P

If its free, its P

Hey fellars, I recently got into a project and started searching around for DIY trusses and brackets that lead me to Artec Industries. I searched like hell on PBB firstly and found very little real world feedback on thier products. I asked around a bit and called and spoke to Art as well and ended up ordering a few things. Here's a running thread on what I've recieved and am going to use...

http://www.midwestwheeler.com/index.php?topic=333.msg2634#new

Here's a quick "at first glance" copy paste as well. Hope it helps someone down the road.

Obviously this company does Aviation business. Best packaging I have seen since I was doing Aviation parts ! laughing Heres a pic,

I didnt even start unwrapping the truss because in that wrap job there are 4 bracket/tab sets for the upper and lower links at the axle as well as a 12 pack of gussets I ordered. Notice the attention to detail in that they even used cardboard tubes on the ends of the truss to protect not only the edges but primarily keep the 70lbs of steel from going through the box ( Im sure Im not the only one on here that has ordered steel piece parts and recieved a mangled ass mess of a cardboard box with pieces missing and or hanging out of the sum bee.) banghead

Ok so now that I have sucked off the shipping department at Artec, I'll go ahead and shoot props to Kelly (blacksheep10) who is the Artec Distributor I ordered the parts through. I feel like this was the best method for me to go on this project to accomplish both a clean install, but also keep the timeline of this build moving along ! So again... thank you Kelly/blacksheep/Vertical Limits for getting the quote to me quickly, my questions answered fast and the parts here as soon as Artec was able to make them available ! drinkinbuddies

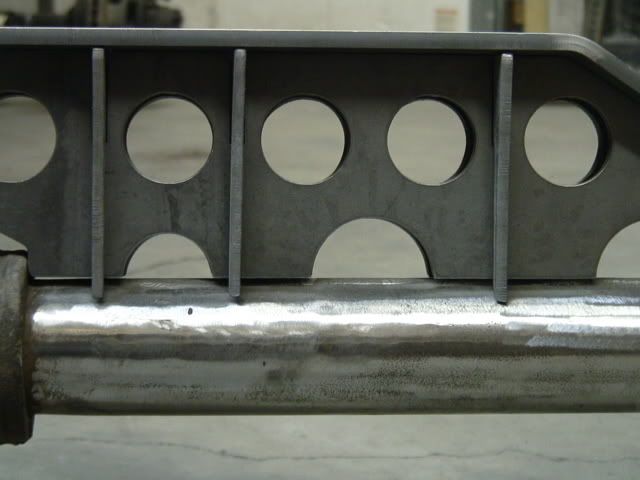

So moving right along. These are some engineered "dammit" pieces. Having ordered several times from Ballistic fab,, BTF etc dating back to when they first came on to the scene up to recently enough as the Chuggy build.. The technology of indexed tabs with small indents and holes is almost identical to Ball Fab and others, but the small attention to details like protection and accessiblity to zerks for regular maintenance on JJ's and other style joints really caught my eye. Hell, when I built my buggy I had both Johnny Joints and Ballistic 3.0s on it and NO ONE was building tabs designed to protect and function with this style of end ( rebuildable, durable, greasable... and basically superior to rodends IMO flipoffsmirk )

Here's a pic off Artec's site with details for those interested.

So on to what I got. If you refer to the first pic I posted you will see an intimidating pile of lazer perfect cut, CNC bent tabs and pieces that looks like a puzzle you'd never sort out. I set out preschooler style just sticking things together to see were they seemed to work and even not looking at the pictures of the multi-tabbed brackets off the Artec site it doesnt take alot of flipping and flopping pieces to sort out what goes were. I then pulled up the site and pffft, if your looking at the Artec pics on the site its nothing. My point = Simple stuff to work with.

Well for now thats all I got, its late and I worked a 13hr shift so Im going to relax and crash out. I'll continure tommorow with some mock up test fit pics and further detail on how well these pieces work real world on the TJ project you can find here.

http://www.midwestwheeler.com/index.php?topic=324.0

http://www.midwestwheeler.com/index.php?topic=333.msg2634#new

Here's a quick "at first glance" copy paste as well. Hope it helps someone down the road.

Obviously this company does Aviation business. Best packaging I have seen since I was doing Aviation parts ! laughing Heres a pic,

I didnt even start unwrapping the truss because in that wrap job there are 4 bracket/tab sets for the upper and lower links at the axle as well as a 12 pack of gussets I ordered. Notice the attention to detail in that they even used cardboard tubes on the ends of the truss to protect not only the edges but primarily keep the 70lbs of steel from going through the box ( Im sure Im not the only one on here that has ordered steel piece parts and recieved a mangled ass mess of a cardboard box with pieces missing and or hanging out of the sum bee.) banghead

Ok so now that I have sucked off the shipping department at Artec, I'll go ahead and shoot props to Kelly (blacksheep10) who is the Artec Distributor I ordered the parts through. I feel like this was the best method for me to go on this project to accomplish both a clean install, but also keep the timeline of this build moving along ! So again... thank you Kelly/blacksheep/Vertical Limits for getting the quote to me quickly, my questions answered fast and the parts here as soon as Artec was able to make them available ! drinkinbuddies

So moving right along. These are some engineered "dammit" pieces. Having ordered several times from Ballistic fab,, BTF etc dating back to when they first came on to the scene up to recently enough as the Chuggy build.. The technology of indexed tabs with small indents and holes is almost identical to Ball Fab and others, but the small attention to details like protection and accessiblity to zerks for regular maintenance on JJ's and other style joints really caught my eye. Hell, when I built my buggy I had both Johnny Joints and Ballistic 3.0s on it and NO ONE was building tabs designed to protect and function with this style of end ( rebuildable, durable, greasable... and basically superior to rodends IMO flipoffsmirk )

Here's a pic off Artec's site with details for those interested.

So on to what I got. If you refer to the first pic I posted you will see an intimidating pile of lazer perfect cut, CNC bent tabs and pieces that looks like a puzzle you'd never sort out. I set out preschooler style just sticking things together to see were they seemed to work and even not looking at the pictures of the multi-tabbed brackets off the Artec site it doesnt take alot of flipping and flopping pieces to sort out what goes were. I then pulled up the site and pffft, if your looking at the Artec pics on the site its nothing. My point = Simple stuff to work with.

Well for now thats all I got, its late and I worked a 13hr shift so Im going to relax and crash out. I'll continure tommorow with some mock up test fit pics and further detail on how well these pieces work real world on the TJ project you can find here.

http://www.midwestwheeler.com/index.php?topic=324.0

, there were chunks of of square box padding (almost weighed as much as the truss alone) in every inch of the truss as if were a piece of fine China shipping across the mountains,, and then the seran-wrap the whole thing! scrazy packing, but the box was in superior condition upon arrival.

, there were chunks of of square box padding (almost weighed as much as the truss alone) in every inch of the truss as if were a piece of fine China shipping across the mountains,, and then the seran-wrap the whole thing! scrazy packing, but the box was in superior condition upon arrival.