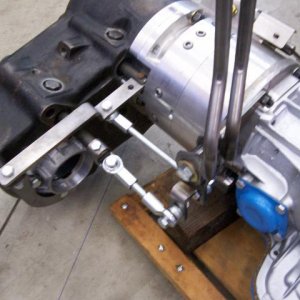

So, I have my rig for the most part figured out. The chassis is sitting on a table, engine, trans, t-case mounted, radiator will sit in place. The suspension is all in place. I just have 2 tires on the rig and suspension full flex so that I can allow for tire clearance and room for shocks during the build.

I have chosen a shock company and they are ready to build but they want me to provide unsprung corner weights so they can valve accordingly. That's where I'm a little confused. I have an engine hoist and ordered a 660lb digital meat/game/luggage scale off Amazon. It was cheap, maybe a mistake. But If I grab any corner of the rig, I'm really picking up more than the weight of just that corner. The chassis is just going to pivot diagonally on the table.

I have a chart with engine weight, trans, t-case, all the tube. I can guestimate my total weight, I can throw a floor jack on either side of the lower chassis and get a balance point. Then I can get a weight balance, %, or whatever you want to call it, but I still don't have an actual corner weight.

If I put all the tires on it and let the frame drop down and rest on the links, if I lift one front corner I fell like I'm really picking up half the vehicle, not just one corner.

How do you think I can get some kind of accurate number? The shock guys don't charge to valve for me, but have to build something and are willing to start me off in the ballpark. I would like to provide some kind of accurate number. I know the shocks aren't going to be perfect/magic from the get go. Might as well order the spanner wrench with the shocks for future changes.

I'm guessing my complete chassis would be between 1750 and 2000 lbs complete, then somewhere in that range for axles and tires.

The internet said I should drive up on a bathroom scale? Build a fulcrum arm, result is a ratio. Should I go buy 4 scales instead?

What did you do?

Thanks!!

I have chosen a shock company and they are ready to build but they want me to provide unsprung corner weights so they can valve accordingly. That's where I'm a little confused. I have an engine hoist and ordered a 660lb digital meat/game/luggage scale off Amazon. It was cheap, maybe a mistake. But If I grab any corner of the rig, I'm really picking up more than the weight of just that corner. The chassis is just going to pivot diagonally on the table.

I have a chart with engine weight, trans, t-case, all the tube. I can guestimate my total weight, I can throw a floor jack on either side of the lower chassis and get a balance point. Then I can get a weight balance, %, or whatever you want to call it, but I still don't have an actual corner weight.

If I put all the tires on it and let the frame drop down and rest on the links, if I lift one front corner I fell like I'm really picking up half the vehicle, not just one corner.

How do you think I can get some kind of accurate number? The shock guys don't charge to valve for me, but have to build something and are willing to start me off in the ballpark. I would like to provide some kind of accurate number. I know the shocks aren't going to be perfect/magic from the get go. Might as well order the spanner wrench with the shocks for future changes.

I'm guessing my complete chassis would be between 1750 and 2000 lbs complete, then somewhere in that range for axles and tires.

The internet said I should drive up on a bathroom scale? Build a fulcrum arm, result is a ratio. Should I go buy 4 scales instead?

What did you do?

Thanks!!