Here’s the story: 1983 Ford Ranger 2.3L engine, unknown mileage, but the truck was parked ~15 years ago. I pulled the motor last fall to swap into my flat fender, and am finally getting around to test firing the engine before I dive into final wiring/plumbing/etc. I have replaced the plugs, cap, rotor, and wires. It uses the Duraspark II ignition setup, and I’ve got a new a new module/brain box and coil. My initial attempt at getting it to fire revealed a stripped timing belt, so using the string method I reset crank/cam/dizzy timing. Now with the timing set, I still can’t get the motor to fire up and run on its own? It will cough and sputter through a couple revolutions, but will not take off and run… I have tried both starting fluid and straight fuel into the carb with no better luck. I do know the carb needs rebuilt, as I can’t get any fuel to squirt into the venturi even though the fuel bowl is full…. My gut tells me it is still a timing issue, but I would think even a few degrees off and it should still fire and run, albeit poorly? Anyone have any solid tips on starting from scratch on a 2.3L Ford in terms of initial timing setup, and initial starting?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ford 2.3L Won't Run???

- Thread starter tobyw

- Start date

hlb3

Zombie Hunter

You might try PMing Fordzuki on here, he swapped a 2.3 into his LJ, so he might have some tips for you.

zukkev

Cornfuzzled yet again...

What is this 'string' method you mention???

...Ford 2.3L are quite simple. Line up the timing marks for cam/crank, along with lining up the distributor drive t-belt pulley to it's mark...making sure you are on #1TDC compression stroke of course...drop the distributor in to #1...

...Ford 2.3L are quite simple. Line up the timing marks for cam/crank, along with lining up the distributor drive t-belt pulley to it's mark...making sure you are on #1TDC compression stroke of course...drop the distributor in to #1...

What is this 'string' method you mention???

...Ford 2.3L are quite simple. Line up the timing marks for cam/crank, along with lining up the distributor drive t-belt pulley to it's mark...making sure you are on #1TDC compression stroke of course...drop the distributor in to #1...

Unfortunately, the front plastic is all gone on this engine so the factory alignment marks aren't present... The string method consists of the following, from what I've read on the interwebs:

1.) Crank at #1 TDC compression

2.) Aux shaft rotated such that the dizzy rotor is pointing directly at #1 post on cap

3.) Run a string from the centerline of the cam pulley bolt to the centerline of the Aux pulley bolt

4.) Rotate the cam pulley so that the timing pointer on the pulley is directly in line with the string

5.) Install the timing belt and rotate the engine 2 full revolutions, take slack out of timing belt, and ensure the cam pointer still lines up perfectly with the string between bolt centerlines

Supposedly, this sets timing dead nuts 0*... I've done it 3 times, just to make sure.

It'll sputter, but won't light off and run. I have rotated the distributor both directions several degrees, and it just won't run on it's own

Zoediak

Well-Known Member

so this thing has been sitting for ~15 years since it last run, correct?

and you are still using the same carb that was on it then?

I would suggest two things...

- since you are 'pretty sure' your timing is correct, if you have not done any type of compression check I would do that now to see where things are at.

- pull that carb off and get it cleaned out and working properly. If fuel has sat in it for that long, I would bet there are some air ports and fuel ports plugged up/varnished over.

fuel/air/spark/compression are the basics needed... start checking at the easy stuff and eliminating them one by one. with an OLD carb, I would bet there could be a problem there as well... even dumping fuel down it won't always help if it isn't getting the proper air mix as well..

just a couple of thoughts... I'm old, and I probably don't remember how to get an engine running anymore myself.. :haha: so take it for what it's worth.

and you are still using the same carb that was on it then?

I would suggest two things...

- since you are 'pretty sure' your timing is correct, if you have not done any type of compression check I would do that now to see where things are at.

- pull that carb off and get it cleaned out and working properly. If fuel has sat in it for that long, I would bet there are some air ports and fuel ports plugged up/varnished over.

fuel/air/spark/compression are the basics needed... start checking at the easy stuff and eliminating them one by one. with an OLD carb, I would bet there could be a problem there as well... even dumping fuel down it won't always help if it isn't getting the proper air mix as well..

just a couple of thoughts... I'm old, and I probably don't remember how to get an engine running anymore myself.. :haha: so take it for what it's worth.

I do know the carb needs rebuilt, as I can’t get any fuel to squirt into the venturi even though the fuel bowl is full….

so this thing has been sitting for ~15 years since it last run, correct?

and you are still using the same carb that was on it then?

I would suggest two things...

- since you are 'pretty sure' your timing is correct, if you have not done any type of compression check I would do that now to see where things are at.

- pull that carb off and get it cleaned out and working properly. If fuel has sat in it for that long, I would bet there are some air ports and fuel ports plugged up/varnished over.

fuel/air/spark/compression are the basics needed... start checking at the easy stuff and eliminating them one by one. with an OLD carb, I would bet there could be a problem there as well... even dumping fuel down it won't always help if it isn't getting the proper air mix as well..

just a couple of thoughts... I'm old, and I probably don't remember how to get an engine running anymore myself.. :haha: so take it for what it's worth.

I should have been more specific... the carb needs rebuilt again. I say again because I just rebuilt it last weekend, after tearing it down and letting it set in Berryman Chem-Dip for an hour and blowing out all of the ports with compressed air. New accelerator pump and new enrichment valve actuator (both diaphragm type rubber components) were included with the rebuild kid, along with the needle and seat. I cleaned up all of the jets/nozzles that were disassembled and blew out all of the passages, and took a brass wire brush to the fuel bowl itself to clean up the nasty varnish that was still clinging to the corners and such. Thought I did a pretty fair job, but apparnetly not... Regardless, I would still expect it to run for a spell with a little fuel and/or starting fluid directly in the carb throat??

I have thought about a compression check, but how much would it really tell me at this point since there is no heat in the block to help things expand and seal? I always thought you were supposed to do a compression check with it at or near operating temp, otherwise it was useless info? I know each hole produces *some* compression, as I can feel it against my thumb when I cover the plug hole and spin it by hand... Again, not at all discounting the idea, I'm open to ANYTHING that will help get it fired up, so thank you for your time in responding for sure!!!

Jacob

Viewer Discretion Advised

My bet is you missed/messed something up with the timing or the carb rebuild. But I only do this mechanic stuff on the internet part time.

***update*** it runs!!!

SUCCESS!!! Sort of...

After stripping out all of my temporary wiring and starting over using the Duraspark wiring diagram found here, I was able to get it to fire up and run for a good 20 seconds on a couple squirts of starting fluid! That's good enough for me right now, at least to assure me that the motor can/will run. However... Another issue has popped up. I went through (3) starter solenoids trying to get it to fire last night?? For some reason, I'm burning them out to where they will no longer click and send juice to the starter motor... I can jump between the "i" and "s" terminals, either with a screwdriver or a remote start button, and nothing... Verified it all with a test light, and no juice is passing through the solenoid. Burnt up (3) of them in a matter of about 15 minutes, with a total of maybe 3 turns of the key on each one?! One thing I found that concerns me is that I've got continuity between engine ground and the starter B+ terminal? I don't really know how or why, wiring isn't my strong suit at all, but I would think the B+ lug would be isolated from the rest of the starter body that is grounded via the bellhousing etc.???

Long story short, now I know the timing thing is handled but I'm stumped on simple wiring?! Thanks for any further help!!!

SUCCESS!!! Sort of...

After stripping out all of my temporary wiring and starting over using the Duraspark wiring diagram found here, I was able to get it to fire up and run for a good 20 seconds on a couple squirts of starting fluid! That's good enough for me right now, at least to assure me that the motor can/will run. However... Another issue has popped up. I went through (3) starter solenoids trying to get it to fire last night?? For some reason, I'm burning them out to where they will no longer click and send juice to the starter motor... I can jump between the "i" and "s" terminals, either with a screwdriver or a remote start button, and nothing... Verified it all with a test light, and no juice is passing through the solenoid. Burnt up (3) of them in a matter of about 15 minutes, with a total of maybe 3 turns of the key on each one?! One thing I found that concerns me is that I've got continuity between engine ground and the starter B+ terminal? I don't really know how or why, wiring isn't my strong suit at all, but I would think the B+ lug would be isolated from the rest of the starter body that is grounded via the bellhousing etc.???

Long story short, now I know the timing thing is handled but I'm stumped on simple wiring?! Thanks for any further help!!!

One thing I found that concerns me is that I've got continuity between engine ground and the starter B+ terminal? I don't really know how or why, wiring isn't my strong suit at all, but I would think the B+ lug would be isolated from the rest of the starter body that is grounded via the bellhousing etc.???

Its damn near a direct short. Starter motors are HUGE current draws, so to get that kind of current out of a 12v battery, your resistance is going to be next to nothing. Power into the B+, thru the limited amount of copper windings, and then those windings finally go to ground via the starter case. So yes, you will get continuity.

A locked/stalled starter motor can reach upwards of 300 amps. Its possible the motor is a little tight, or you held the starter too long while trying to make the motor run. Could be cheap starter relays too. not sure what your using.

Do you have a clamp on style amp meter? That would tell you real quick what your drawing.

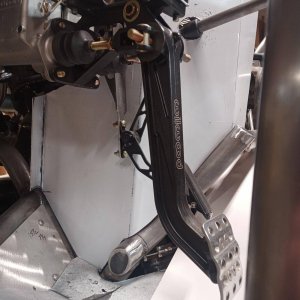

Traced it down to a lack of body ground... The solenoid is firewall mounted, and body is sitting on rubber pucks. In my haste, I had forgotten to run a ground strap from the head to the firewall :looser: $35 for another solenoid and a new ground strap, and the ignition systems works great!

Now having issues with the damn Holley 5200 not wanting to idle, at all... Almost acts like there is no vacuum getting through the carb to draw fuel, so I'm tearing it back apart to make sure there isn't a gasket overlapping a hole or something along those lines.

Now having issues with the damn Holley 5200 not wanting to idle, at all... Almost acts like there is no vacuum getting through the carb to draw fuel, so I'm tearing it back apart to make sure there isn't a gasket overlapping a hole or something along those lines.

Seems to be a common problem lately. Its been hitting a lot of the fuel injected bronco guys. Bad/old grounds between all the body parts are really messing with the computers.

Ideally you want a nice ground between your battery and your ALT case, another good one between body and engine, and body and frame.

You've got rubber body bushings, but also dont forget your rubber engine mounts too. Lots of isolation between major compenents.

Ideally you want a nice ground between your battery and your ALT case, another good one between body and engine, and body and frame.

You've got rubber body bushings, but also dont forget your rubber engine mounts too. Lots of isolation between major compenents.

skinny_pedal

Well-Known Member

OHMS Law, not only a good thing it's the LAW!