Cascade_Crawler

Well-Known Member

NotMatt said:That is pretty tall... heh.

Oh yeah, and the press is not absolutely required on the needle bearings. I remember I got discouraged at that point too, but I was able to pop both of those things off with a hammer and a properly sized piece of pipe if I remember right.

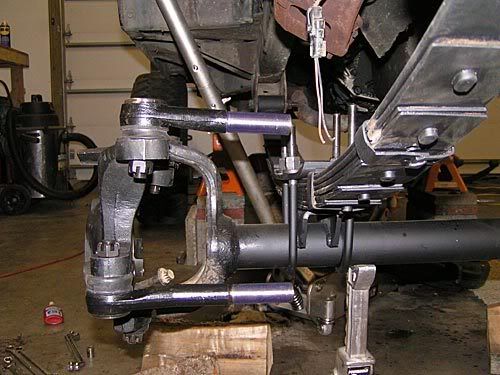

Got them out