Been a long time coming,I finally got back on my samurai buggy project.I spent all day out in the shop finallizing my transmission to t-case adapter.So I can work on getting the the motor/trans/t-case mounted in the frame.

The specs:

Samurai body tub(to be pinned in the front and dove tailed in the back)

Samurai frame(reinforced)

2.3l pinto motor

bronco2 transmission(cause it was the shortest I could find and has 3.95:1 first gear)

samurai t-case with 6.5:1 gears/twin stick.

toy axles

scout steering box

swayaway air shocks

38" swampers

4-link front& back (with some help from you folks)

105"wheelbase

Now on to the start:

The trans was married to t-case in the bronco 2.So I have to build a back plate with bearings and seals,so I can use my devorsed zuke caes.First of all I had to build a doohicky to hold my adapter piece on the rotory table.

It fits like this

The first piece of the adapter looks like this,this piece bolts to the trans and holds 1 bearing and 1 seal.

Here is the other side machine index into it to,so the second piece is pecisely located on it.

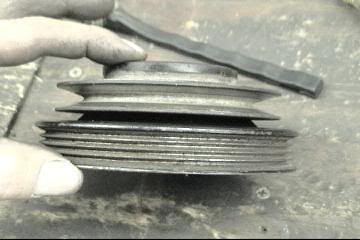

This is the second adapter piece,it holds 1 bearing and 2 seals(i dont want any leaks)

The adapter will bolt to this.

Center drilled and ready for the through holes.

Clamped down and ready for the transfer punch.

Thansfered/drilled and tapped.

This is the stub shaft I built out of a drivshaft yoke for a Ranger pu with auto trans.It had the right spline for my trans.Juist get to weld the 2 together.

Now I just got to get my 3/8 allen head bolts so I know what size to counter bore piece and how deep.Then I have the adapter all built.

Hope you enjoy the pics,**** was a ton of work.Im not a machinist just tired of waiting on and bothering my machinist friend with all my off the wall you cant buy this **** wants.LOL. So i bought a used lathe and new mill and some othere stuff.And dove in head first hehe.Im so stoked that all this **** actually fit together ,didnt scrap a piece.

More pics and progress to come.

The specs:

Samurai body tub(to be pinned in the front and dove tailed in the back)

Samurai frame(reinforced)

2.3l pinto motor

bronco2 transmission(cause it was the shortest I could find and has 3.95:1 first gear)

samurai t-case with 6.5:1 gears/twin stick.

toy axles

scout steering box

swayaway air shocks

38" swampers

4-link front& back (with some help from you folks)

105"wheelbase

Now on to the start:

The trans was married to t-case in the bronco 2.So I have to build a back plate with bearings and seals,so I can use my devorsed zuke caes.First of all I had to build a doohicky to hold my adapter piece on the rotory table.

It fits like this

The first piece of the adapter looks like this,this piece bolts to the trans and holds 1 bearing and 1 seal.

Here is the other side machine index into it to,so the second piece is pecisely located on it.

This is the second adapter piece,it holds 1 bearing and 2 seals(i dont want any leaks)

The adapter will bolt to this.

Center drilled and ready for the through holes.

Clamped down and ready for the transfer punch.

Thansfered/drilled and tapped.

This is the stub shaft I built out of a drivshaft yoke for a Ranger pu with auto trans.It had the right spline for my trans.Juist get to weld the 2 together.

Now I just got to get my 3/8 allen head bolts so I know what size to counter bore piece and how deep.Then I have the adapter all built.

Hope you enjoy the pics,**** was a ton of work.Im not a machinist just tired of waiting on and bothering my machinist friend with all my off the wall you cant buy this **** wants.LOL. So i bought a used lathe and new mill and some othere stuff.And dove in head first hehe.Im so stoked that all this **** actually fit together ,didnt scrap a piece.

More pics and progress to come.