couple questions for those who are following still... While the front axle has been pulled I went ahead and inspected the wheel bearings, seals, etc. Everything looked decent but I decided to replace the spindle needle bearings in favor of the Longfield nylon bushings.

http://www.longfieldsuperaxles.com/products/New-Dana-60-&-44-Spindle-Bushings.html

It looks like it replaces most of the seals but I wondering which ones I'll still need. I posted something in the vendor section but havent seen anything posted back yet. Which seals out of the the "spindle kit" do I still need to use after installing bobby's bushings?

and still run these right?

Next question is about transmission coolers/lines/fittings... I hate figuring out fittings. I have this cooler in -8an with the temp switch also in -8an:

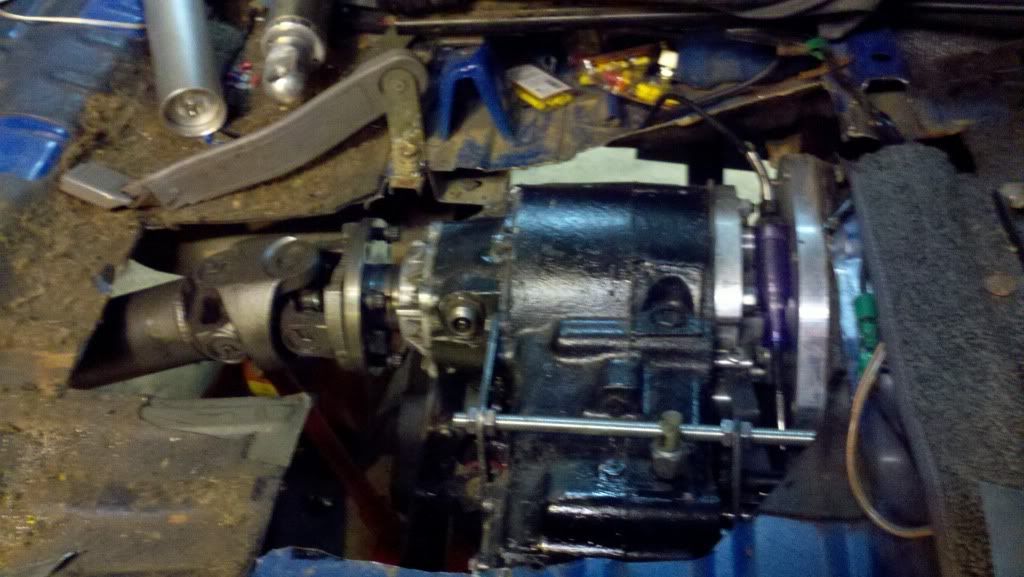

The cooler fan came with 8an to 1/2 barb fittings which I believe are for 1/2 rubber lines. My th400 is currently set up for hard lines from the housing (I'm pretty sure they are female 5/16ths). I also have 12 feet of 1/2" rubber tranny line already but I could be easily persuaded to use something else for ease of installation. I also need to get my fan switch and tranny temp gauge plumbed in as well.

I think the easiest way to go is just to use the rubber line but I'm having a hell of a time trying to find a fitting that will convert from the 5/16 fitting (that makes the hard line 3/8ths right?) out of the th400 to the rubber 1/2" hose. Anyone know if such a fitting exists? I know I could probably do it with a series of adapters but I would like to try to avoid that.

Other than that (just had a baby boy so the project has been put on the back back burner)... I've managed to press in some longer wheel studs, repack some wheel bearings, and clean up the front housing a bit. I thought it was tough to get out to the garage before... now I literally have to sneak out there in the middle of the night to get anything done. I swear I could have this thing back on the road if I had 2 or 3 solid weekends of wrenching with no distractions. Maybe I should send the family on vacation without me.