TealJ VL

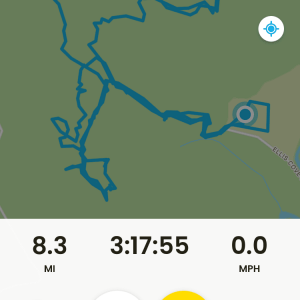

Work Sucks, I'm going Wheelin. Who's goin with me?

AAAAAGGGHHHH who's on first again I'm confused  but wait till you get that building....

but wait till you get that building....  mmmmmm heat

mmmmmm heat  GOOD LIGHT

GOOD LIGHT  No sunlight through the walls 8)

No sunlight through the walls 8)

but wait till you get that building....

but wait till you get that building....  mmmmmm heat

mmmmmm heat  GOOD LIGHT

GOOD LIGHT

hope you are getting a camera for Christmas!

hope you are getting a camera for Christmas!

and kelly I can agree I can't wait till it out and on the trails... this vehicle has been down for 2yrs. for me, but it will be worth the wait.

and kelly I can agree I can't wait till it out and on the trails... this vehicle has been down for 2yrs. for me, but it will be worth the wait.