Wildman1

Well-Known Member

I need to make some more space under the front of my Jeep. Currently I have the Hydro-assist ram attached to the diff cover on the swapped in HP44 axle. The axle is Waggy width. So I am woundering if I can move the hydro cylinder to attach on the pass side. But to do so I would have to put the cylinder parallel with the lower edge of the axle tube. I know I could build a skid for the cylinder but what about the shaft?

I am wanting to do this because I need a suckdown winch on the front. I have been toying with making a bracket to mount the winch to the axle tube. And if I don't then I need to mount it under the front of the Jeep some where.

So ideas, comments, suggestions?

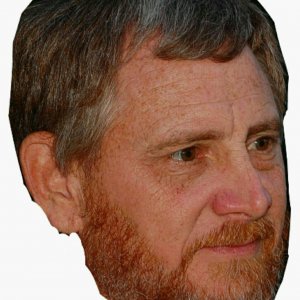

Here is what it looks like now.

I am wanting to do this because I need a suckdown winch on the front. I have been toying with making a bracket to mount the winch to the axle tube. And if I don't then I need to mount it under the front of the Jeep some where.

So ideas, comments, suggestions?

Here is what it looks like now.