RogueFab

Well-Known Member

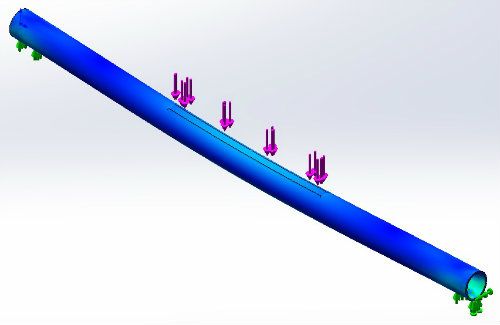

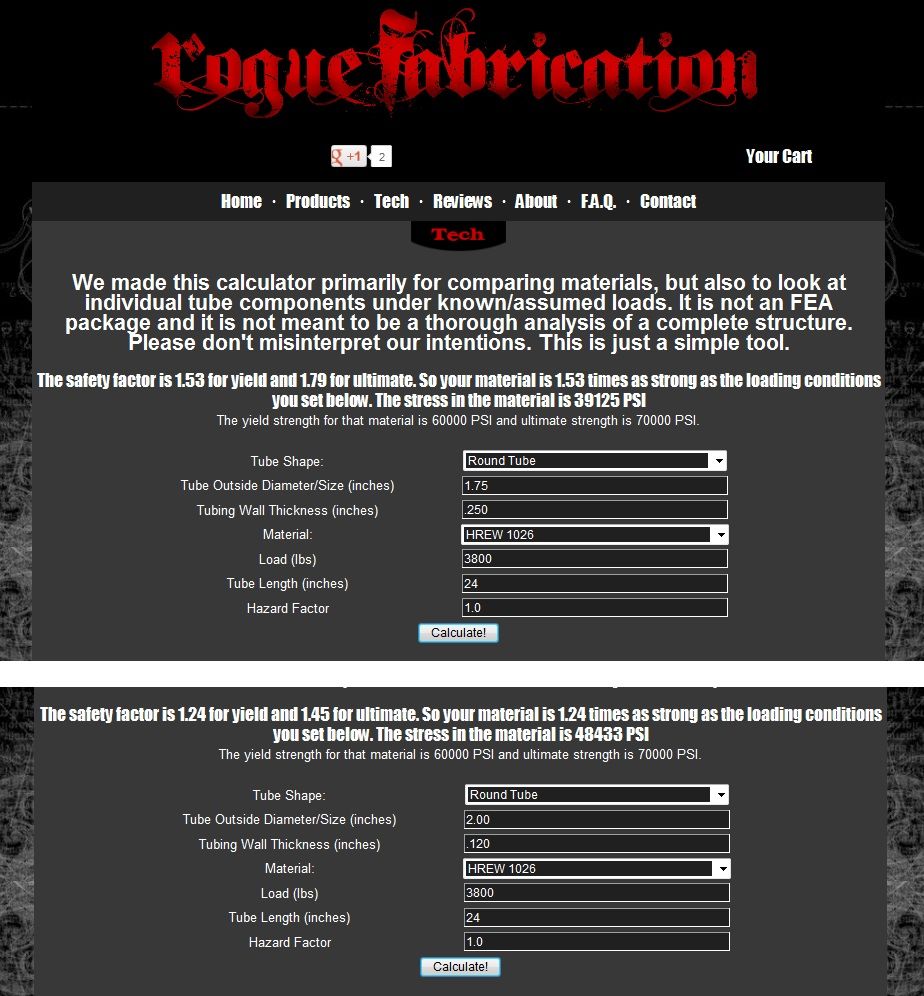

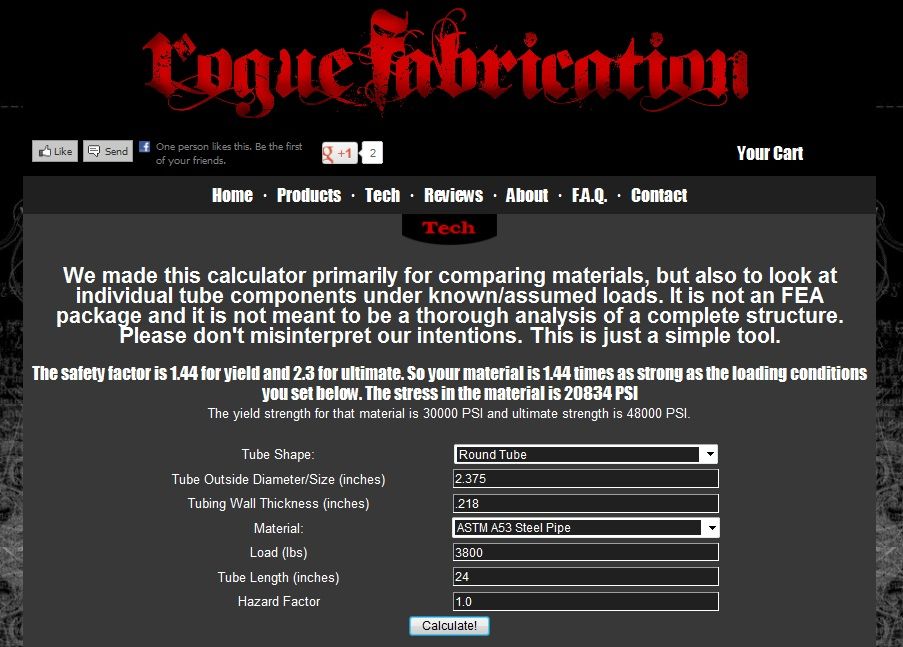

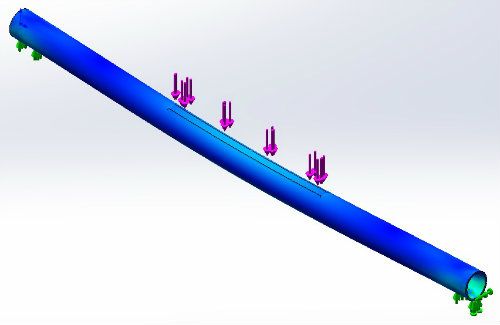

We made a tueb strength calculator because our customers are always asking us about material selection, and we figured all you fabricators out there could put this to use when comparing materials or trying to figure out what size of tube to build a frame/cage/bumper out of.

Let us know what you think and if you want to see anything added to it.

www.roguefab.com/calculator.php

Let us know what you think and if you want to see anything added to it.

www.roguefab.com/calculator.php