Ok, I finaly manageed to get back on this this weekend. Working 10hr days building things out of steel makes it hard to come home and do it for another 4, but hey, at least it's fun, right?

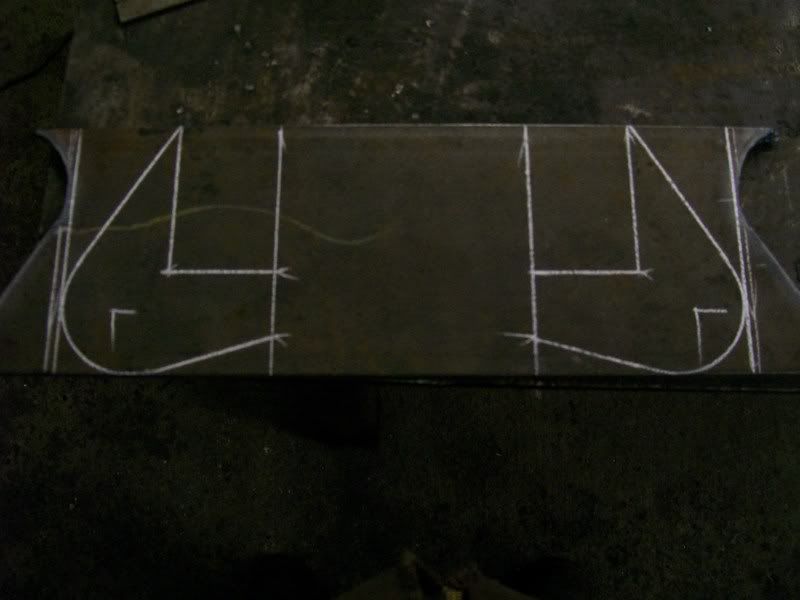

Finished a little cleaning of the frame and notched the front for the new spring hanger. I like to replace the front crosmember, it looks way cleaner than welding mounts under the old one and makes for a more sturdy place to mount a winch, etc...

Finished a little cleaning of the frame and notched the front for the new spring hanger. I like to replace the front crosmember, it looks way cleaner than welding mounts under the old one and makes for a more sturdy place to mount a winch, etc...