-

Help Support Hardline Crawlers :

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why me??? Advice needed, cracked transmission housing. WTF.

- Thread starter kushKrawlin

- Start date

kushKrawlin

Well-Known Member

Hey fellas. Just caught up reading all this. Spent a wile last night gettin ready to take trans out, between smoking my whole sack and wipin tears away im at a point where help will be needed, so I don't become part of the concrete, transmission on top of me is not the way I want to go..

Now, after a lot of thought, I am NOT goin against Mr john or Patooyee, I personally think it would take a fool to Do that., I honestly believe that the rear drive shaft beating the **** outta the bottom of the rig the day before had to break it ! I read for days before mounting my ****, and it's been almost 2 years of driving, some was like ms daisy, and some was so rough I actually said "I'm sorry baby" to my rig. Hell it's been through a bunch of rough ****, **** like tryin to be cool and follow folks like John G will def let Ya know where Ur weaknesses are. And my lazy ass hasn't Cover the hole in the floor, so I know it has not been cracked for long. Just HAD to be when the drive shaft was jump roping under my rig. Now, that being said I DONT want to be in the same boat as some with this happening again and again!! So after I get the trans fixed, now I'm worried about me hard mounting it wrong!?? Or if I do, then some weird lil flex in my chassis (keep in mind I built it) and snappin again. That may be the breaking point if that happens. :****: anyways wanted to say thanks for the advice. I'm on a mission. I won't stop till it's fixed. unfortunately I have this addictive personality and this hobby, or sport some say, has me by the nuts. I'm sure some know what I'm talkin bout.

And chad, a nervous breakdown is a understatement... :****: Hope this made sense. Still tired from a late one. Time to get Goin on problem solving. No work for me (or very little) till this is fixed. Hope my lil white African helper carries his weight this week , cause my ass can't think bout nothing but my trans. ..

Now, after a lot of thought, I am NOT goin against Mr john or Patooyee, I personally think it would take a fool to Do that., I honestly believe that the rear drive shaft beating the **** outta the bottom of the rig the day before had to break it ! I read for days before mounting my ****, and it's been almost 2 years of driving, some was like ms daisy, and some was so rough I actually said "I'm sorry baby" to my rig. Hell it's been through a bunch of rough ****, **** like tryin to be cool and follow folks like John G will def let Ya know where Ur weaknesses are. And my lazy ass hasn't Cover the hole in the floor, so I know it has not been cracked for long. Just HAD to be when the drive shaft was jump roping under my rig. Now, that being said I DONT want to be in the same boat as some with this happening again and again!! So after I get the trans fixed, now I'm worried about me hard mounting it wrong!?? Or if I do, then some weird lil flex in my chassis (keep in mind I built it) and snappin again. That may be the breaking point if that happens. :****: anyways wanted to say thanks for the advice. I'm on a mission. I won't stop till it's fixed. unfortunately I have this addictive personality and this hobby, or sport some say, has me by the nuts. I'm sure some know what I'm talkin bout.

And chad, a nervous breakdown is a understatement... :****: Hope this made sense. Still tired from a late one. Time to get Goin on problem solving. No work for me (or very little) till this is fixed. Hope my lil white African helper carries his weight this week , cause my ass can't think bout nothing but my trans. ..

RustyC

Well-Known Member

- Joined

- Dec 15, 2010

- Messages

- 1,251

I agree with this. Adding in to tie the trans, transfer case mounts into one plate. Then a single mount on that plate.greenlion said:Poly tripod always works. Poly motor mounts mounted as close as possible to the block. Single poly trans mount in the center under the trans/t-case adapter. No additional t-case mounts.

This will force the engine mounts to stop the rotational torque.

Jeep chassis still flex a lot even with a cage tied in.

clemsonjeep

Well-Known Member

I'm obviously no expert in rigs with any more than 100hp...lol, but I'd have to say that the driveshaft beating around under the rig didn't break the trans case. It's gonna take some pretty significant force to make that happen. The motor mounts failing you would be where I'd put my money. I don't think I'd solid mount the drivetrain, but I'd definitely look at building some new mounts that use the leaf spring style poly bushings. Then use the same style bushings throughout the drivetrain.

One thing I'm still not clear on...is that atlas mount tied into the skid or is there a crossmember that runs between the frame rails with poly mounts at each end that it is attached to separate of the skid? I'd make it separate of the skid. I'd also put a crossmember between the rails at the transmission and use poly mounts at each end and fab up a mount at the transmission.

One thing I'm still not clear on...is that atlas mount tied into the skid or is there a crossmember that runs between the frame rails with poly mounts at each end that it is attached to separate of the skid? I'd make it separate of the skid. I'd also put a crossmember between the rails at the transmission and use poly mounts at each end and fab up a mount at the transmission.

Neal3000

Well-Known Member

Hey Kush, if you don't feel brave, I can swap your trans internals for you when you find a donor case

patooyee

Well-Known Member

- Joined

- Sep 27, 2008

- Messages

- 5,692

Neal3000 said:I have an Atlas, they don't have a nosecone so the cv or yoke is right beside the tailshaft of the trans. It also broke off the rear corner of the trans pan mounting surface, which was right in line with the crack. In fact i bet it hit that corner first which may have torqued the whole case. I don't know why it didn't punch a big hole in the case but it didn't. And i think the fact that it never happened before and hasn't happened since is pretty good proof that the shaft did in fact crack the case. Maybe if you had been smart enough to go to GT instead of ugay you could understand this

As far as Kush's **** goes i totally agree that he needs to fix his mounts, that **** under his trans adapter looks like something a pot-smoking crackhead would fab up. And how did he find the crack, did it just start leaking fluid?

This is kind of where I was having a hard time understanding you. I was finding it hard to imagine how the driveshaft would contact the tail housing directly. But ya, if it did I would say that's a pretty good reason for it to crack.

kushKrawlin

Well-Known Member

Awesome!! And no I don't feel brave! Ha. Text me so I have Ur number please. 4048892714 thanks so much.Neal3000 said:Hey Kush, if you don't feel brave, I can swap your trans internals for you when you find a donor case

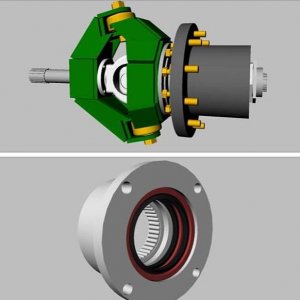

And man why u say it looked like that ? It's a TMR kit. Here's pic with skid removed.

Attachments

Neal3000

Well-Known Member

patooyee said:This is kind of where I was having a hard time understanding you. I was finding it hard to imagine how the driveshaft would contact the tail housing directly. But ya, if it did I would say that's a pretty good reason for it to crack.I thought you were saying that the side of the trans just got whacked so hard that the tail housing sheared. That was hard for me to imagine. It would be like me bitch-slapping someone in the face so hard that their hip broke but there was no damage to their face.

John Galbreath Jr.

38 Special & Solo Buggy

- Joined

- May 24, 2007

- Messages

- 8,613

First off, the trans broke Saturday night at Choccolocco Mountain where we worked for an hour tying your motor back to the frame. The motor was completely loose when we started. We left from there, downhill to camp and did not ride again.

The drive shaft was a freak, or perhaps installed too loose, or to tight, or stretched U-bolts. I would not dwell on that.

Here is what I would do to get back on the trail the fastest and cheapest. But, probably not best practices.

Put new caps on **IF** the cross is perfect. Put in new U-bolts.

Buy the same style motor mounts and use large washers to keep the possibility of bolts pulling through again out. Putting the washers in the kit in the right place this time.

I would not change the rubber blocks on the front Altas mount as they are rubber mounted on the ends. My opinion is that part (Atlas) did not move, motor did. Trans case broke.

I would take to to a great tig welding place and see if they will weld the case. As it did not break through the bolt holes, at lease the ones we can see.

Put it back together and don't follow me any more

Couple hundred dollars and back on trail for Stony Lonesome Hardline Ride in two weeks.

*OR* think off all the right and wrong ways to do it, smoke reefer, re-do all the mounts, smoke reefer, re-built the transmission, smoke reefer, install everything, smoke reefer, dwell that you did not do it right, smoke reefer, take apart, smoke reefer, decide it was okay after all, smoke reefer, put all back in, smoke reefer. You are going to miss the Christmas rides.

The drive shaft was a freak, or perhaps installed too loose, or to tight, or stretched U-bolts. I would not dwell on that.

Here is what I would do to get back on the trail the fastest and cheapest. But, probably not best practices.

Put new caps on **IF** the cross is perfect. Put in new U-bolts.

Buy the same style motor mounts and use large washers to keep the possibility of bolts pulling through again out. Putting the washers in the kit in the right place this time.

I would not change the rubber blocks on the front Altas mount as they are rubber mounted on the ends. My opinion is that part (Atlas) did not move, motor did. Trans case broke.

I would take to to a great tig welding place and see if they will weld the case. As it did not break through the bolt holes, at lease the ones we can see.

Put it back together and don't follow me any more

Couple hundred dollars and back on trail for Stony Lonesome Hardline Ride in two weeks.

*OR* think off all the right and wrong ways to do it, smoke reefer, re-do all the mounts, smoke reefer, re-built the transmission, smoke reefer, install everything, smoke reefer, dwell that you did not do it right, smoke reefer, take apart, smoke reefer, decide it was okay after all, smoke reefer, put all back in, smoke reefer. You are going to miss the Christmas rides.

paradisepwoffrd

Well-Known Member

RustyC said:I agree with this. Adding in to tie the trans, transfer case mounts into one plate. Then a single mount on that plate.

This will force the engine mounts to stop the rotational torque.

Jeep chassis still flex a lot even with a cage tied in.

X2. I would tie the trans mount, adapter mount, and rear tcase mount into a solid plate that had a center poly tube bushing under it, to a solid mounted crossmember. Then use the poly tube bushing on the motor mount. This will tie the trans/tcase mount together and allow it to pivot some based on the engine mounts.

Many of these trans had torque arms from the factory that tied the trans mount and bellhousing bolts together to help with case flex.

yjwrangler95

Well-Known Member

- Joined

- Jan 4, 2011

- Messages

- 144

OR* think off all the right and wrong ways to do it, smoke reefer, re-do all the mounts, smoke reefer, re-built the transmission, smoke reefer, install everything, smoke reefer, dwell that you did not do it right, smoke reefer, take apart, smoke reefer, decide it was okay after all, smoke reefer, put all back in, smoke reefer. You are going to miss the Christmas rides. JohnG

Funnies thing I've read all day.

Funnies thing I've read all day.

zjtrey

Well-Known Member

paradisepwoffrd said:Many of these trans had torque arms from the factory that tied the trans mount and bellhousing bolts together to help with case flex.

excellent point… even jeep grand cherokee's had these strut rods starting in 99 or so..

FlatlandFSJ

Well-Known Member

I think we all know Kush wouldn't be caught with a sack that looked like that...its not neon green :smoke:

TJTJ

Member

I agree with the tripod theory. Weld your trans and atlas support to a common plate. Then put a bushing on the plate to where it will be in the center of the frame rails. Then build a crossmember that will connect to your bushing. Oh and get better motor mounts! Yours look sketchy

June dog

Well-Known Member

For what it's worth this is how mines mounted. Sorry for crappy pictures. But both of my cross members are bolted solid to the factory frame rails.. Not sure if you can see but the transfercase foot is mounted on factory style poly bushings the home made transfercase support is mounted with poly bushings and I have the same style poly bushings on my motor mounts. When my trans broke I didn't have any rear support on my 205 and the adapter bolts worked loose witch caused my case to bust. It actually broke one of the ears off the back of the case but we welded it all back up solid drilled it out and help coiled it. It's been over a year and I've been good to go. I'm wondering if where your cross member is poly mounted if you couldn't bolt your transfer to it solid. There would still be give at the side mounting points. Good luck and I hope you get this problem taken care of.

Attachments

June dog

Well-Known Member

Son of a bitch there upside down. I hate this friggin iPad

kushKrawlin

Well-Known Member

I agree 100%. After a lot of thinking, it had to be what you were talking about. The trans will be out tonite. Made a call and a buddy took me to meet a guy today that has been doing transmissions since he was old enough to work. Nice lil shop, clean as a whistle. 200 total to swap to a new case. Talked to him about upgrades in clutches, and other parts. He explained a lot of cool stuff. But 200 is much better for me right now rather than 1100 for totally upgraded with reverse shift pattern. Just can't do that right now. Wish I could. Anyways he said it would be ready bu this weekend. So that's the plan. Would like to hard mount but I know for a fact my "pothead crack head fabbed ****" worked just fine before the motor mount bolt pulled through the bottom weak ass washer. .. About 20+ trips and a **** ton of drive time prove that .. I don't care for the "biscut" type motor mounts , if anyone has link to some good motor mounts that would be awesome. By the time I get these kind tight it seems The metal pieces are squeezing together. Anyhow I will be at STL for the ride. U can bet on it. And you were off one reefer break señior John. :smoke:JohnG said:First off, the trans broke Saturday night at Choccolocco Mountain where we worked for an hour tying your motor back to the frame. The motor was completely loose when we started. We left from there, downhill to camp and did not ride again.

The drive shaft was a freak, or perhaps installed too loose, or to tight, or stretched U-bolts. I would not dwell on that.

Here is what I would do to get back on the trail the fastest and cheapest. But, probably not best practices.

Put new caps on **IF** the cross is perfect. Put in new U-bolts.

Buy the same style motor mounts and use large washers to keep the possibility of bolts pulling through again out. Putting the washers in the kit in the right place this time.

I would not change the rubber blocks on the front Altas mount as they are rubber mounted on the ends. My opinion is that part (Atlas) did not move, motor did. Trans case broke.

I would take to to a great tig welding place and see if they will weld the case. As it did not break through the bolt holes, at lease the ones we can see.

Put it back together and don't follow me any more

Couple hundred dollars and back on trail for Stony Lonesome Hardline Ride in two weeks.

*OR* think off all the right and wrong ways to do it, smoke reefer, re-do all the mounts, smoke reefer, re-built the transmission, smoke reefer, install everything, smoke reefer, dwell that you did not do it right, smoke reefer, take apart, smoke reefer, decide it was okay after all, smoke reefer, put all back in, smoke reefer. You are going to miss the Christmas rides.

Neal3000

Well-Known Member

These are what i have always used

http://www.advanceadapters.com/products/713008-ns--advance-adapters-engine-mount-replacement-cushion-kit/

http://www.advanceadapters.com/products/713008-ns--advance-adapters-engine-mount-replacement-cushion-kit/

John Galbreath Jr.

38 Special & Solo Buggy

- Joined

- May 24, 2007

- Messages

- 8,613

Neal3000 said:These are what i have always used

http://www.advanceadapters.com/products/713008-ns--advance-adapters-engine-mount-replacement-cushion-kit/

If you change motor mount part numbers. Make sure the spacing from steel to steel is the same. If the rubber is thinner or thicker, you will have to adjust a steel mount to compensate.