Some of you may have seen this build already but hey, I'm turning into a forum whore......

This is the beginning of the next project for me. The old lady wants to ride along with the kids and the "Cooter" wasn't going to cut the mustard in that department. So out with the old and in with the new.

The plan so far; SAS the front, run the 22r with propane, rear leafs (hybrid mazda pack?), 39.5 Irocks on bead-locks, use the tube I bought for a int. cage, and most importantly MAKE IT AS LOW AS I CAN.

I plan on this being a trailer rig that will get beat into submission. Who knows, maybe it will turn into a buggy down the road like I originally wanted to build?

Nice and clean eh?

Stop looking at my *****...

Low-rider..............

I hope my neighbors are not trying to sell their house.

I want to let everyone know this right now, I will never do a SAS to a IFS truck AGAIN if the purpose is to make the most capable wheeler that I can.

This is a link to the reason why http://www.pirate4x4.com/forum/showthread.php?t=599542

P.S. Two wheel drive trucks have the same frame dimensions as a pre 86 4x4. Next time I will just convert a 2wd or start with a pre 86.

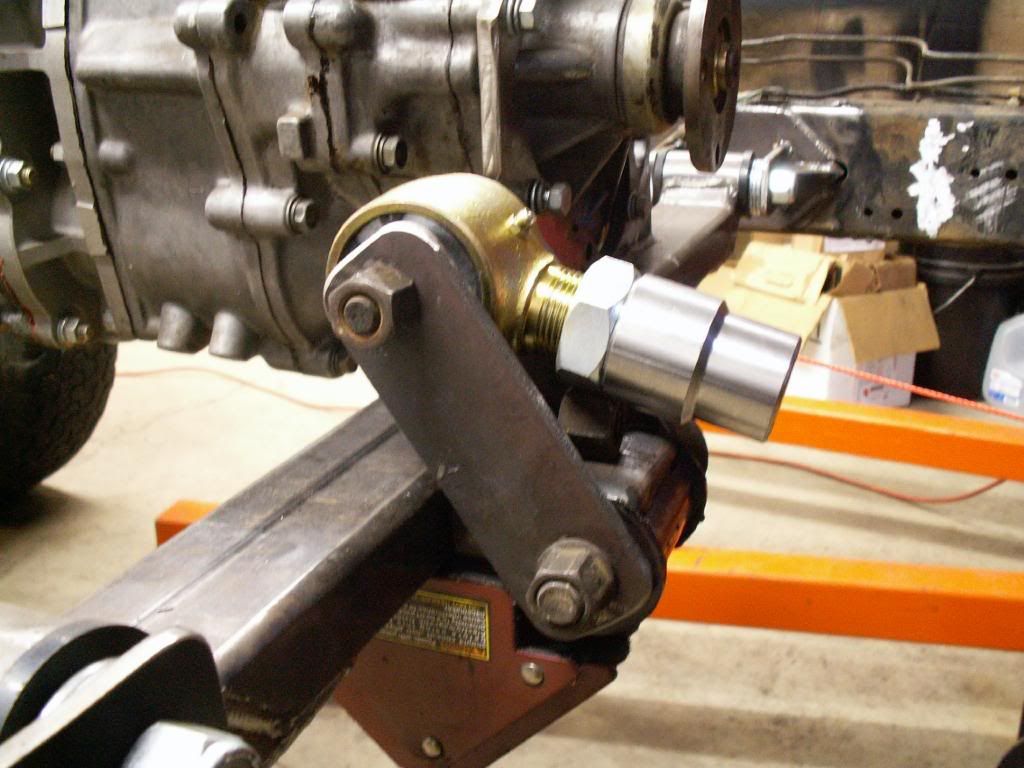

This is what I have been up to.

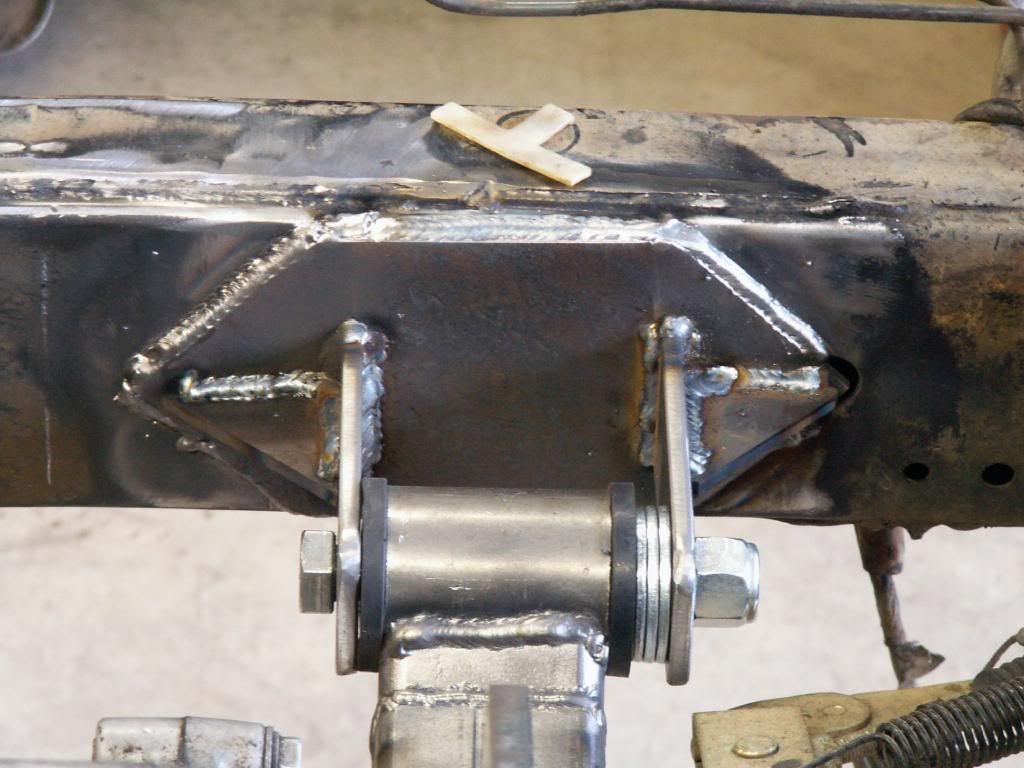

I capped the motor mounts.

This is the beginning of the next project for me. The old lady wants to ride along with the kids and the "Cooter" wasn't going to cut the mustard in that department. So out with the old and in with the new.

The plan so far; SAS the front, run the 22r with propane, rear leafs (hybrid mazda pack?), 39.5 Irocks on bead-locks, use the tube I bought for a int. cage, and most importantly MAKE IT AS LOW AS I CAN.

I plan on this being a trailer rig that will get beat into submission. Who knows, maybe it will turn into a buggy down the road like I originally wanted to build?

Nice and clean eh?

Stop looking at my *****...

Low-rider..............

I hope my neighbors are not trying to sell their house.

I want to let everyone know this right now, I will never do a SAS to a IFS truck AGAIN if the purpose is to make the most capable wheeler that I can.

This is a link to the reason why http://www.pirate4x4.com/forum/showthread.php?t=599542

P.S. Two wheel drive trucks have the same frame dimensions as a pre 86 4x4. Next time I will just convert a 2wd or start with a pre 86.

This is what I have been up to.

I capped the motor mounts.