under_psi

CROSS POST POLICE

like the title says...i need it....maybe motivation more than anything....

i can not tell you guys how frustrated i am with building this buggy....just needed to get that out there...

i feel like i am falling behind the 8 ball everyday, and there is always a little something that holds up progress...chassis was painted, have to go back and add tubing....wiring was a pain in the ass, etc, yes, i know....every buggy has its pita things.....maybe i am just bein a *****, but i feel like a tard sometimes b/c i only get a few hours a week to work on this thing while trying to balance a life with my wife and time with the dog pound.....

today for example....

i am READY TO GET THIS MOFO STARTED, but was gonna wait until i was not alone (for multiple reasons, burning down the house is one...), and i had just a couple of little ghey things to do like hook up a ground wire or two, and so on....

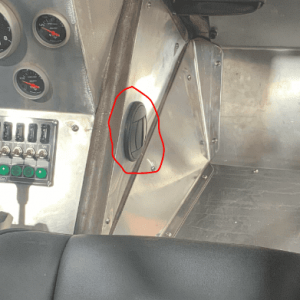

another thing that i was doing today was fiddling with all of the autometer and spal senging unitsfor the 11ty billionth time...i had added all the fluids to the engine and steering systems, and jimmy the blade helped me prime the engine.....well, i noticed an oil leak at the oil temp sending unit and at both of my water temp sensors (1 for the radiator fan and the other for the guage-both in the aluminum lower plenum)....well, i noticed that i did not put any teflon tape on those main bushings that the sending units go into so, i took them out, taped 'em up, re-re-reinstalled them, and all was good....small leak, and a little tightening took care of that.....

well, i think more of it and wonder if that is going to affect the sending units ground circuit, and, after a little talking with some peeps, i decided to take them out aaaaaagain....cleaned off all the BS teflon tape pieces and proceeded to rererererefukkin install the sending units and well, damn-it, the leaks are back!!!!!....

i figured that the bushings were brass and gave the one at the plenum another snug turn and POP........and the bushing was not as tight as it was a second ago....but still tight....well, as i am backing it out to have a look-see, i notice there are 2 fawkin cracks in the threads that go all the way through the plenum casting there....

yup, gonna need a new plenum.....have to undo all that wiring, fuel lines, and other crap on there that i JUST got done tidying up....

so...now it looks like it is going to be a 5 step back week moneywise for me b/c i am already broker than a broke **** dog with his tongue out.....

that's the breaks, i know...

just felt like doing a little venting b/c it has not been teh easiest of journeys for me.....

oh, and if anyone has a lead on an intake plenum for a 2000 vortec 4.3, lemme know...it is the one with that funky MPFI all in one composite fuel rail injector bundle thingy on top of it........

i can not tell you guys how frustrated i am with building this buggy....just needed to get that out there...

i feel like i am falling behind the 8 ball everyday, and there is always a little something that holds up progress...chassis was painted, have to go back and add tubing....wiring was a pain in the ass, etc, yes, i know....every buggy has its pita things.....maybe i am just bein a *****, but i feel like a tard sometimes b/c i only get a few hours a week to work on this thing while trying to balance a life with my wife and time with the dog pound.....

today for example....

i am READY TO GET THIS MOFO STARTED, but was gonna wait until i was not alone (for multiple reasons, burning down the house is one...), and i had just a couple of little ghey things to do like hook up a ground wire or two, and so on....

another thing that i was doing today was fiddling with all of the autometer and spal senging unitsfor the 11ty billionth time...i had added all the fluids to the engine and steering systems, and jimmy the blade helped me prime the engine.....well, i noticed an oil leak at the oil temp sending unit and at both of my water temp sensors (1 for the radiator fan and the other for the guage-both in the aluminum lower plenum)....well, i noticed that i did not put any teflon tape on those main bushings that the sending units go into so, i took them out, taped 'em up, re-re-reinstalled them, and all was good....small leak, and a little tightening took care of that.....

well, i think more of it and wonder if that is going to affect the sending units ground circuit, and, after a little talking with some peeps, i decided to take them out aaaaaagain....cleaned off all the BS teflon tape pieces and proceeded to rererererefukkin install the sending units and well, damn-it, the leaks are back!!!!!....

i figured that the bushings were brass and gave the one at the plenum another snug turn and POP........and the bushing was not as tight as it was a second ago....but still tight....well, as i am backing it out to have a look-see, i notice there are 2 fawkin cracks in the threads that go all the way through the plenum casting there....

yup, gonna need a new plenum.....have to undo all that wiring, fuel lines, and other crap on there that i JUST got done tidying up....

so...now it looks like it is going to be a 5 step back week moneywise for me b/c i am already broker than a broke **** dog with his tongue out.....

that's the breaks, i know...

just felt like doing a little venting b/c it has not been teh easiest of journeys for me.....

oh, and if anyone has a lead on an intake plenum for a 2000 vortec 4.3, lemme know...it is the one with that funky MPFI all in one composite fuel rail injector bundle thingy on top of it........