brokenparts

Well-Known Member

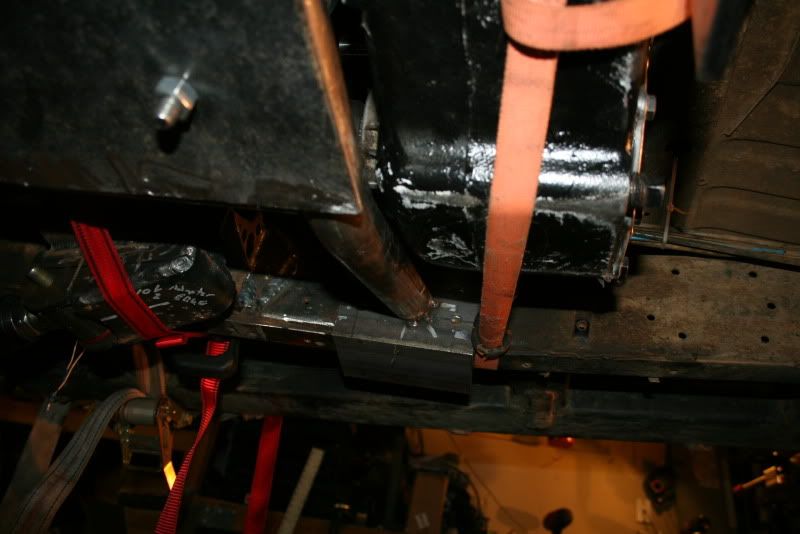

made a plate to mount the Hydroboost in the stock location:

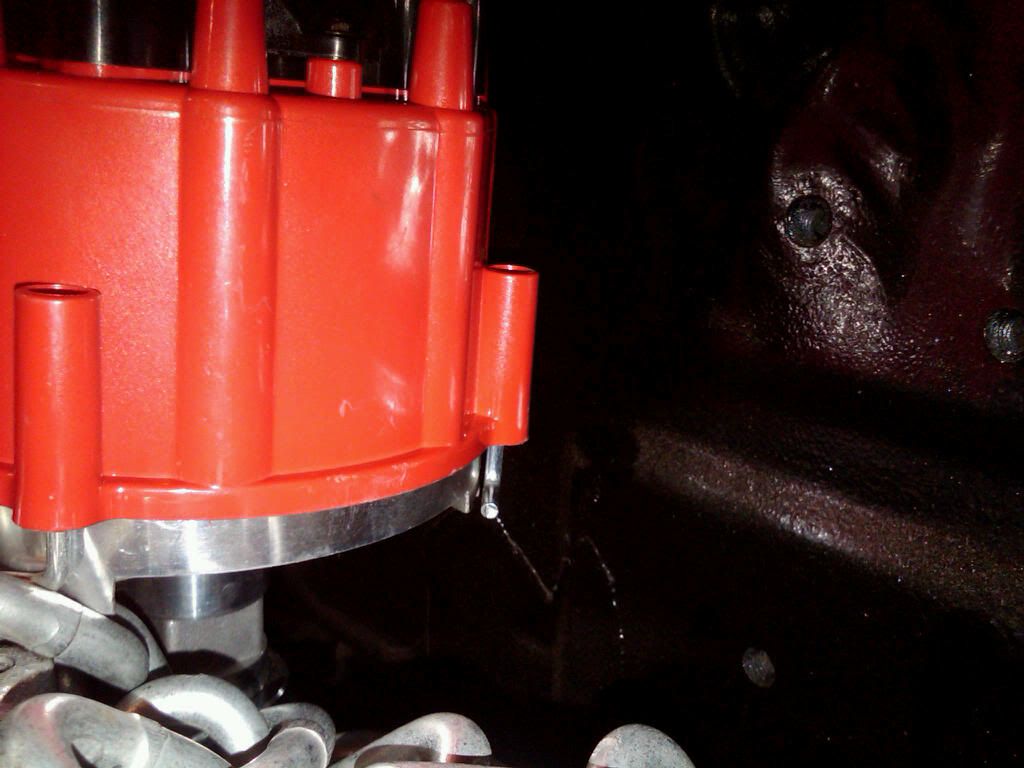

then I pulled the column to mount the orbital directly to the firewall so I woulnt have issues with the body flexing with the orbital mounted to the frame. The bonus is that I dont have to redo any of the wiring:

with a little luck I should be able to get it all plumbed and move onto building the crossmemebers.

then I pulled the column to mount the orbital directly to the firewall so I woulnt have issues with the body flexing with the orbital mounted to the frame. The bonus is that I dont have to redo any of the wiring:

with a little luck I should be able to get it all plumbed and move onto building the crossmemebers.