J

Joc

Guest

Long story short my ram started leaking not long after I traded for the rig. I dont know what brand or model number it is to have got a rebuild kit so I just bit the bullet and got a new one at TSC.

My problem is the old one was ****** rigged to work with the help of some pipe, a heim, and a welder.

It is setup to bolt to the hi steer arm behind the tie rod.

Current leaky ram

Undoing the handy work on the old ram

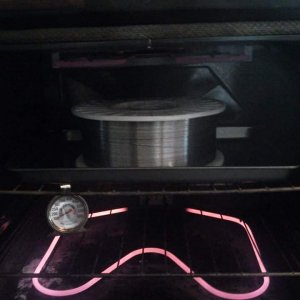

New ram

That is how things came to a hold up. I originally thought the extension was just welded to a nut that was threaded on the ram shaft. WRONG! It was welded so I cut it all loose and was hoping to find a nut that would fit the new ram so I could weld it back to a nut and not **** up a new ram. Well I cannot find a hex nut that will fit the dang thing. TSC dont have any, fastenal doesnt either. A 1" doesnt fit, and a 1 1/8" threads on but is too big b/c there is slop in it. Maybe its a Metric and Im just SOL b/c fastenal said they would have to order it and Im not sure what it is to be ordering anything.

Talked to a buddy and he said I could weld a mount to the tie rod with a mount in the pic below. Only problem is the hole is 3/4" and I need on with a 1" hole.

Mount

Welding a plate to the tie rod seems like the way to go and just use the clevis on the new ram but so far I havent found one online with the right size hole. Plus it looks like it will be welded right on the end where the heim is.

So other than finding a plate to weld on I got 2 options. Weld the crap to the new ram or cut the ears off the clevis and weld to it as if it were the hex nut.

Comments/suggestions

My problem is the old one was ****** rigged to work with the help of some pipe, a heim, and a welder.

It is setup to bolt to the hi steer arm behind the tie rod.

Current leaky ram

Undoing the handy work on the old ram

New ram

That is how things came to a hold up. I originally thought the extension was just welded to a nut that was threaded on the ram shaft. WRONG! It was welded so I cut it all loose and was hoping to find a nut that would fit the new ram so I could weld it back to a nut and not **** up a new ram. Well I cannot find a hex nut that will fit the dang thing. TSC dont have any, fastenal doesnt either. A 1" doesnt fit, and a 1 1/8" threads on but is too big b/c there is slop in it. Maybe its a Metric and Im just SOL b/c fastenal said they would have to order it and Im not sure what it is to be ordering anything.

Talked to a buddy and he said I could weld a mount to the tie rod with a mount in the pic below. Only problem is the hole is 3/4" and I need on with a 1" hole.

Mount

Welding a plate to the tie rod seems like the way to go and just use the clevis on the new ram but so far I havent found one online with the right size hole. Plus it looks like it will be welded right on the end where the heim is.

So other than finding a plate to weld on I got 2 options. Weld the crap to the new ram or cut the ears off the clevis and weld to it as if it were the hex nut.

Comments/suggestions

I ordered the mounts yesterday at 11:30 and they was sitting on my door step today at 1:29 this afternoon. THATS SOME SERVICE :****:

I ordered the mounts yesterday at 11:30 and they was sitting on my door step today at 1:29 this afternoon. THATS SOME SERVICE :****: