-

Help Support Hardline Crawlers :

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dynamite Design - Tacoma T-Rex

- Thread starter Dynamite Design

- Start date

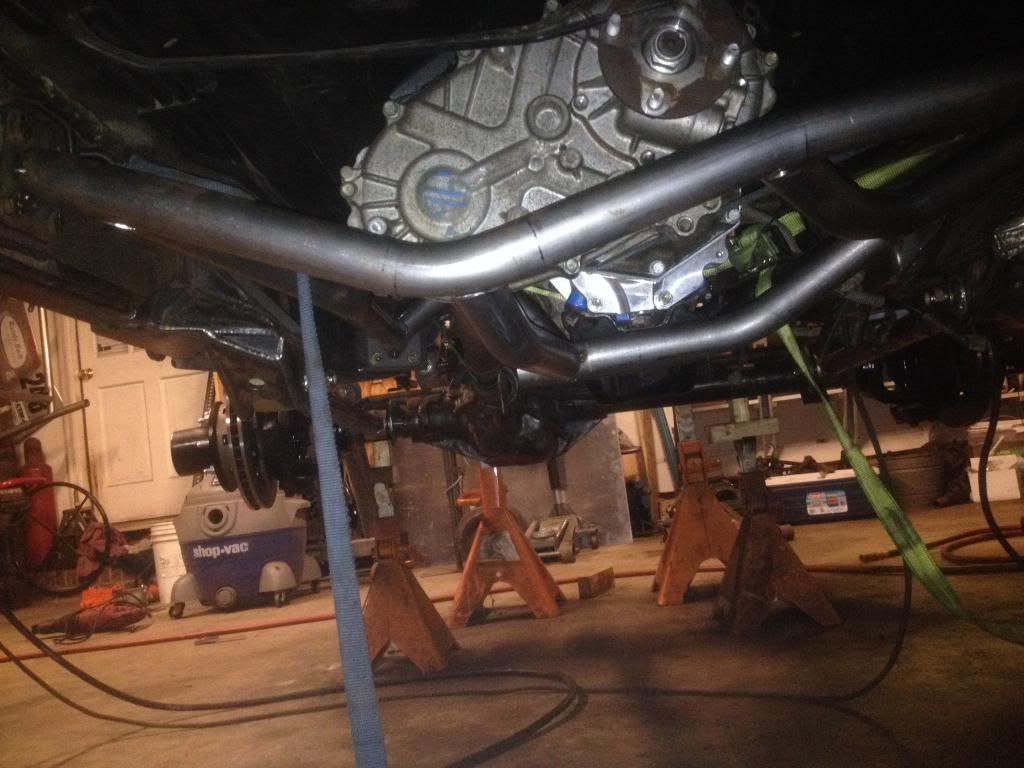

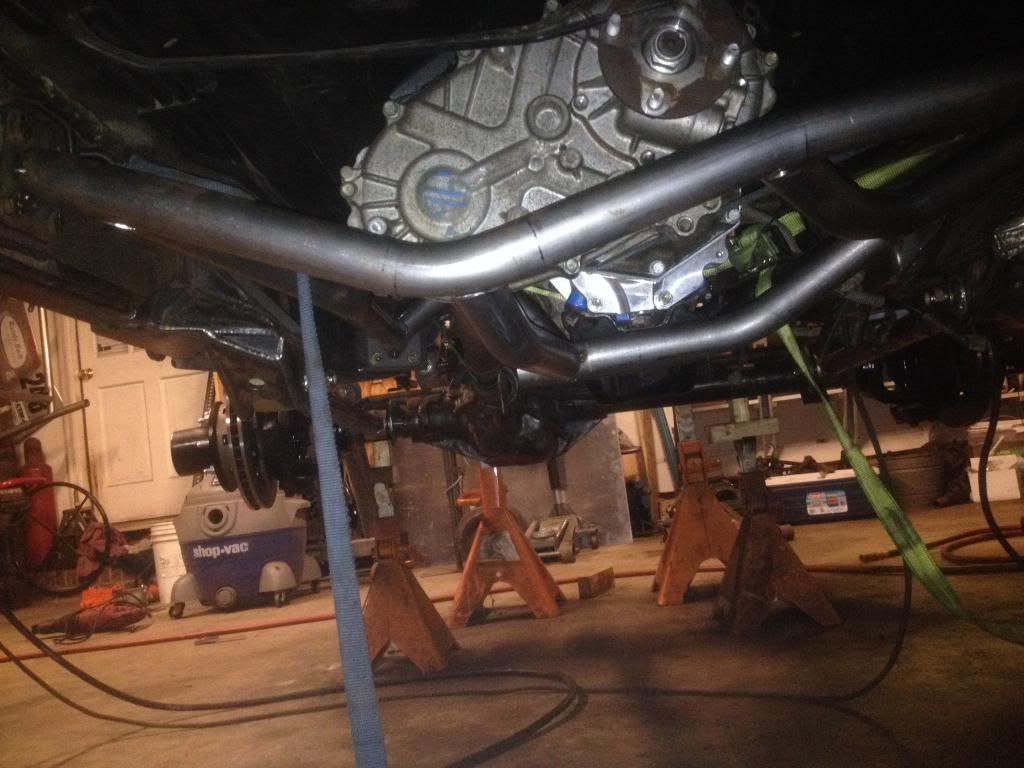

Next a crossmember skid plate was built to support the transmission, crawl box and transfer case. mounts were built to bolt the complete assembly to the frame so that it is easy to drop out and service the drive train should the need arise

you can see the OEM hack modified crossmember in the picture beside ours

you can see the OEM hack modified crossmember in the picture beside ours

tonybolton

Bypass Crawler

Re: Re: Dynamite Design - Tacoma T-Rex

I stand corrected. Very nice work and documentation!

Commence with the pimpin'... 8)

I stand corrected. Very nice work and documentation!

Commence with the pimpin'... 8)

redneckengineered

Trailer Park Panty Dropper

I need to address a few things.

1) David, nice shirt.

2) All build threads should be done by new guy from now on

3) It's spelled axle

Carry on

1) David, nice shirt.

2) All build threads should be done by new guy from now on

3) It's spelled axle

Carry on

Dynamite Design

Well-Known Member

- Joined

- Feb 4, 2014

- Messages

- 301

Thanks Andrew

L

lowbudgetjunk

Guest

Where was the PR guy on the first non-build thread? You may have found the missing link for your chain.

HotwheelsYJ

Well-Known Member

Re:

With a name like T-rex, I was expecting a short arm lift on the front.

With a name like T-rex, I was expecting a short arm lift on the front.

Re:

HotwheelsYJ said:With a name like T-rex, I was expecting a short arm lift on the front.

09zkrankin

Well-Known Member

Re:

Glad to see this build thread taking a much better direction than the last one. Build looks great

Sent from my SAMSUNG-SGH-I747 using Tapatalk

Glad to see this build thread taking a much better direction than the last one. Build looks great

Sent from my SAMSUNG-SGH-I747 using Tapatalk

TacomaJD

I LIKE CHEAP STUFF.....

lowbudgetjunk said:Where was the PR guy on the first non-build thread? You may have found the missing link for your chain.

x2 Subscribed. And I love Taco builds! drool

Eddyj

Well-Known Member

:Golf clap: well done sir, much improved. Thanks for sticking it out and staying on Hardline, besides all the drama ( which was entertaining ) I am interested In what you are going to do with your skills. Carry on.

Eddyj said::Golf clap: well done sir, much improved. Thanks for sticking it out and staying on Hardline, besides all the drama ( which was entertaining ) I am interested In what you are going to do with your skills. Carry on.

x2. New guy needs to wear the PR/forum posting hat, David you keep building stuff.

Thank you all for your complements and support, from both of us.

I am not sure if any of you have seen any of the 05+ Tacoma SAS that have been done yet, but I wanted to give you a little insight as to what we are trying to do with this rig. All of the 05+ Tacoma SAS that have been built to date are huge, all of them are sky high and most are running 40s. While that is great for the trail and the few who can afford it, and who have another vehicle to drive on week days, you might as well build a buggy. A truck with a ridiculous frame height and 40s, regardless of who you are is not a feasible daily driver for the masses. The cost of tires alone would kill your wallet. I want a truck that can crawl and be driven back and forth on a daily basis. When I started the research for this project, I found that there are just not a lot of companies even trying to do an SAS much less develop a kit. The only suspension upgrades available for these trucks are simple bolt on spacers and coil over kits, yielding around 3" of lift. With those kits, about $6000 more in parts, and major body modification you can only cram 36" tires in and still have limited wheel travel and weak steering and drive train components. There just are not parts available for this truck. With the venerable 1st, 2nd, and 3rd generation pickups and 4runners becoming impossible to find, people are turning to the Tacoma. Now they are turning to the 05+ Tacoma that is aging as well. From the start I wanted something that didn't exist. I realized very quickly that I was heading down the custom path. Shortly after that, I came to realize that I needed help. That is when I found David and both of us saw the opportunity to make a change in what is out there. While this truck is being built with custom style, I assure you it has been designed from the start as something that can be made into a production product very quickly. As this thing comes together you will see the complexity of what's going on. There are a lot of components being stuffed in between those frame rails and under that crossmember. I am sure here on Hardline, where the buggy guys roll heavy, you can appreciate what's going on under this full body rig.

Thanks again

I am not sure if any of you have seen any of the 05+ Tacoma SAS that have been done yet, but I wanted to give you a little insight as to what we are trying to do with this rig. All of the 05+ Tacoma SAS that have been built to date are huge, all of them are sky high and most are running 40s. While that is great for the trail and the few who can afford it, and who have another vehicle to drive on week days, you might as well build a buggy. A truck with a ridiculous frame height and 40s, regardless of who you are is not a feasible daily driver for the masses. The cost of tires alone would kill your wallet. I want a truck that can crawl and be driven back and forth on a daily basis. When I started the research for this project, I found that there are just not a lot of companies even trying to do an SAS much less develop a kit. The only suspension upgrades available for these trucks are simple bolt on spacers and coil over kits, yielding around 3" of lift. With those kits, about $6000 more in parts, and major body modification you can only cram 36" tires in and still have limited wheel travel and weak steering and drive train components. There just are not parts available for this truck. With the venerable 1st, 2nd, and 3rd generation pickups and 4runners becoming impossible to find, people are turning to the Tacoma. Now they are turning to the 05+ Tacoma that is aging as well. From the start I wanted something that didn't exist. I realized very quickly that I was heading down the custom path. Shortly after that, I came to realize that I needed help. That is when I found David and both of us saw the opportunity to make a change in what is out there. While this truck is being built with custom style, I assure you it has been designed from the start as something that can be made into a production product very quickly. As this thing comes together you will see the complexity of what's going on. There are a lot of components being stuffed in between those frame rails and under that crossmember. I am sure here on Hardline, where the buggy guys roll heavy, you can appreciate what's going on under this full body rig.

Thanks again

tonybolton

Bypass Crawler

Re: Re: Dynamite Design - Tacoma T-Rex

I like it! Keep on doin what you're doin!

I like it! Keep on doin what you're doin!

Dynamite Design

Well-Known Member

- Joined

- Feb 4, 2014

- Messages

- 301

Dynamite Design

Well-Known Member

- Joined

- Feb 4, 2014

- Messages

- 301

Josh has given the go ahead to redo all of the Fab work on the rear of his rig, and build a custom 3 link - cantilever suspension.

Almost everything we build for this front and rear 3 link system is designed to be produced as a kit. After we are done putting in the time of considering all of the variables, we should have one of the most solid 3 link systems for this style truck.

The front shock mounts were mig welded. I had to tig weld a set that is to be shipped to Australia. Now that Josh has seen the tig welded set, he wants the same thing on his rig.

I am going to go ahead and make 4 of our almost universal style shock mounts for this truck. They are stylish enough and versatile enough to use in the rear cantilever system. Also, just plain easy to work with, because you can connect them to the chassis, lots of different ways.

Almost everything we build for this front and rear 3 link system is designed to be produced as a kit. After we are done putting in the time of considering all of the variables, we should have one of the most solid 3 link systems for this style truck.

The front shock mounts were mig welded. I had to tig weld a set that is to be shipped to Australia. Now that Josh has seen the tig welded set, he wants the same thing on his rig.

I am going to go ahead and make 4 of our almost universal style shock mounts for this truck. They are stylish enough and versatile enough to use in the rear cantilever system. Also, just plain easy to work with, because you can connect them to the chassis, lots of different ways.

Dynamite Design

Well-Known Member

- Joined

- Feb 4, 2014

- Messages

- 301