You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Low Budget rear engine, 37"s

- Thread starter RustyC

- Start date

Eddyj

Well-Known Member

You need to chill, bro.

your making the rest of us lazy.

you going to throw a quick coat of paint on it next?!?

your making the rest of us lazy.

you going to throw a quick coat of paint on it next?!?

Last edited:

Eddyj

Well-Known Member

Stupid question: can you get the cap off with ram on?

RustyC

Well-Known Member

- Joined

- Dec 15, 2010

- Messages

- 1,251

Yes. It is tight but clears.Stupid question: can you get the cap off with ram on?

RustyC

Well-Known Member

- Joined

- Dec 15, 2010

- Messages

- 1,251

For brakes I wanted to reuse the 99 E350 rear rotors and GM 3/4 ton calipers. The pilot of the rotors was opened up to fit over a 99-04 unit bearings I was running and fit the 05 unit bearings the same. Bearing was drilled 8-6.5" pattern.

I did have to grind the knuckle and caliper to fit but very, very little. Casting joint ridges mostly.

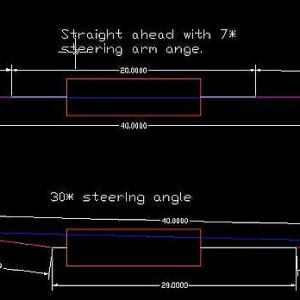

Cut out a couple of tabs and bolted it all together. 16" with 3 3/4" backspace wheels mounted in one of the pictures. It's all back together and works well. Happy with the little bit of steering angle I gained too.

I did have to grind the knuckle and caliper to fit but very, very little. Casting joint ridges mostly.

Cut out a couple of tabs and bolted it all together. 16" with 3 3/4" backspace wheels mounted in one of the pictures. It's all back together and works well. Happy with the little bit of steering angle I gained too.

TBItoy

Well-Known Member

if those tabs loosen up that caliper is gonna **** a little and **** up the wheel or drag on the rotor.

Eddyj

Well-Known Member

I was getting ready to post that also...

Maybe there something that were not seen in the pictures but it does look like the lead tab could be pulled down and the following tab could be pushed up. Causing a major cocking situation.

Maybe there something that were not seen in the pictures but it does look like the lead tab could be pulled down and the following tab could be pushed up. Causing a major cocking situation.

RustyC

Well-Known Member

- Joined

- Dec 15, 2010

- Messages

- 1,251

Gotta use red. None of the other inks will hold. No tac tac tac **** either! You have to whip it!What kind of wire are you using?....that'll never hold.

Buggy is coming along great, man! Keep it up

Eddyj

Well-Known Member

Can we get some internet welding experts in here ASAP!

I'm pretty sure you have to walk the cup not hostess cupcake loopy de loops and you will definitely have to back purge!

I'm pretty sure you have to walk the cup not hostess cupcake loopy de loops and you will definitely have to back purge!

GrandpaGary

New Member

- Joined

- Mar 13, 2021

- Messages

- 3

The best help!