Time for a long over due update.

the shop move is for the most part DONE!!!! It was painful at best. we still have some issue to get taken care of. We have to figure out where all the current machines are going to go and what machine we plan to have in the future will go. The they must be wired. The lights…well all but 3 are not working so I am going to spend a day changing ballast and adding more lights. and we still have to build a ramp to get rings in and out of the shop.

AS far as T-rex it was not easy to get it in the shop with out a ramp, with no brakes, the steering not being completely dialed in and the no engine power…pretty mush it was a really big, heavy roller.

So that was sketchy at best. Hopefully our ramp will be in very very soon. as soon as we got T-rex in (since it was the very last thing we moved in) we started work again. We cut out the tiny temporary axel, cut off all the old bracketry on the rear, and eliminated every bit of the rust . Clean fresh slate. First thing we added was a new crossmember built from .120 wall DOM and 1/8 plate to support the rear of the fuel tank and all the EVAP equipment that is required in these newer trucks.

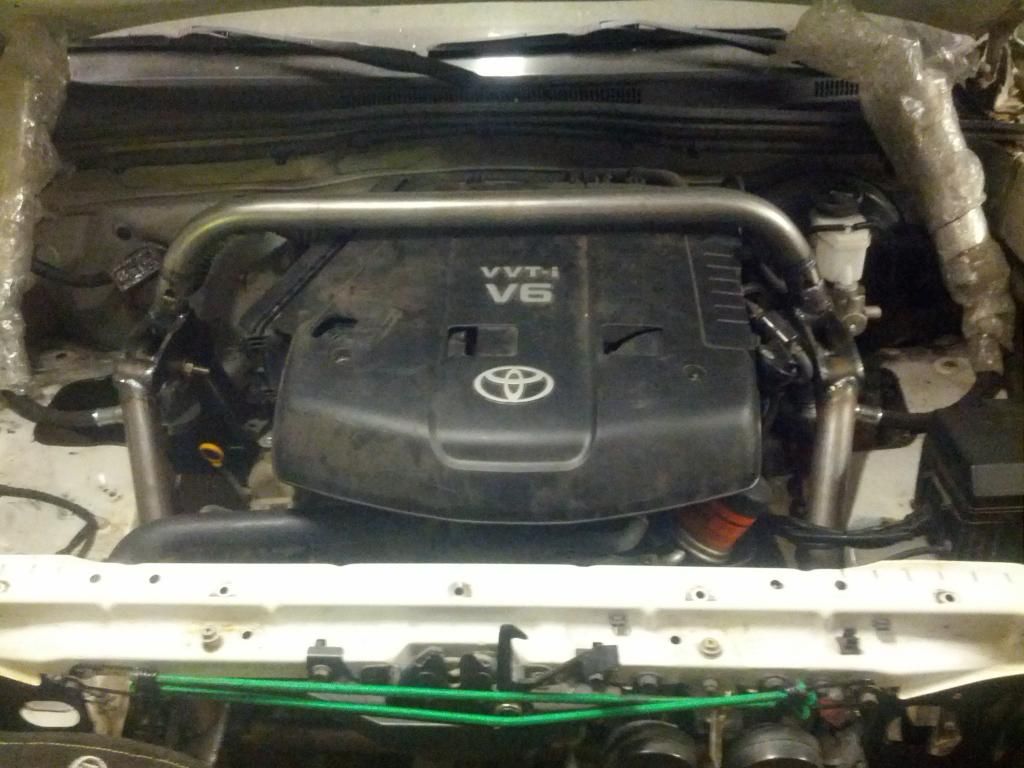

then the snorkel was modified to hook up to the aluminum air box we built earlier and miss the shock towers completely

we also gave T-rex some teeth. They look cool but they are mainly to reinforce the seem of what left of the original frame and the repair plate and fish plate up front. Two large teeth on the top row, toward the rear, on both sides have been added also but I failed to take a picture after that was done.

http://i1219.photobucket.com/albums/dd428/priest0321/IMG_0949_zps57fcbb43.jpg[/IMG]

Next we pulled the front axel out for final welding, assembly and paint. We haven't gotten that far yet but we are heading in that direction. the Trans/TC crossmember was pulled for finial welding, sanding and paint. All of those task are complete. During disassembly of the drive train we found a rattling in the rear case…turns out the "stop foot" on the high low rail had snapped off and was casing sloppy shifting and engagement. the part has been ordered and should be here mid week. We'll up date you on that when we get the part and do the repair.

The rear axel was also se and we have the lower links in place and the up link's brackets mounted. We wanted to have the exact same link measurements in the rear as we had up front for simplicity and while this worked for the lower links it did not for the upper link.

these last two pictures are a little shop tour. though it looks like a bomb went off these were taken about a several days ago and I assure you the shop looks much mooch more organized now. Pay attention to the shop back ground pictures from here on out and you will see some interesting builds. We have the very first East Coast Bomber chassis that will be coming in this week from Bomber Fab. we will be putting together chassis for Randy.

We also have two custom chassis that will be built in house in the very near future. Both designed and built by Dynamite Design. One is a two seater Ultra 4 with plans to be at KOH this coming year. The other is a larger four seat version of out new chassis that will be built for a hard core trail rig.

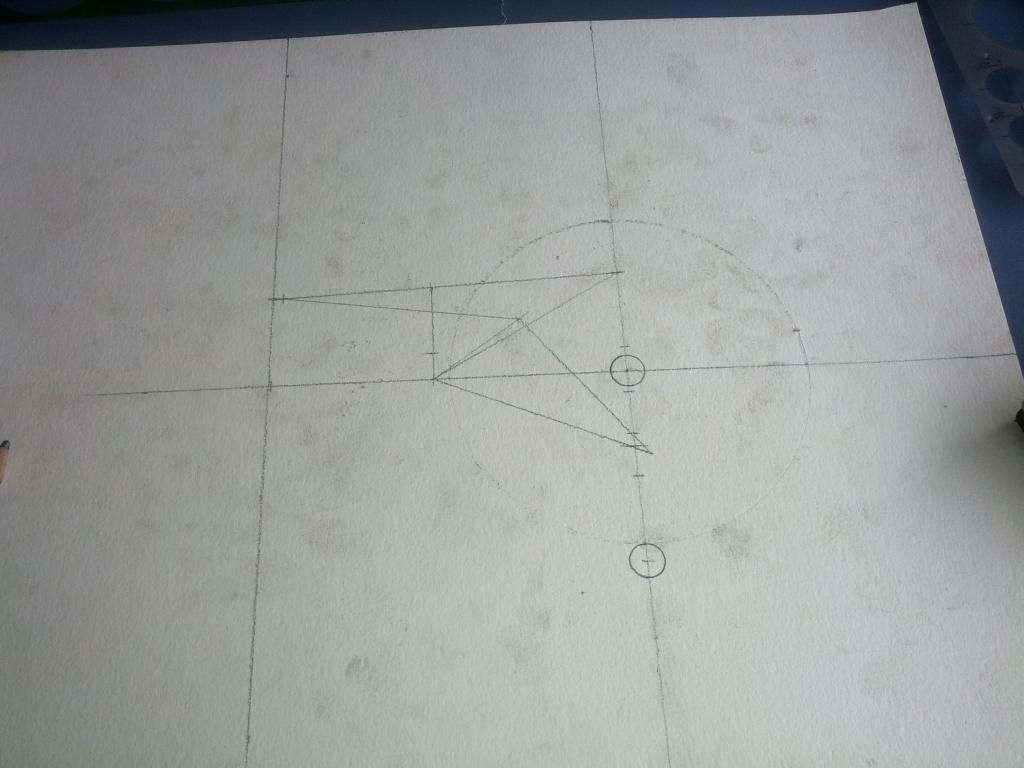

Next on the list is to finish the rear 3 link. then we are in a little bit of a holding pattern. The next major project is the cantilever set up. the way we designed it, the just a lot of stuff getting framed into a tiny space. So until all the parts get here we have elected to wait on that part. we want to ensure that the link don't interfere with the cantilevers, and that the sway bar doesn't mess with either one of them and the air bump are in the right place as well. needless to say a lot of stuff hitting the axel and running out of real estate really really fast.

The kinks are working their way out.

The kinks are working their way out.