paradisepwoffrd

Well-Known Member

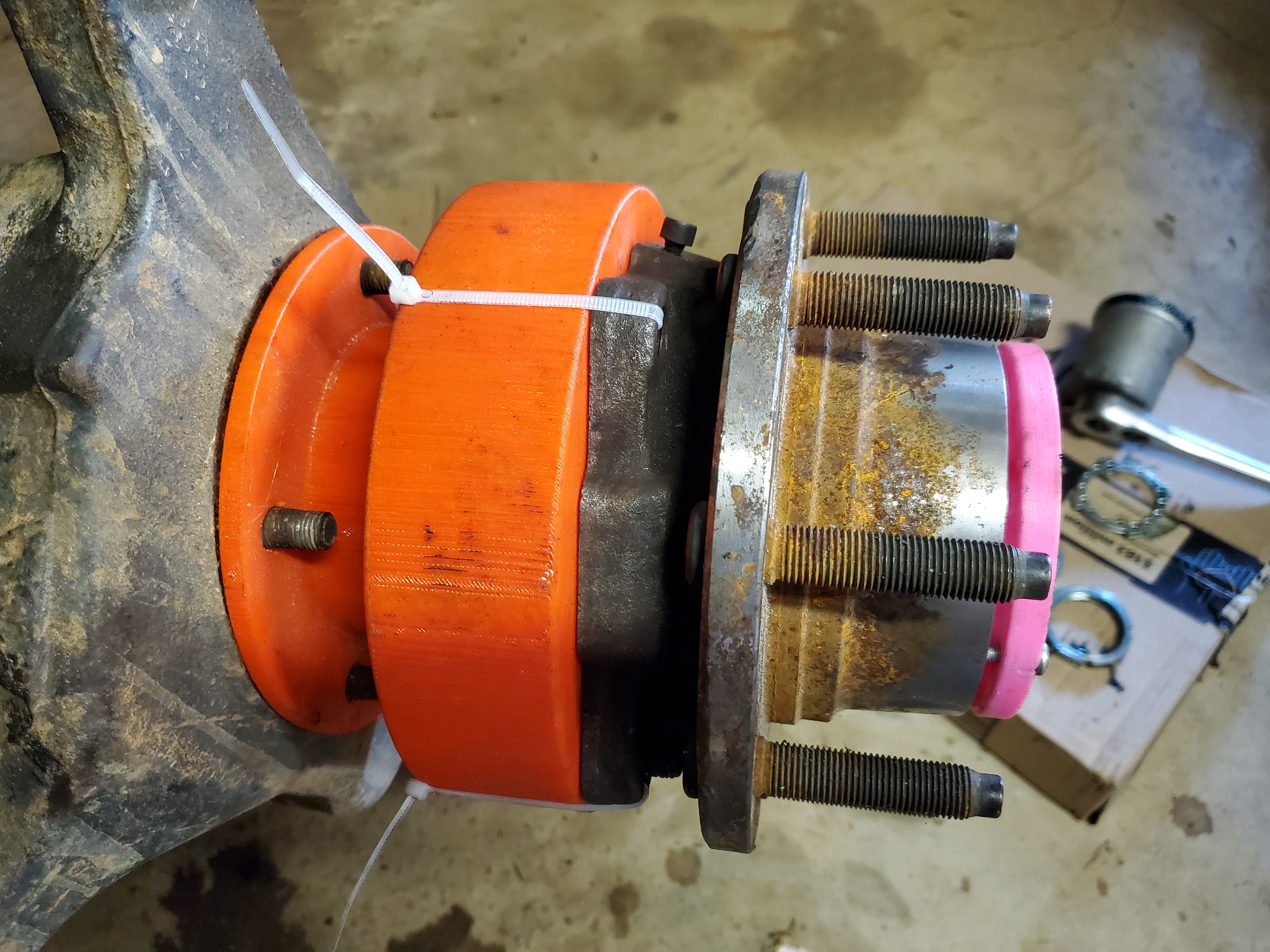

Was doing some maintenance to the rig and decided to test fit the pieces, since I had it apart.

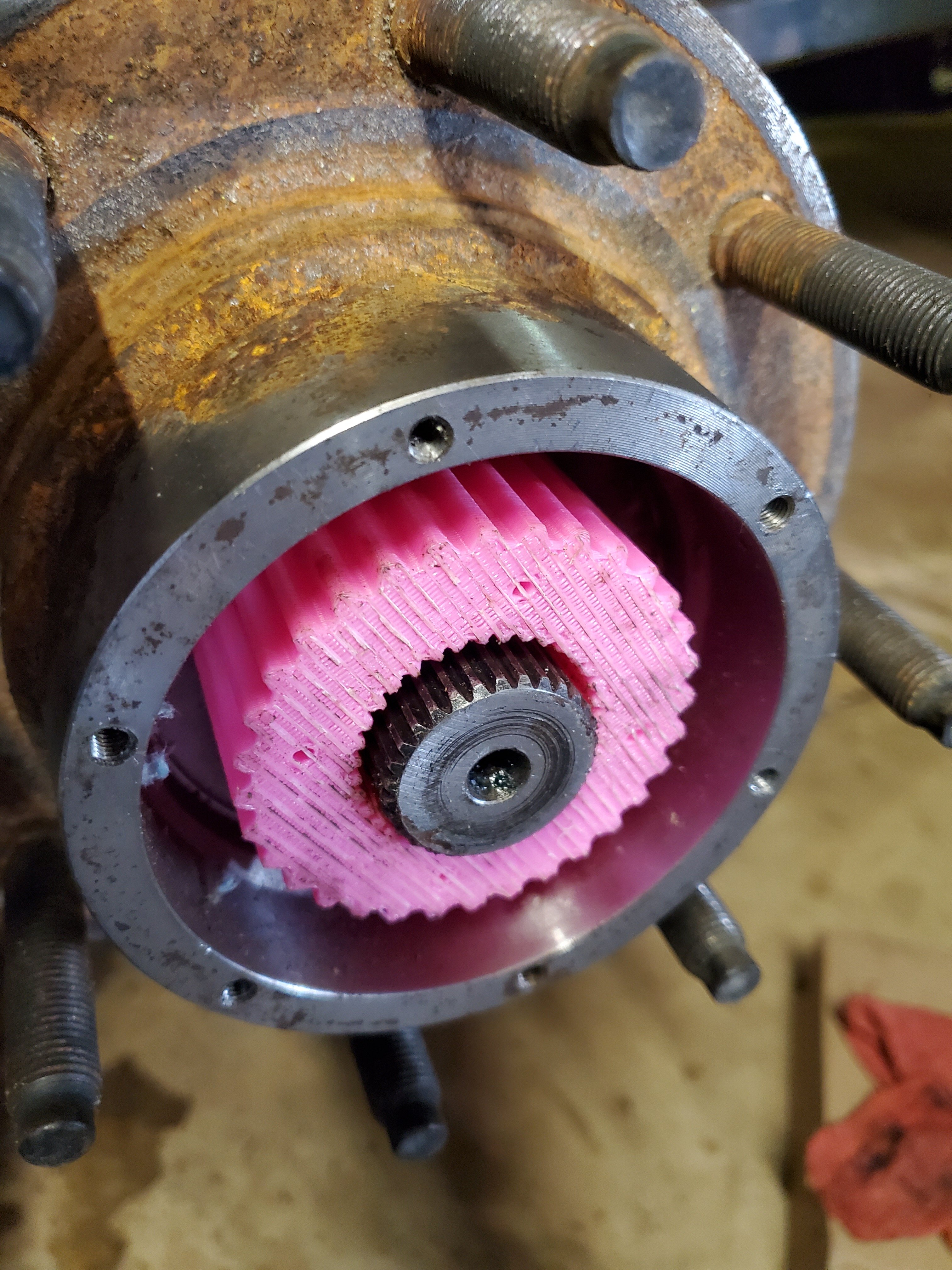

I didnt have the correct bolts/studs so ignore that part, but the dimensions seem to match up well. The slug and cap still need work to finish them out, but honestly that is the part most places would already know.

Would still need to figure out the brakes, but there should be plenty of room to adapt a bracket to work.

I didnt have the correct bolts/studs so ignore that part, but the dimensions seem to match up well. The slug and cap still need work to finish them out, but honestly that is the part most places would already know.

Would still need to figure out the brakes, but there should be plenty of room to adapt a bracket to work.