crash2

-Oh no I picked a side-

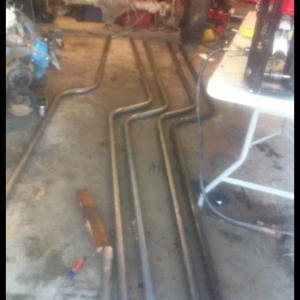

My process for doing a chassis--and one I have a number times(and seems to work for me). I always start at the skip plate. Start by figuring the width of the chassis and then lower link placement on the chassis. Once I get that figured out I rough in the side plates. My next step is to build the lower links. Once thats done I now have the length of my uppers since I like to run equal length links. So once I have the upper lengths I can figure out the multiple location holes for the uppers. Since this is my first MOA I wanted some diversity on the upper placement for squat/anti squat numbers--unlike on my shafty's where I have those geometry's figured out for my driving style.