tomsbrokeagain

Well-Known Member

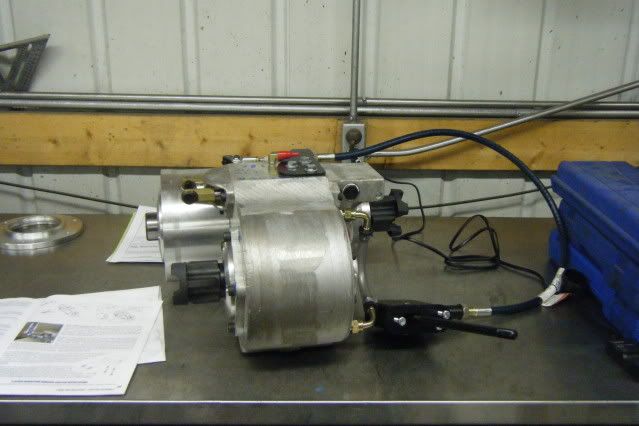

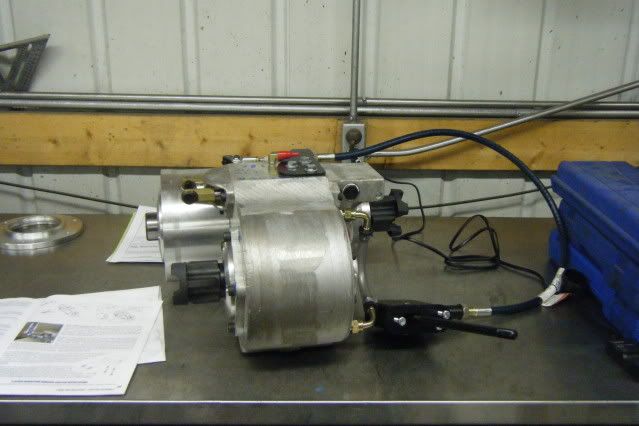

The pictures should speak for themselves!

Now to remove this heavy pig. The whole skid is 3/8 plate:redneck:

Remove old T-case

Installing new T-case

Now back out to work on the crossmember:redneck:

Now to remove this heavy pig. The whole skid is 3/8 plate:redneck:

Remove old T-case

Installing new T-case

Now back out to work on the crossmember:redneck:

![IMG_5496[1].jpg](http://attachments.www.hardlinecrawlers.com/xfmg/thumbnail/23/23128-3a187c4f83f872c0fcfd76a6776f08ca.jpg?1652262351)