Naughty_Finger

Well-Known Member

- Joined

- Dec 15, 2013

- Messages

- 65

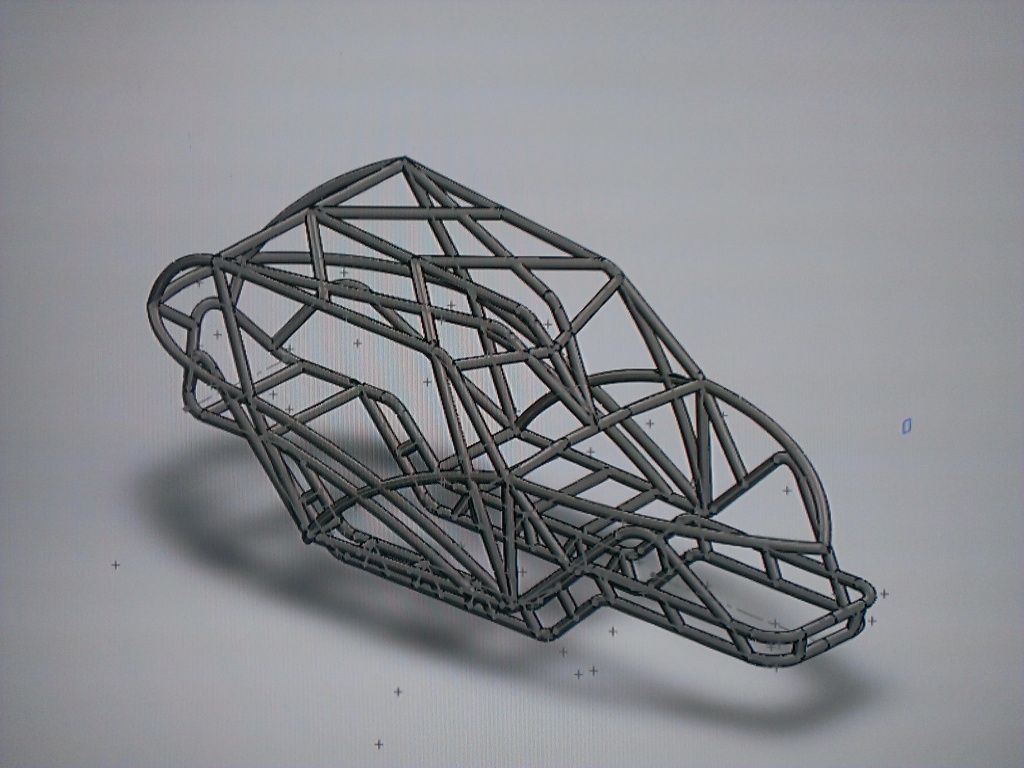

I have created and uploaded my first video showing how I am using Bend Tech Pro to design my tube chassis. Before anyone watches it, understand that I am not a professional fabricator. I have some abilities and some experience but I don't do this for a living. I also want to make it clear that this is only the first video. This video doesn't really highlight the best features of Bend Tech Pro which I will show later on when I start constructing the chassis. Bend Tech pro has a lot of great features when it comes to measuring for bends and notching tube. Since it calibrates to your specific tools it can save you a ton of money is screw ups. From a designing stand point it's pretty lacking but their are ways to overcome the issues. It might look like I am bashing the program in this first video but that's only because I'm using it for something it really shouldn't be used for. Before I bought the program I saw the promotional videos showing how "easy" it was to design a simple tube buggy. That's very misleading because if you watch that video the person making it knows EXACTLY where to place each point and how long everything needs to be. The chassis was either pre-designed or designed using some other software because in the real world it's not until you see the actual project coming together in front of you do you really get an idea of sizes, spacing and all that other fun stuff. It's the adjusting part that is the most difficult. I've redone this part in the video maybe 10 times and each time when I go to change a frame rail for instance, I have to delete it, move each individual point then remake the part. THEN delete the frame rail on the opposite side and all the points THEN paste the new one. THEN adjust everything connected to it. Adding 6 additional inches to my belly pan was a 30 minute endeavor. If it didn't have these "glitches" it would be a LOT easier to work with. If I were to make a single suggestion that would make this program much easier to design with , it would be to make it so that it functions like photoshop in that you can create groups or folders to place parts in that way you can manage the project much easier. As this thing gets bigger and more "complete" it's going to be a convoluted mess of points and parts with no ability to group them or name them. Here is the link to the video.

Bend Tech Pro Buggy Design Step 1

Bend Tech Pro Buggy Design Step 1