You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Down and Dirty Transaxle Build

- Thread starter mtublazer2

- Start date

bgredjeep

Well-Known Member

- Joined

- Jul 1, 2011

- Messages

- 719

Aftermarket shifter for the AW4. Regular auto, or full manual control iirc.

Edit

Sorry, forgot which thread I was in when I replied. I presume they make one for this trans as well.

http://radesignsproducts.com/Home.php

Edit

Sorry, forgot which thread I was in when I replied. I presume they make one for this trans as well.

http://radesignsproducts.com/Home.php

zjtrey

Well-Known Member

rockwild said:what's a RAD shifter?

Theres lots of discussion on this on page 1 and 2

TURNEROFFROAD

Well-Known Member

Nice build going man!

zjtrey

Well-Known Member

Thanks for the compliments guys.. I really wanted to go to the crawl rally this weekend but teh youtoobs keep me motivated enough!

Been making lots of progress and not a whole lot of pics… I'm trying to make a harlan ride here in a few weeks and its looking pretty good for having it ready for shakedown.

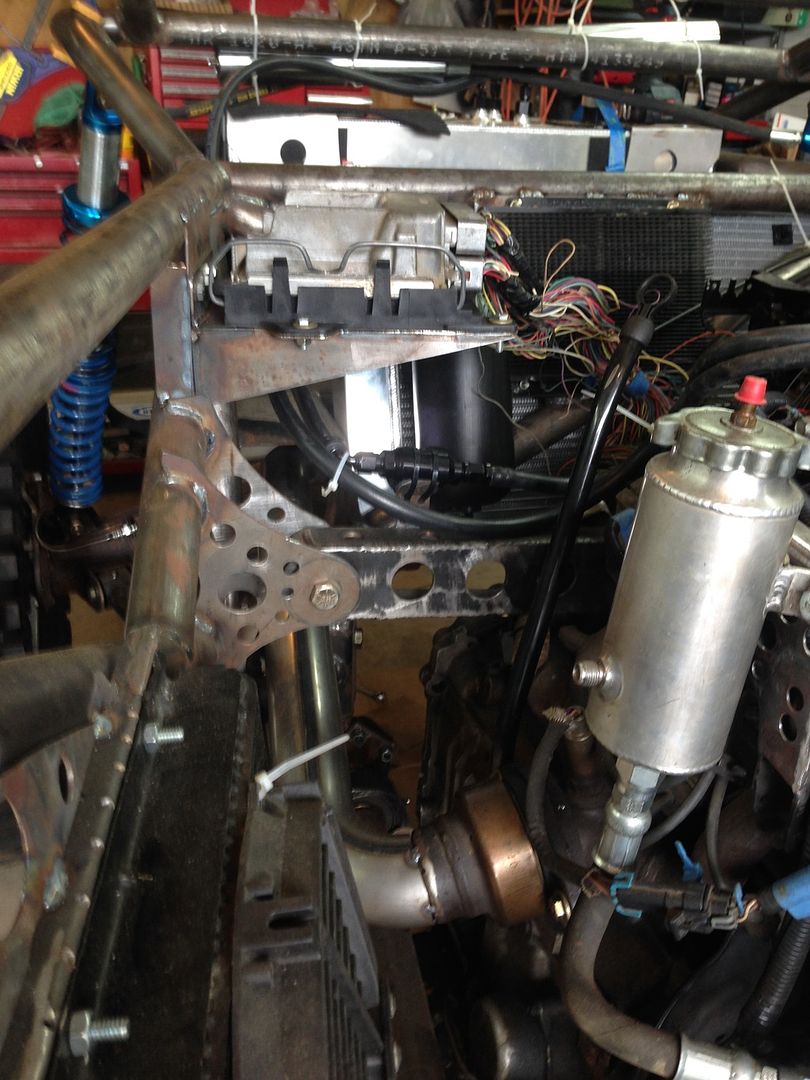

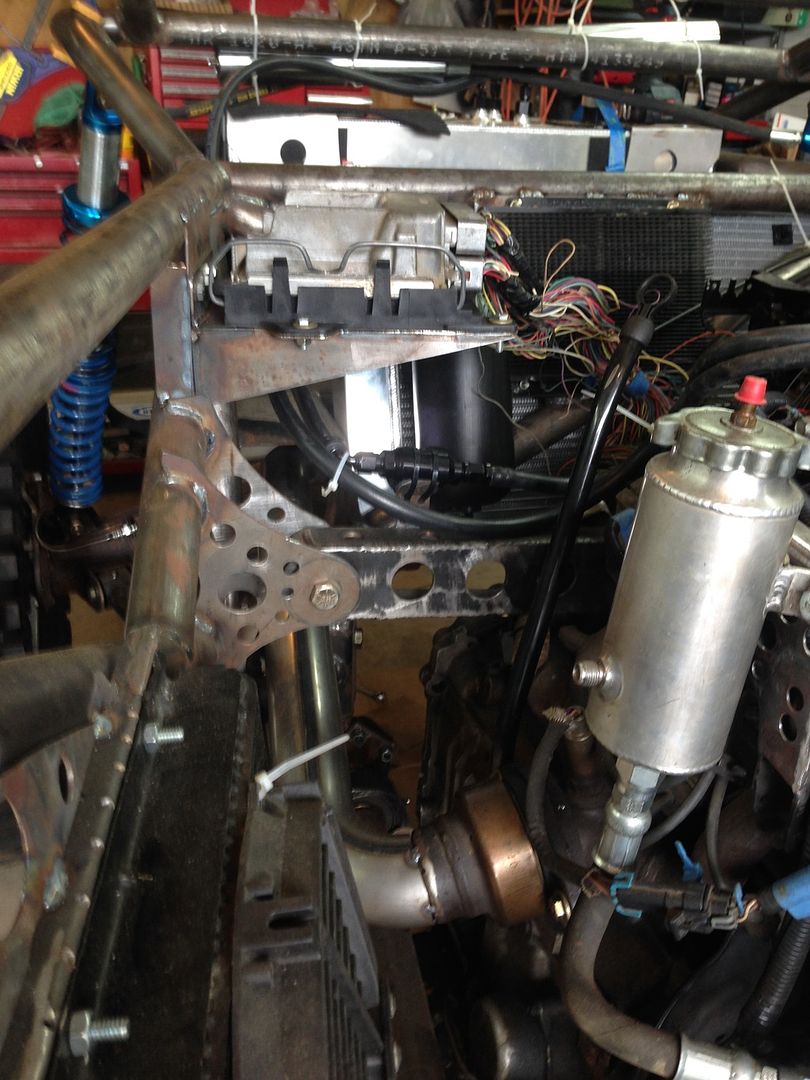

lower radiator mount…. and a chase way/ heat shielding for the exhaust

used some pucks for the upper rad mounts

trans cooler

PCM mounting

PCM mounting

rad plumbing

This is the connector for the lower rad hoses… i cut a hose barb from lowes in half to help with sealing and welded in a ? npt fitting so i can install the temp sending unit quickly.. i hope it works well there. if not i'll move it to the head later on.

A little firewall action before i start wiring its .125 aluminum

The only steel panels going on this thing… did this to protect myself and passengers from impalement lol..

one of my helpers

and slave labor haha

Been making lots of progress and not a whole lot of pics… I'm trying to make a harlan ride here in a few weeks and its looking pretty good for having it ready for shakedown.

lower radiator mount…. and a chase way/ heat shielding for the exhaust

used some pucks for the upper rad mounts

trans cooler

PCM mounting

PCM mounting

rad plumbing

This is the connector for the lower rad hoses… i cut a hose barb from lowes in half to help with sealing and welded in a ? npt fitting so i can install the temp sending unit quickly.. i hope it works well there. if not i'll move it to the head later on.

A little firewall action before i start wiring its .125 aluminum

The only steel panels going on this thing… did this to protect myself and passengers from impalement lol..

one of my helpers

and slave labor haha

mtublazer2

Well-Known Member

Good progress homie! 18 days and counting?

zjtrey

Well-Known Member

Thanks for the compliments guys!

I have a question… my brain is really wanting to tie the lower part of the shifter surround to the chassis bar below it here in the pic…

problem is theres a shifter cable, a bunch of wires, hydro lines ect really crowding the area… i think its possible to fit a tube in there but i'll have to re-route a few things to go on the outsides of the t case shifters instead of between them.

How important do you guys think this would be to overall chassis rigidity and longevity? i see a lot of buggies built without this even ultra 4 rigs just want to see what hardline says

I have a question… my brain is really wanting to tie the lower part of the shifter surround to the chassis bar below it here in the pic…

problem is theres a shifter cable, a bunch of wires, hydro lines ect really crowding the area… i think its possible to fit a tube in there but i'll have to re-route a few things to go on the outsides of the t case shifters instead of between them.

How important do you guys think this would be to overall chassis rigidity and longevity? i see a lot of buggies built without this even ultra 4 rigs just want to see what hardline says

sleepsontoilet

Well-Known Member

Apply direct force from it into the envisioned tube. If that tube doesn't spread the load through another multiple plane, it's a dead node and useless. Meaning if you aren't joining it into another tube junction rather just the middle of an unsupported tube, I would leave it as its just aesthetics at that point.

zjtrey

Well-Known Member

my intention is to tie into the node just below it where 3 tubes join in 3 different planes, I know the bar would add significant strength, but is it strength i really need is my question...

in my opinion running a vertical bar from that shifter surround point straight down wont help you much, that is unless you endo and take a direct hit to the center of the windshield bar. Your A-pillar plane is already fairly boxed. A diagonal brace if anything that would take away any legroom there. Your B pillar plane should have enough triangulation to keep the cage square.

Beerj

Sonzabitches!

Could you run 2 bars down at slight angles? Like "A" shaped? Not sure how much legroom you have and like others said, won't do much for strength but it might save you the hassle of rerouting hoses/wires

zjtrey

Well-Known Member

thanks for the input fellers… Im gonna leave it the way it is

zjtrey

Well-Known Member

been a while since I updated…

I sorta went into beast mode to get it ready for a shakedown run and quit taking so many pics ect..

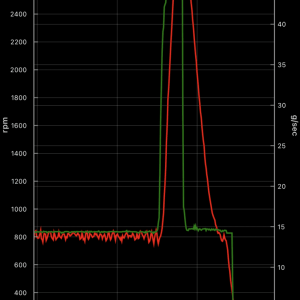

Nearing the end of wiring and prep to go riding this is what my brain felt like

and this is what my shop looked like

but got it running and driving a week or so before the trip and did some testing on our land.

time to get as many body panels on it as I can before harlan..

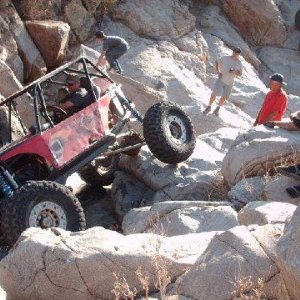

made it harlan a couple of weeks ago and I honestly couldn't be happier with this little ****er… had a few bugs come up like the throttle started getting sticky but a return spring fixed that and I'd adjusted my brake light switch a little too close to the pedal and the front brakes got real hot coming back to evarts from mason jar, again a simple adjustment and good to go.

was expecting a pretty dry weekend but the remnants of that tropical storm hit… here's a pic from the way home..

I sorta went into beast mode to get it ready for a shakedown run and quit taking so many pics ect..

Nearing the end of wiring and prep to go riding this is what my brain felt like

and this is what my shop looked like

but got it running and driving a week or so before the trip and did some testing on our land.

time to get as many body panels on it as I can before harlan..

made it harlan a couple of weeks ago and I honestly couldn't be happier with this little ****er… had a few bugs come up like the throttle started getting sticky but a return spring fixed that and I'd adjusted my brake light switch a little too close to the pedal and the front brakes got real hot coming back to evarts from mason jar, again a simple adjustment and good to go.

was expecting a pretty dry weekend but the remnants of that tropical storm hit… here's a pic from the way home..

zjtrey

Well-Known Member

some vids from the trip

https://youtu.be/AaAgTYtJwM4

https://www.youtube.com/watch?v=TpUgHRXYkF4

https://www.youtube.com/watch?v=RVz2UX7lGI4

someone help me with the embed?

There are also a few video's on Facebook that i can't figure out how to post here…

overall I'm very happy with the buggy, I think the chirping sound is idler pullies which have been changed out since i got back home..

the shocks were a bit stiff on the valving so i took some shims out over the weekend and its riding much better now.

having never been in something lightweight, the difference is night and day compared to my other buggy that weighs around 5k, this one hasn't been on the scales yet but it should be just over 3k, I know my tow rig knew the difference because the fuel needle didn't move nearly as fast lol..

The RAD shifter didn't work out, maybe i wired it wrong but i did my home work on it, all i get is a check engine light when i turn it on. it throws a code for each shift solenoid and TC lockup sol so that indicates to me that i got the correct wires.. still need to do more troubleshooting on that but the trans works great in normal operation. It holds first just fine when i want it to and it shifts quickly enough into second to not really need to lock it in.

I gave pony hill a real shot for the first time also, buggy walked right up to the great big hole about half way up.. it was the first day so I didn't beat on it much from there, i was ecstatic to get over the slab at the bottom haha..

https://youtu.be/AaAgTYtJwM4

https://www.youtube.com/watch?v=TpUgHRXYkF4

https://www.youtube.com/watch?v=RVz2UX7lGI4

someone help me with the embed?

There are also a few video's on Facebook that i can't figure out how to post here…

overall I'm very happy with the buggy, I think the chirping sound is idler pullies which have been changed out since i got back home..

the shocks were a bit stiff on the valving so i took some shims out over the weekend and its riding much better now.

having never been in something lightweight, the difference is night and day compared to my other buggy that weighs around 5k, this one hasn't been on the scales yet but it should be just over 3k, I know my tow rig knew the difference because the fuel needle didn't move nearly as fast lol..

The RAD shifter didn't work out, maybe i wired it wrong but i did my home work on it, all i get is a check engine light when i turn it on. it throws a code for each shift solenoid and TC lockup sol so that indicates to me that i got the correct wires.. still need to do more troubleshooting on that but the trans works great in normal operation. It holds first just fine when i want it to and it shifts quickly enough into second to not really need to lock it in.

I gave pony hill a real shot for the first time also, buggy walked right up to the great big hole about half way up.. it was the first day so I didn't beat on it much from there, i was ecstatic to get over the slab at the bottom haha..

sleepsontoilet

Well-Known Member

Plans to add.a boost gauge, and a smaller pulley?

zjtrey

Well-Known Member

thanks for the pics and videos simo!!

I have a smaller pulley I could put on but I wanted to shake everything down real good before i add power.. when the boost kicks in as is it feels really strong..

I have a smaller pulley I could put on but I wanted to shake everything down real good before i add power.. when the boost kicks in as is it feels really strong..

Eddyj

Well-Known Member

It turned out awesome. I really dig the unique look. In my mind a picture the finished buggy looking completely different, I like it. What's the belly height?

zjtrey

Well-Known Member

Thanks! Honestly, I didn't build it with looks in mind. I had a clear vision of what I wanted on the big picture level, light and tight with no wasted space or extra **** to get in the way haha. Im going to finish paneling the sides and make a cover for the engine bay with aluminum and use that area for a cooler and storage, I also plan to tear it down and paint it this fall.

Belly height is about 19" its a little lower in these pics because the springs settled just a little and i didn't adjust… I really liked being low makes the pucker factor stuff more enjoyable

Belly height is about 19" its a little lower in these pics because the springs settled just a little and i didn't adjust… I really liked being low makes the pucker factor stuff more enjoyable