-

Help Support Hardline Crawlers :

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1985 toy axle hub/spindle new?

- Thread starter notstock

- Start date

WHITE TRASH1

fruit stripe

Well if you'd get off your ass and come over here i have a few of them sitting here.. Hell I'll even toss one in the solvent tank for ya. :flipoff:

notstock

Well-Known Member

- Joined

- Mar 28, 2006

- Messages

- 2,461

why new?

and no..i have no idea.

I have a birf eliminator kit, the back surface will need to be machined to work with the kit. I would much rather use a new piece if it will need to be machined to work.

I have a birf eliminator kit, the back surface will need to be machined to work with the kit. I would much rather use a new piece if it will need to be machined to work.

Is it a redline kit????

WHITE TRASH1

fruit stripe

Is it a redline kit????

Yep.

Hmm this explains why notstock won't run anything over a 33" tire.. I forgot about the birf elim kit... :fawkdancesmiley:

can i ask why you went with an eliminator kit? uses warn hubs? or yotas hubs?I have a birf eliminator kit, the back surface will need to be machined to work with the kit. I would much rather use a new piece if it will need to be machined to work.

id originally thought about doing the same. then i hear it uses the warn hubs, which are nowhere near as strong as the aisin hubs, and a u-joint..that can get dry, and break just as easy as anything.

thats when i decided that it wasnt for me...

WHITE TRASH1

fruit stripe

He's had that redline kit since before bobby got into yota axle's..... :;

ah, that makes sense.He's had that redline kit since before bobby got into yota axle's..... :;

every broken anything? im assuming YES, since hes looking for spare parts....

notstock

Well-Known Member

- Joined

- Mar 28, 2006

- Messages

- 2,461

You are always such a big help WT, I just don't quite know how to thank you.:fawkdancesmiley:

The bearing surface on the spindle hub is toast, there is .005 play causing wheel wobble hence the need for a new hub. Nothing else has failed ...yet. I just don't have 600+ for longs at this point. This is one of the first 5 Redline kits made. I was a crash test dummy. The spindle hub has 300,000,000+ on it since it was in this truck.

The bearing surface on the spindle hub is toast, there is .005 play causing wheel wobble hence the need for a new hub. Nothing else has failed ...yet. I just don't have 600+ for longs at this point. This is one of the first 5 Redline kits made. I was a crash test dummy. The spindle hub has 300,000,000+ on it since it was in this truck.

Last edited:

You are always such a big help WT, I just don't quite know how to thank you.:fawkdancesmiley:

The bearing surface on the spindle hub is toast, there is .005 play causing wheel wobble hence the need for a new hub. Nothing else has failed ...yet. I just don't have 600+ for longs at this point. This is one of the first 5 Redline kits made. I was a crash test dummy. The spindle hub has 300,000,000+ on it since it was in this truck.

When you say bearing surface are you talking about the brass bushing he pressed into the spindle? If so i could make ya a new one..or several.

With that said, I will start a caption this thread:cheer:

WHITE TRASH1

fruit stripe

Actually Dan why don't you just have a chat with my buddy bunk there... I think he may know a thing or 3 about doing machine work.... My money is he could do what needs to be done at a rather reasonable rate.. :;

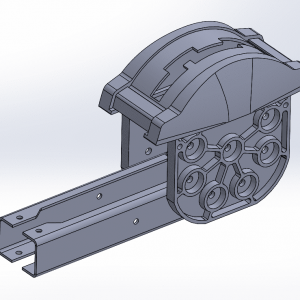

It is easier to show a picture than explain. The Brass bush is removed & the back of the mating plate is machined. The surface where the wheel bearings ride on the spindle is scored & worn rendering the spindle toast.

aah..yer ****ed...Kinda like when we were wheelin at the top of 676 and keiths high performance ifs mods fell apart!!:redneck:

notstock

Well-Known Member

- Joined

- Mar 28, 2006

- Messages

- 2,461

:haha: High performance mods

My plan is to find a spindle hub & have the backing plate machined so I can run this until spring when I have enough to buy longs. Shouldn't be that hard. Just wanted to buy 2 new spindle hubs & have them machined to work. I plan on giving this kit to my daughter for her truck in the spring.

My plan is to find a spindle hub & have the backing plate machined so I can run this until spring when I have enough to buy longs. Shouldn't be that hard. Just wanted to buy 2 new spindle hubs & have them machined to work. I plan on giving this kit to my daughter for her truck in the spring.

CHOP SHOP

Well-Known Member

I plan on giving this kit to my daughter for her truck in the spring if they havent blown into chunks by then.:booo:

fixed:awesomework:

notstock

Well-Known Member

- Joined

- Mar 28, 2006

- Messages

- 2,461

fixed:awesomework:

:haha: :haha: :haha:

you could just have it repaired. would be nothing for a decent machine shop to take care of.It is easier to show a picture than explain. The Brass bush is removed & the back of the mating plate is machined. The surface where the wheel bearings ride on the spindle is scored & worn rendering the spindle toast.

less than a NEW spindle, thats for sure.

BUT...theres got to be used spindles that are in good shape out there.

isnt there a few yota fronts in the FS section? without a 3rd, theyre cheap....also cheaper than a new spindle.

84Toyota4x4

Well-Known Member

I dont think wearing down the bearing surface for your wheel bearings counts as breaking anything inside the axle for this time around, haha.every broken anything? im assuming YES, since hes looking for spare parts....

How would you plan on repairing the wheel bearing surface of the spindle? Its machined to a diameter for the inside of the bearing/race. If its scored, you could only make it smaller by machining/grinding/polishing it down smaller, and since he said its already too small causing a wheel wobble... I guess you could machine it and then make a custom sleeve like a speedy sleeve for it, but I think finding a new/used spindle would be easieryou could just have it repaired. would be nothing for a decent machine shop to take care of.

less than a NEW spindle, thats for sure.

He wants a new spindle because the wheel bearing area is scored from what I understand. The point is that after he gets a new spindle to solve that problem, it needs to be machined as shown so that it will work with the birf kit he has.

I would try and find used ones myself though, and just have those machined to work. I dont see why it would make a big difference other than being clean or not since the brass bushing on the inside of the spindle is changed to a different one anyway (at least I think it is). So, as long as the wheel bearing surface is good on the outside of the spindle, the threads are good for the wheel bearing nuts you should be ok since you dont re-use the Toyota brass bushing (right?). There are no other "wear" surfaces on the spindles, so new or used shouldnt matter too much IMO.

Then again, what do I know. I run 30 spline Longfields :fawkdancesmiley:

~T.J.

Last edited:

thats easy. they build it up with weld, and machine it back to spec. VERY easy.I dont think wearing down the bearing surface for your wheel bearings counts as breaking anything inside the axle for this time around, haha.

How would you plan on repairing the wheel bearing surface of the spindle? Its machined to a diameter for the inside of the bearing/race. If its scored, you could only make it smaller by machining/grinding/polishing it down smaller, and since he said its already too small causing a wheel wobble... I guess you could machine it and then make a custom sleeve like a speedy sleeve for it, but I think finding a new/used spindle would be easier

He wants a new spindle because the wheel bearing area is scored from what I understand. The point is that after he gets a new spindle to solve that problem, it needs to be machined as shown so that it will work with the birf kit he has.

I would try and find used ones myself though, and just have those machined to work. I dont see why it would make a big difference other than being clean or not since the brass bushing on the inside of the spindle is changed to a different one anyway (at least I think it is). So, as long as the wheel bearing surface is good on the outside of the spindle, the threads are good for the wheel bearing nuts you should be ok since you dont re-use the Toyota brass bushing (right?). There are no other "wear" surfaces on the spindles, so new or used shouldnt matter too much IMO.

Then again, what do I know. I run 30 spline Longfields :fawkdancesmiley:

~T.J.

but i agree finding a good used one would be the way to go.

im curious..how did the spindle get worn..THERE?

bearings were loose? the race would have to be spinning to wear it...