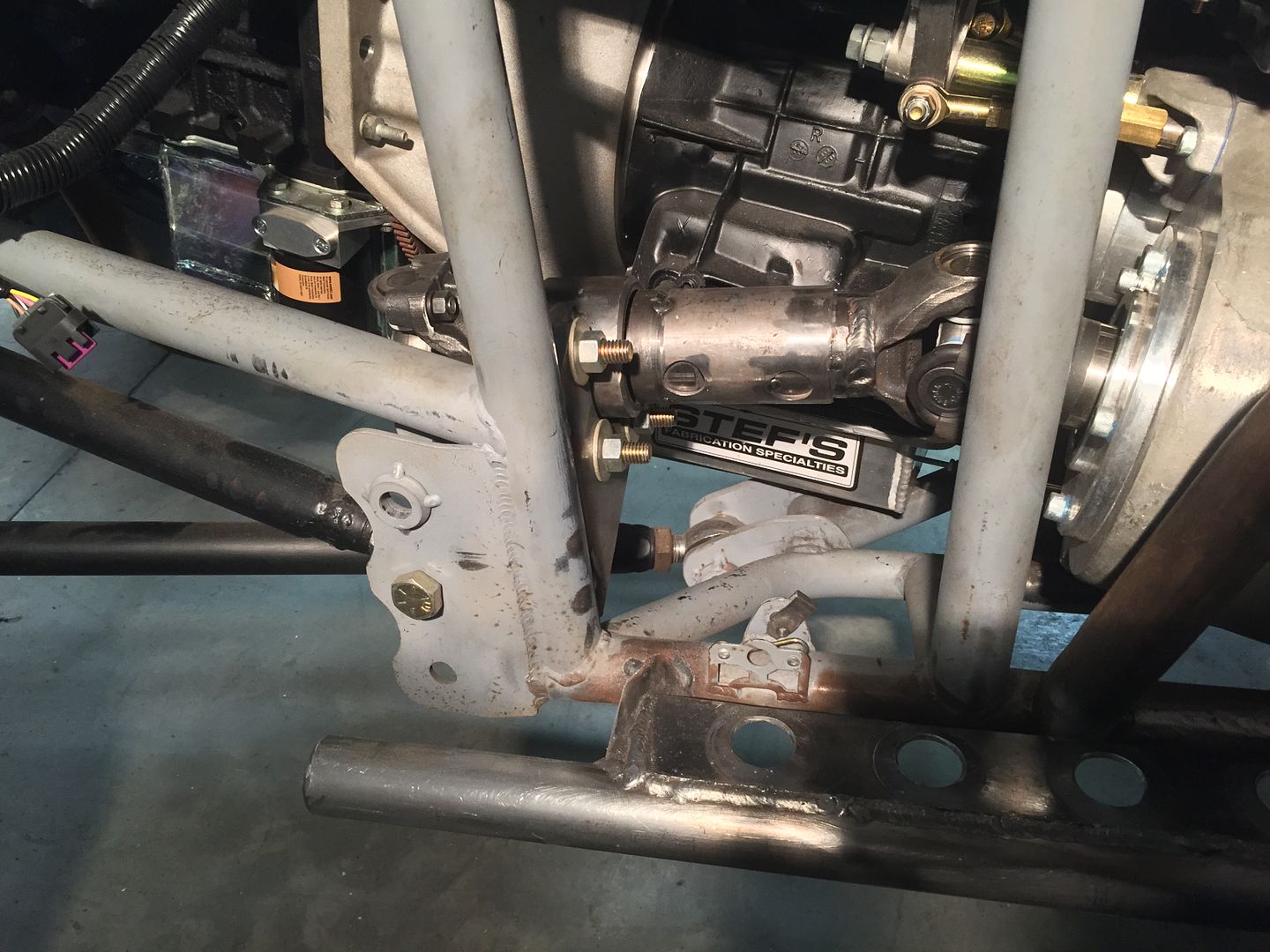

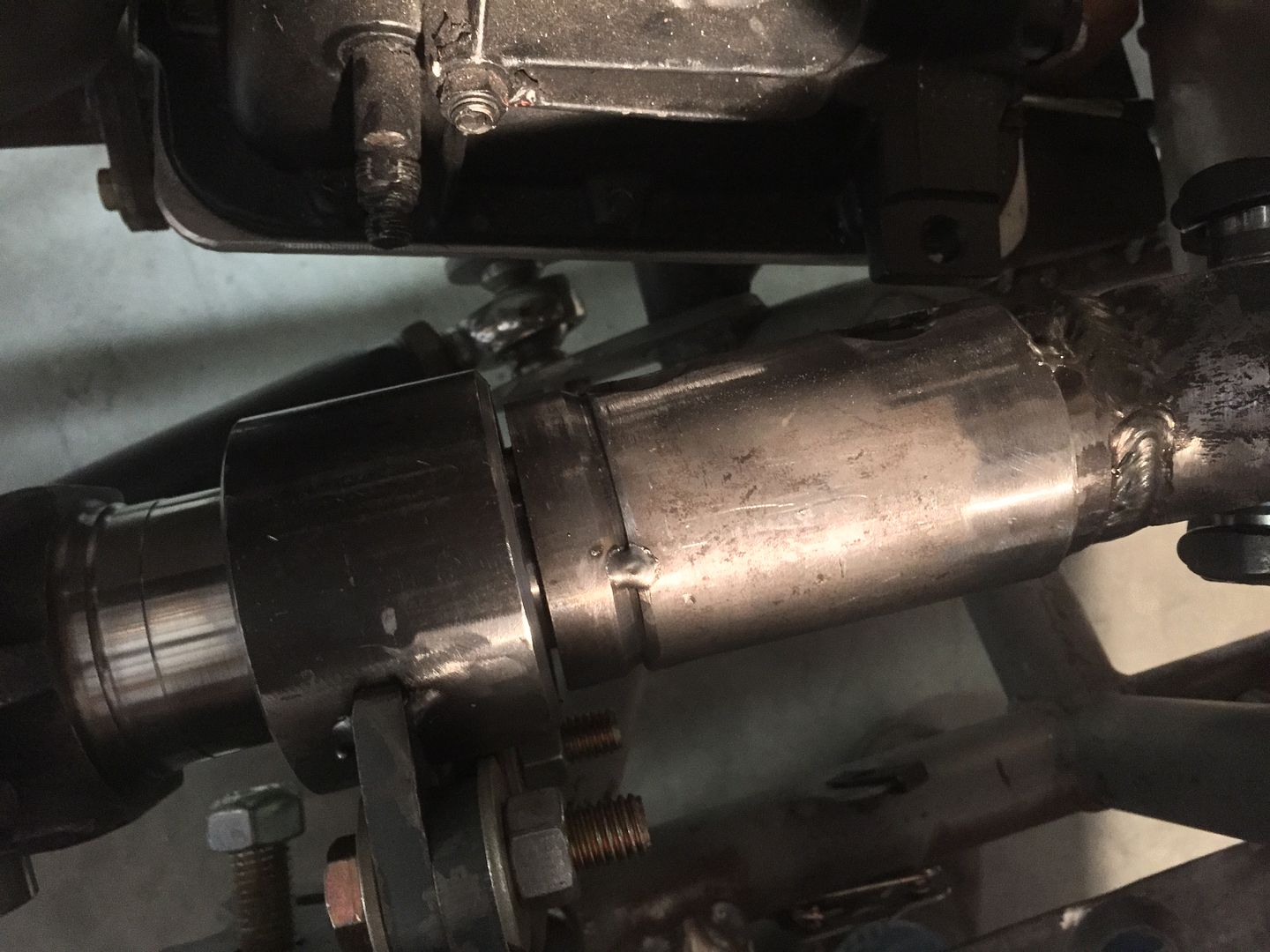

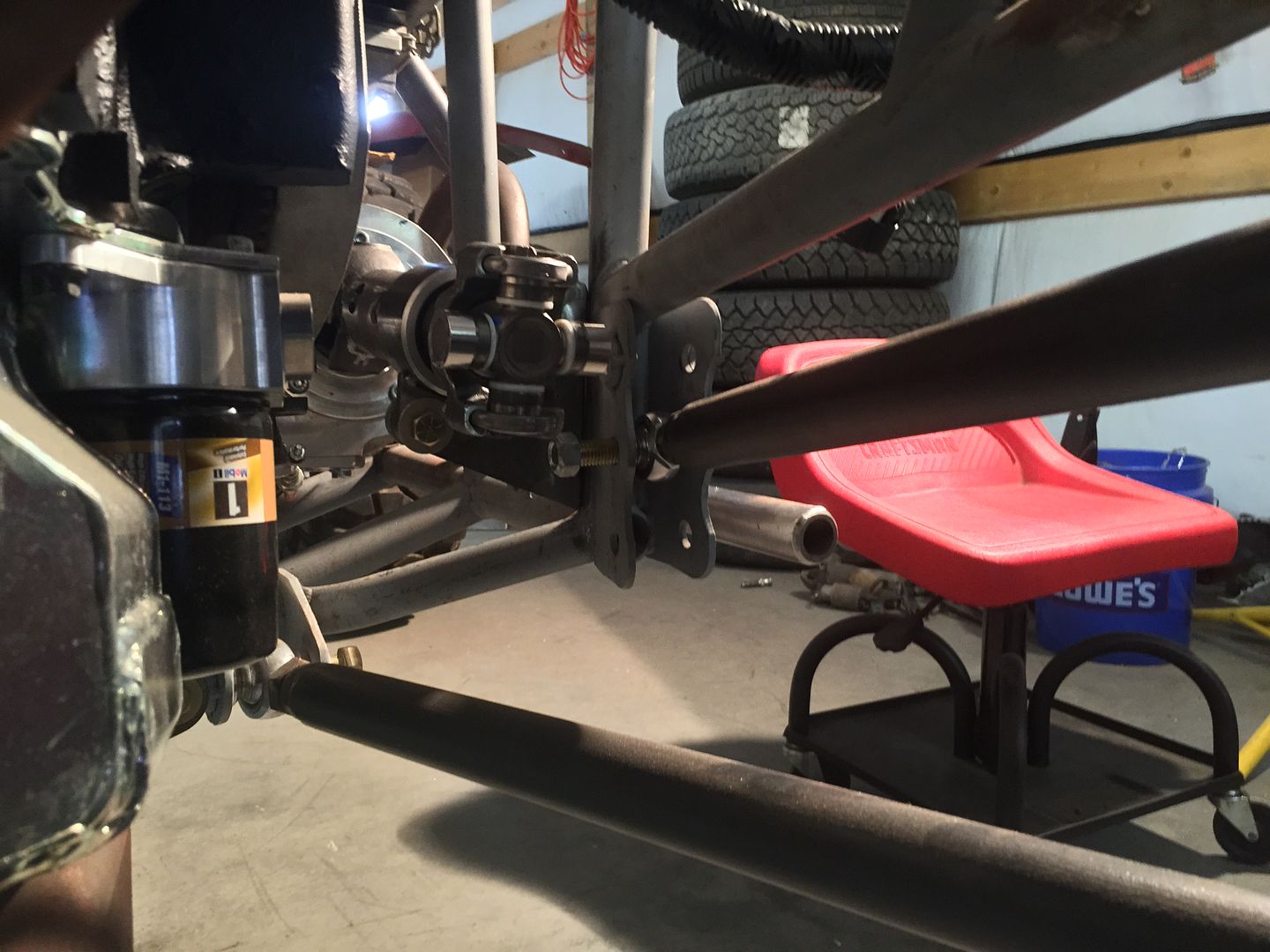

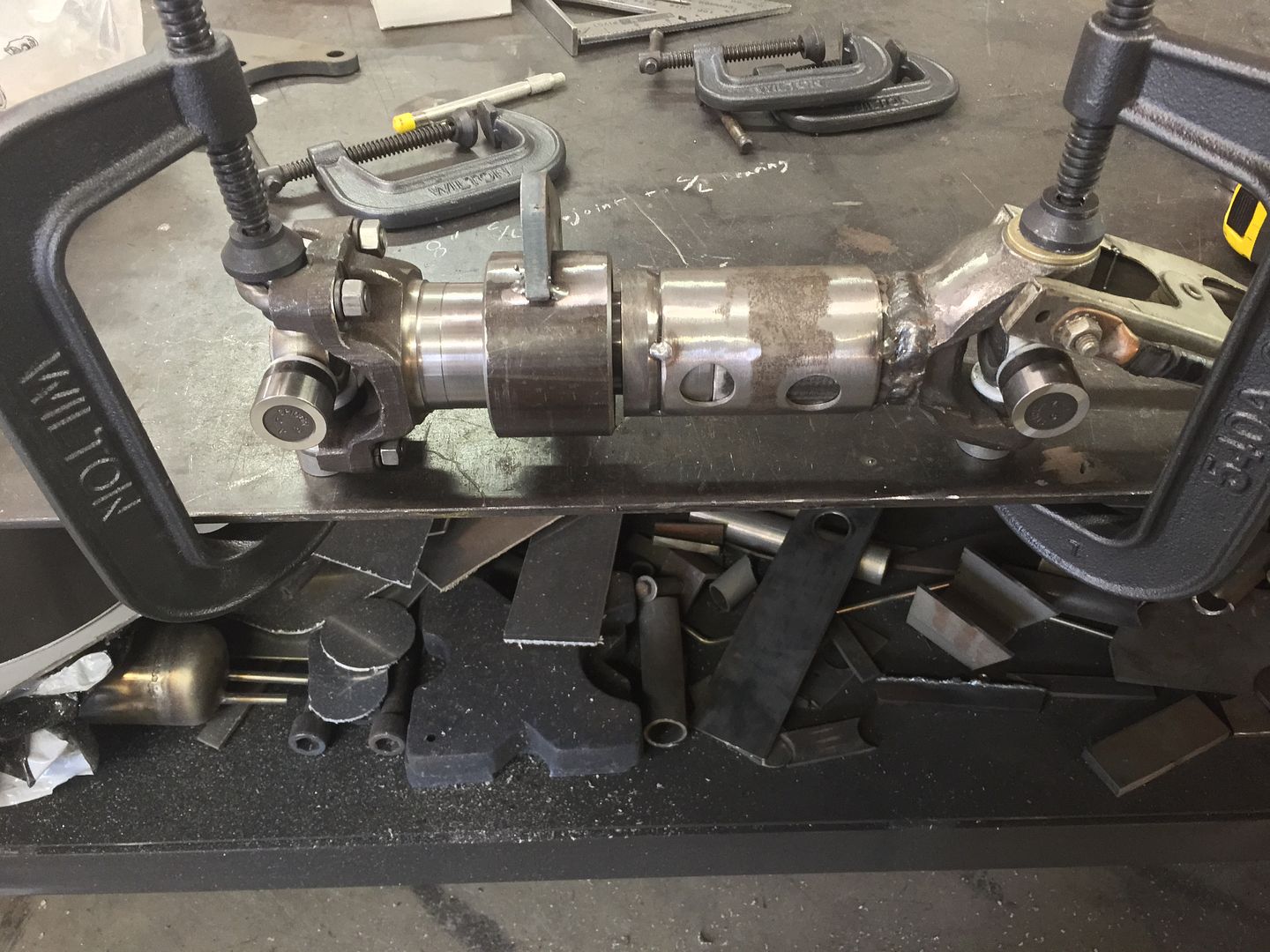

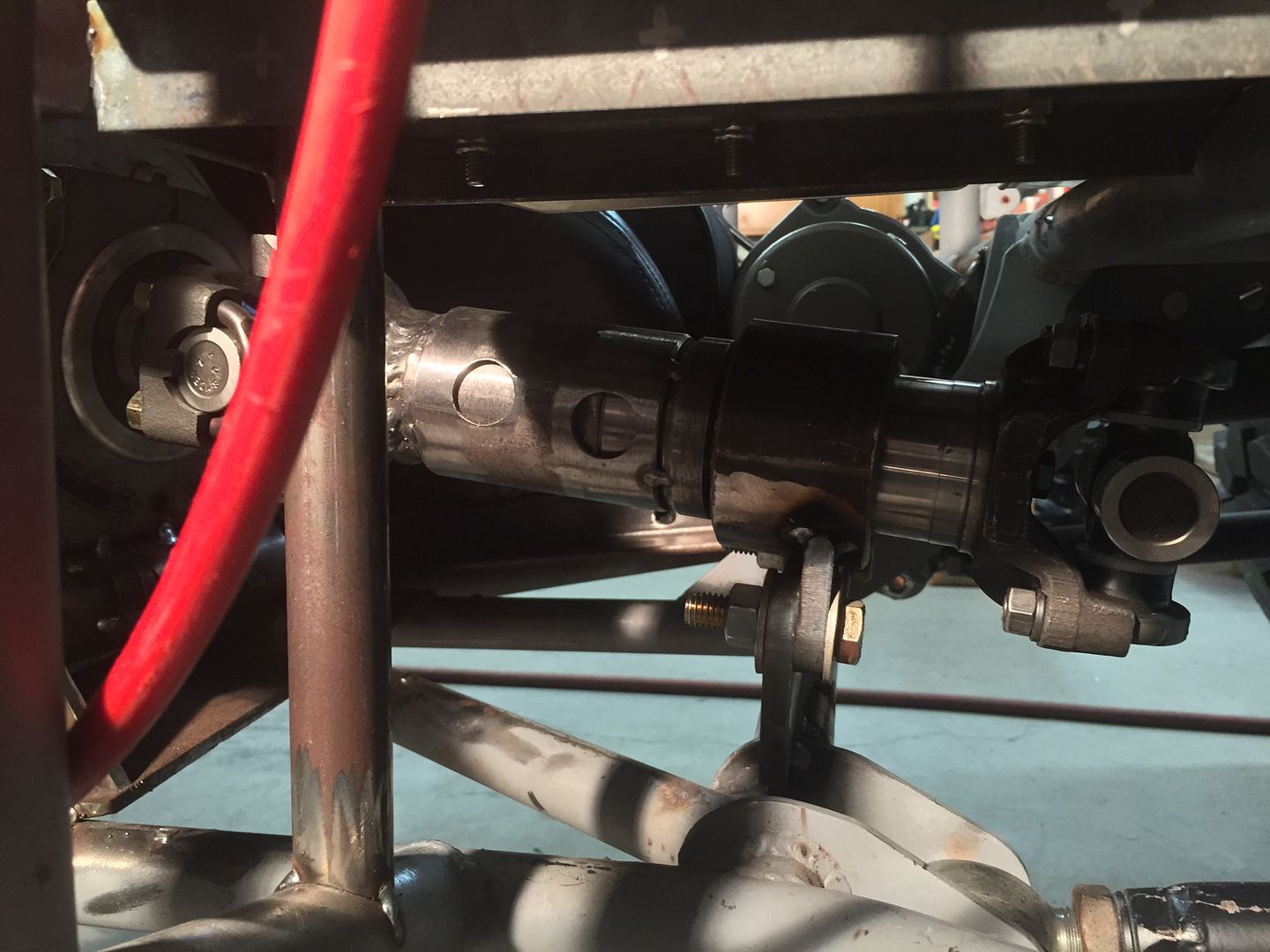

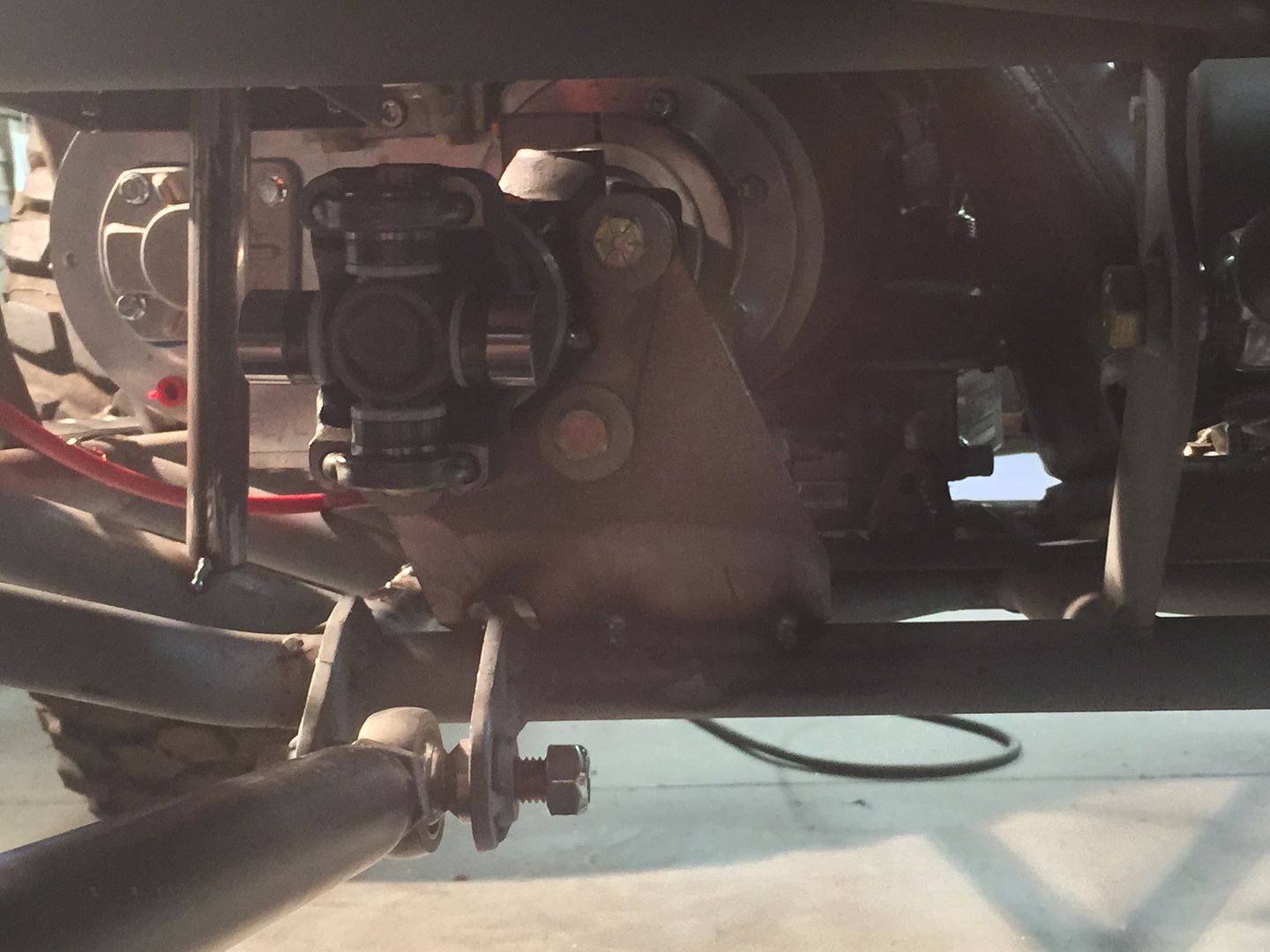

Using the single DS bearing from WOD on my buggy build, but am having some issues getting the right size yoke for the midshaft at the Atlas end.

http://www.wideopendesign.com/Product/11196/Drive-Shaft-Carrier-Bearing.aspx

1350 yoke on the Atlas.

The end of the WOD bearing is 2.25OD which is all fine and well....tubing to fit that is easy. But I cannot for the life of me, find a 1350 weld on yoke anywhere that has a 2.25 OD...

Where are you guys getting the right tubing / yoke combo from?

Thanks!

http://www.wideopendesign.com/Product/11196/Drive-Shaft-Carrier-Bearing.aspx

1350 yoke on the Atlas.

The end of the WOD bearing is 2.25OD which is all fine and well....tubing to fit that is easy. But I cannot for the life of me, find a 1350 weld on yoke anywhere that has a 2.25 OD...

Where are you guys getting the right tubing / yoke combo from?

Thanks!