-

Help Support Hardline Crawlers :

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

widen a section of frame?

- Thread starter monstaru

- Start date

boardbysled

Tree Nerd.

Front end of your rig with the boxer motor?

LiftedZuki

Well-Known Member

Tube it out

KP81

Well-Known Member

round tube to cut down on the tires hitting the frame you are going to get by widening it, if you are running toyota axles since bigger tires hit the frame with it at stock width.

Sticking with leafs or going to links? that would play a big part in how much you could widen it with out causing a bunch of interference you would only have to worry about it closer to the firewall with links.

But if I were going to do it I would use cut every joint I was welding at an angle so there would be no vert welds, cover every joint with a fish mouth plate and add gussets where possible.

Im also guessing this is for the boxer. What are the dimensions compared to a 22re? Im guessing you are trying to keep the valve covers from getting scrubbed? or is it really tall enough to need to be placed further down in the frame rails?

Sticking with leafs or going to links? that would play a big part in how much you could widen it with out causing a bunch of interference you would only have to worry about it closer to the firewall with links.

But if I were going to do it I would use cut every joint I was welding at an angle so there would be no vert welds, cover every joint with a fish mouth plate and add gussets where possible.

Im also guessing this is for the boxer. What are the dimensions compared to a 22re? Im guessing you are trying to keep the valve covers from getting scrubbed? or is it really tall enough to need to be placed further down in the frame rails?

crash2

-Oh no I picked a side-

Depends on configuration or reason..

Some times 2x4 square works great, 1.5" round or 2" round tubing...

Some times 2x4 square works great, 1.5" round or 2" round tubing...

round tube to cut down on the tires hitting the frame you are going to get by widening it, if you are running toyota axles since bigger tires hit the frame with it at stock width.

Sticking with leafs or going to links? that would play a big part in how much you could widen it with out causing a bunch of interference you would only have to worry about it closer to the firewall with links.

But if I were going to do it I would use cut every joint I was welding at an angle so there would be no vert welds, cover every joint with a fish mouth plate and add gussets where possible.

Im also guessing this is for the boxer. What are the dimensions compared to a 22re? Im guessing you are trying to keep the valve covers from getting scrubbed? or is it really tall enough to need to be placed further down in the frame rails?

Yes , the boxer

I am keeping the springs for now.And planned on running some tube down from the upper supports on either side once done just for good measure.

But overall, I would only need about a foot on each side.

So I think it would be safe from the scrub....

I was thinking of putting a section of tube right up against the framerail, welding to the upper and lower seams then, fishplating and such .THEN cut out of the existing framerail what I need for clearance.and plate that obviously.so, overall not very long.

cheers

Last edited:

zukkev

Cornfuzzled yet again...

How much wider are you after??? With all the gusseting from shock mounts and such, couldn't you just section and fill in the inner side of the frame, essentially making that section slightly narrower for the clearance of the VC's??? I don't think you need to cut out the whole section of frame if i understand correctly...unless you are trying to drop the whole engine so the VC's are inside the framerail...:scratchhead:

CHOP SHOP

Well-Known Member

$500 used 22re and you could be wheelin in less than a week.

Just saying. A foot on each side is ALOT.

If each head is going to be wider than a frame rail, where the shocks going to go? They move alot in and out when cycled.

If the shocks dont rub the tires, then they have been pushed back almost to the frame, which is not going to need that space.

Shoulda just flipped the diffs and put that can of worms in the back.

Just saying. A foot on each side is ALOT.

If each head is going to be wider than a frame rail, where the shocks going to go? They move alot in and out when cycled.

If the shocks dont rub the tires, then they have been pushed back almost to the frame, which is not going to need that space.

Shoulda just flipped the diffs and put that can of worms in the back.

WA-Wheeler

Well-Known Member

can you even see out of that hole your digging??? just saying that the idea sounded cool but there is a point...... a point where it no longer becomes a build but a project. if you insist though I liked kevins idea......

good luck :awesomework::awesomework:

good luck :awesomework::awesomework:

LiftedZuki

Well-Known Member

I say go for it.

I prefer working on stuff than driving it.

I prefer working on stuff than driving it.

:haha:I knew it was gonna be a project.And aren't all builds projects?:flipoff:

I know , I know.I actually did some measuring a minute ago and think I can just clearance the frame for the Exhaust studs.

I was thinking along the lines of dropping the engine down in between the framerails.but

I do not "think" I need to do that.

Some of the points that I could tie into would defenitely reinforce everything else around it if I did though....

Im going to the run this weekend,so I will chat about it more I am sure:haha:

cheers

I know , I know.I actually did some measuring a minute ago and think I can just clearance the frame for the Exhaust studs.

I was thinking along the lines of dropping the engine down in between the framerails.but

I do not "think" I need to do that.

Some of the points that I could tie into would defenitely reinforce everything else around it if I did though....

Im going to the run this weekend,so I will chat about it more I am sure:haha:

cheers

$500 used 22re and you could be wheelin in less than a week.

Just saying. A foot on each side is ALOT.

If each head is going to be wider than a frame rail, where the shocks going to go? They move alot in and out when cycled.

If the shocks dont rub the tires, then they have been pushed back almost to the frame, which is not going to need that space.

Shoulda just flipped the diffs and put that can of worms in the back.

A fooot long from front to back, not a foot OUT on each side.:awesomework:

The heads arre literally the same axact width as the frame at the point it is mounted right now.

The shocks would have only 2 inches less on each side of which to cycle in towards the framerail.

Make sense?

cheers

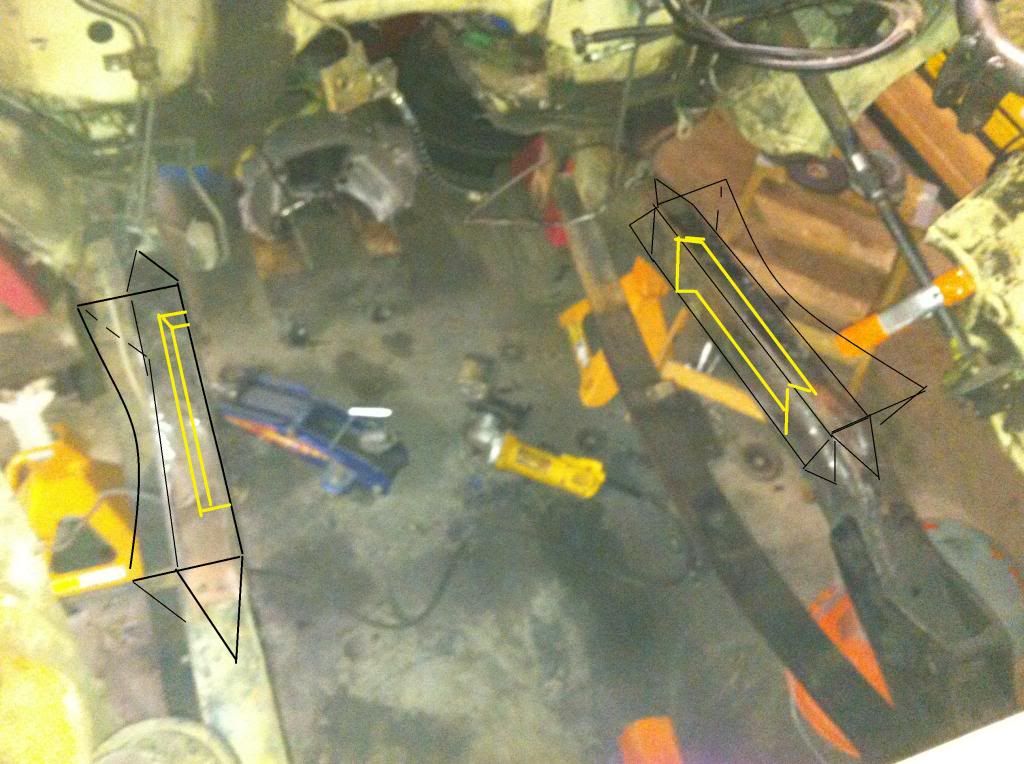

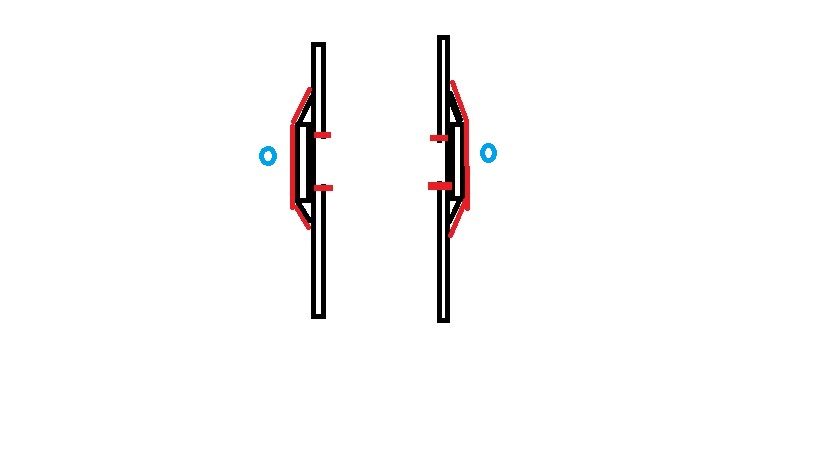

EDIT with my super awesome paint skills:brak =framerail and new framerail, red =fishplate and gussets ,brue=shocks

Last edited:

WA-Wheeler

Well-Known Member

Yes something like that is what I was picturing. If you do a brace over top (removable) between the shock hoops I would worry about any movement or weakness.

I understand where your coming from, but for me simplest option always seems the smartest. :awesomework:

I understand where your coming from, but for me simplest option always seems the smartest. :awesomework:

KP81

Well-Known Member

That makes much more sense, I thought you wanted the whole engine between the frame rails.

What you have drew up should work, you may have slight issues with shock clearance on the frame but you can over come that pretty easily by making new mounts for the shocks that locate them better for your application.

There is no such thing as a build that isnt a project. I am also attracted to the weird ****, I have to DD my truck right now so anything that isnt a quick change is put on the back burner.

What you have drew up should work, you may have slight issues with shock clearance on the frame but you can over come that pretty easily by making new mounts for the shocks that locate them better for your application.

There is no such thing as a build that isnt a project. I am also attracted to the weird ****, I have to DD my truck right now so anything that isnt a quick change is put on the back burner.

SJR

Well-Known Member

I have a subaru front clip you can weld on there :redneck: :awesomework: should clear just fine,

:awesomework: should clear just fine,

KP81

Well-Known Member

If all your taking out is the part in yellow, it looks like to me you are not even removing a whole section of frame?

If you are doing that why dont you drop a piece of box tube with a decent wall thickness .250" or so and use some .250" plate to fill the open spaces that would be left throw some fish mouth plates over all the joints, that gets you a wider opening for you engine to sit in with out actually widening the frame and should be plenty strong.

Its hard for me to tell exactly what you are trying to do with the frame because I cant see what you see, but that is what I get out of the picture. Why make the space your shocks are going to sit in smaller if you dont have to. Anything I said only makes sense if you are leaving a portion of frame if not chop away and put some pictures up of what you end up doing. I have been watching your build. I like where your going with this not that I would ever do it.

If you are doing that why dont you drop a piece of box tube with a decent wall thickness .250" or so and use some .250" plate to fill the open spaces that would be left throw some fish mouth plates over all the joints, that gets you a wider opening for you engine to sit in with out actually widening the frame and should be plenty strong.

Its hard for me to tell exactly what you are trying to do with the frame because I cant see what you see, but that is what I get out of the picture. Why make the space your shocks are going to sit in smaller if you dont have to. Anything I said only makes sense if you are leaving a portion of frame if not chop away and put some pictures up of what you end up doing. I have been watching your build. I like where your going with this not that I would ever do it.

I am looking at options .I would love to just cut an entire section of the frame out, and drop that motor down into it.But retaining the leaf springs kinda has me vexed.

I am not use to working with rigs that have frames:haha:So I usually just cut out what I do not want and rebuild it.

I was also thinking of just tying in the tube to everything surrounding the area I want to cut out,then cutting it out:redneck:

But I am afraid of what the spring load will do ..

cheers

I am not use to working with rigs that have frames:haha:So I usually just cut out what I do not want and rebuild it.

I was also thinking of just tying in the tube to everything surrounding the area I want to cut out,then cutting it out:redneck:

But I am afraid of what the spring load will do ..

cheers

SJR

Well-Known Member

if theres room I would take a 2x3 tube outside where the VC will sit and tie it into the stock frame then cut out the frame and box it in