Crank R&R 101... pistons and rods still in the block.

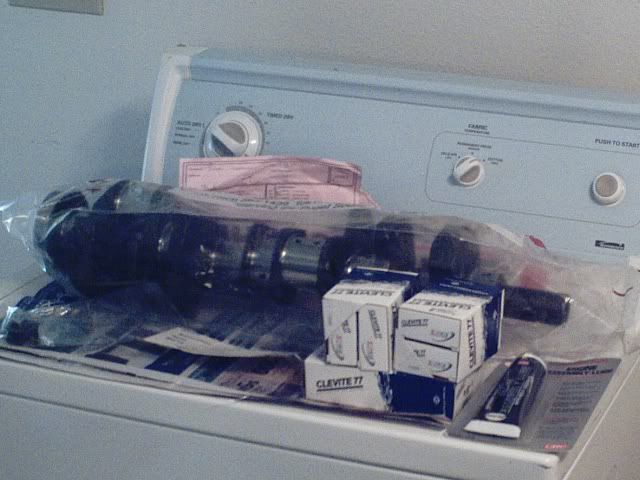

First, make sure that fresh crank is nice and clean. Scrub her with hot soapy goodness to get rid of the machineing debries. Take some galley brushes to all the oil passenges. Yes, I am a batchlor.

Make sure you get it rinsed, dried, and oiled as soon as possible... cause that flash rust is a *****.

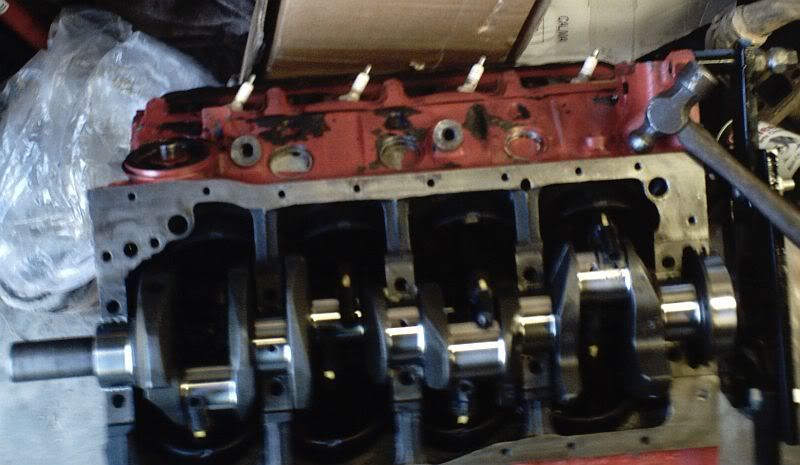

Mark the bearing caps so you don't mix them up.

The pic doesn't have the detail... but bearings aren't supposed to be copper colored with grooves.

uke:

After you remove the main and rod bearing caps.. the crank pretty much comes straight up out of there.

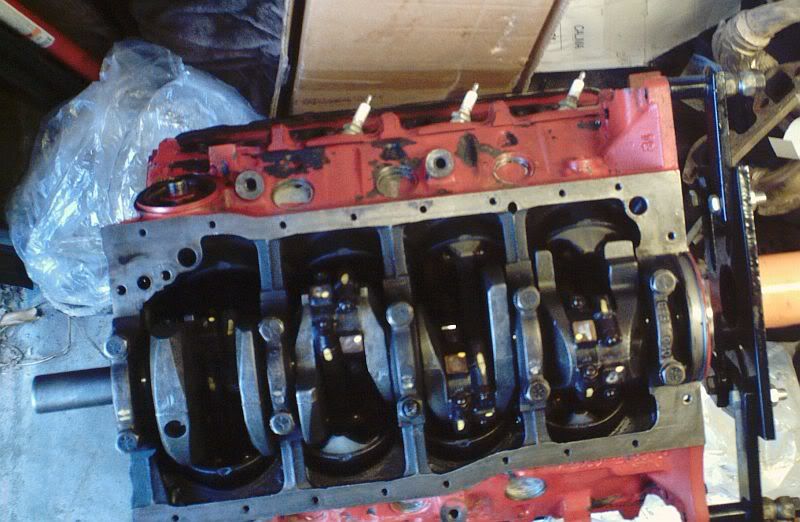

It takes a couple of people to put the new crank in. One to lower it in, one to guide and line up the rods onto the journals.

About an hour's more time, and you get all the clearances checked, and all the caps torqued.

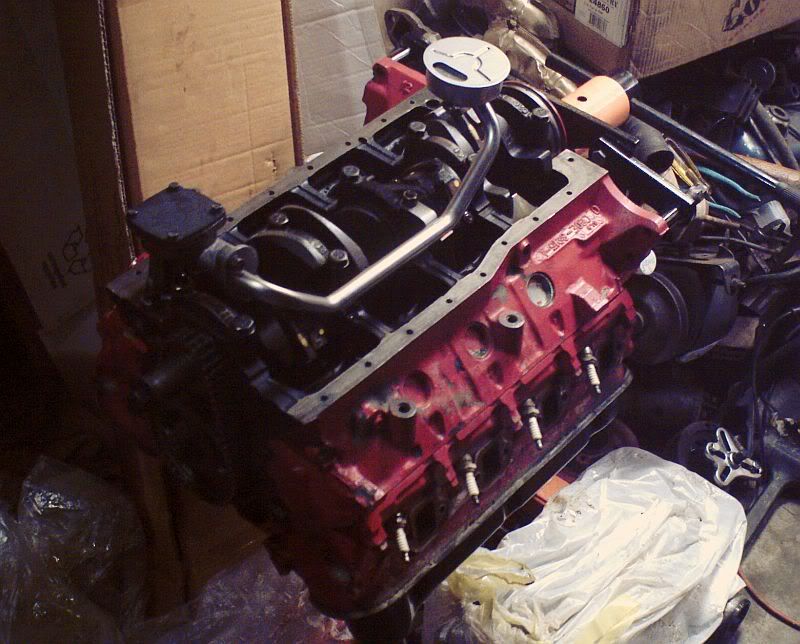

Some more time, and the bottom end is ready to be buttoned up.

Hopefully I will get it painted and the rest of the motor closed up and ready to drop in tomarrow.