Binder

Well-Known Member

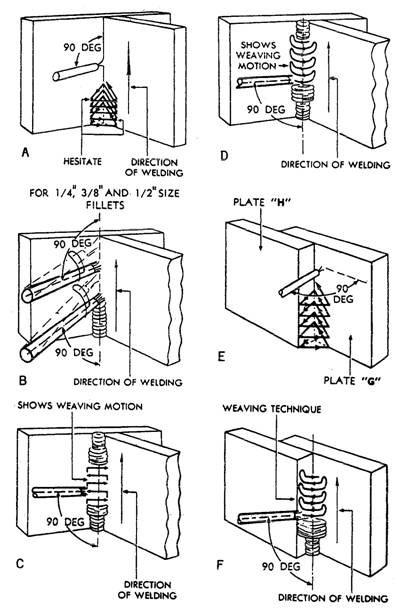

the correct way is up hill and creates a stronger weld FYI :awesomework::redneck::fawkdancesmiley:

But if im in a hurry i too weld downhill, but for the WABO tests that doesnt fly so i can do it either way:redneck:

WABO up or down are just two different certs. Most structural welding requires vert up though.

Floc that. I have a stick welder that I use to hold down the tarp on the wood pile

You don't have a hair on your ass if you can't run stick!:flipoff:

Charlie did you say specifically what wire you're using? It may not be suitable for verticle welding.