chrissybf86

Well-Known Member

ill work 4 ya just so you can get it done faster!

ill work 4 ya just so you can get it done faster!

You mean it would fall apart like a JEEP :fawkdancesmiley:yea what is he going to sell it to ya for??? i am sure that you can have what ever you want with it... ill work in the store! you can have the zuk to yourself. plus if i did it. it would come out looking like a jeep! LOL!

um... my jeep is doing fine??? well thats cause it's been parked since i have no one to wheel with. but i will work for ya.

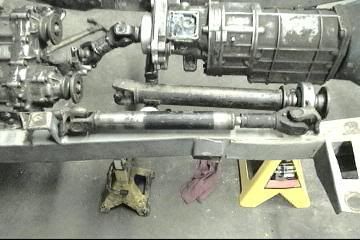

heres another pic of the weee lil zuke case just kinda hingin out in there gots to finish all the mounts.

Lookin good man. :awesomework: That zuk case should hold up just fine, I'd definately go with a cradle mount, adding the mount around the rear output. Really strengthens things up.

Why the divorced mounting?

um... my jeep is doing fine??? well thats cause it's been parked since i have no one to wheel with. but i will work for ya.

so when can i bring in the jeep??? it needs some work? lol:kissmybutt: