-

Help Support Hardline Crawlers :

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

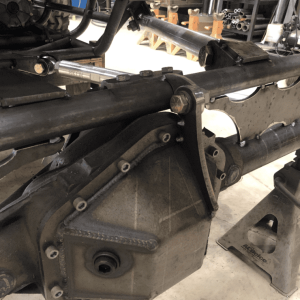

Ford high pinion dana44 with cast wedges

- Thread starter Brad597

- Start date

Won't there be part of the tube itself missing?

They say the only way to fix it, is to retube it. (Just what I've read)

If I gouge them off would that leave it too thin, and be weak?

I'm sorry for all the questions on this, just trying to figure it out.

The only brackets I will be using is control arm brackets for a long arm kit, and coilover mounts.

Again sorry for the dumb questions.

They say the only way to fix it, is to retube it. (Just what I've read)

If I gouge them off would that leave it too thin, and be weak?

I'm sorry for all the questions on this, just trying to figure it out.

The only brackets I will be using is control arm brackets for a long arm kit, and coilover mounts.

Again sorry for the dumb questions.

UABYJ94

Well-Known Member

If you are looking to put the coil spring pads where the wedges are then just cut the top of the wedge flat to the point you can weld the plate to it. You will only be another 1/4" higher at most by doing that rather than trying to cut the whole thing off. You should still be able to get tabs welded from the plate to the wedge area under the plate or to the axle tube itself. I've seen a few guys around here running it that way.

5BrothersFabrication

Zzzzz....

Sounds like you have a full size Bronco axle, go buy a truck axle. They have wedges that are just welded across the top and bottom. Then you can take a cutoff wheel... Wait, about 5 cutoff wheels, and just cut behind the welds and hammer them off. Then just flapwheel the welds down. I've done it, maybe had 4 hours in the whole job.

viseashane1

Well-Known Member

77 and old 44 will just cut off

fordcontraption01

Well-Known Member

yes sir you are correct.viseashane1 said:77 and old 44 will just cut off