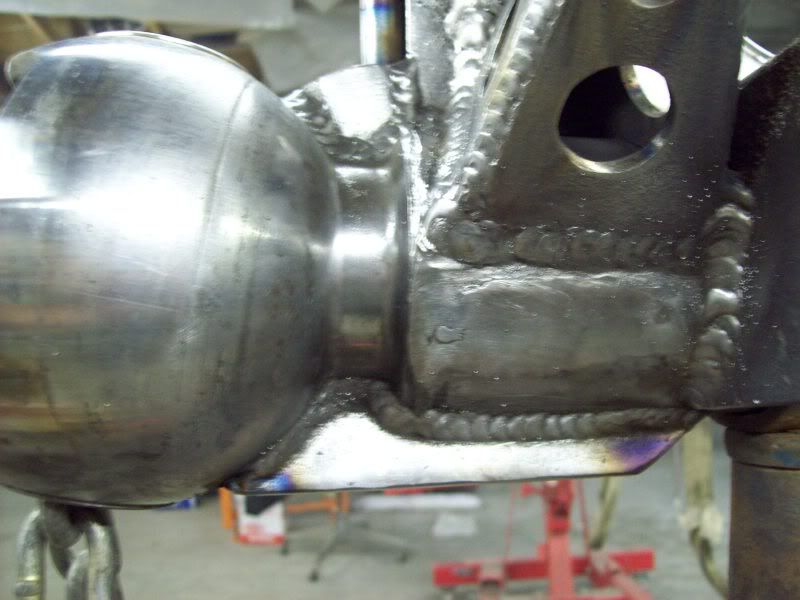

Thanks man,the adapter went pretty good as far as time.But i dunno,I kinda feel like the project is taking forever.

I thought I would be closer to a roller chassis by now.But the drivetrain swap/hunt/buy/convert thing killed a good 2 weeks.

It all still sits as the pics I posted last.I blew my backout last monday then tuesday I come down with the flue....so ya tuff week ,no progress.

But i did deside that im happy with the fit and location of everything so imjust going to drop back and finish the front housing then the rear suspension,build the skid plate mount system then tie the trans/t case mounts to that.

I thought I would be closer to a roller chassis by now.But the drivetrain swap/hunt/buy/convert thing killed a good 2 weeks.

It all still sits as the pics I posted last.I blew my backout last monday then tuesday I come down with the flue....so ya tuff week ,no progress.

But i did deside that im happy with the fit and location of everything so imjust going to drop back and finish the front housing then the rear suspension,build the skid plate mount system then tie the trans/t case mounts to that.