dirtyhall

Well-Known Member

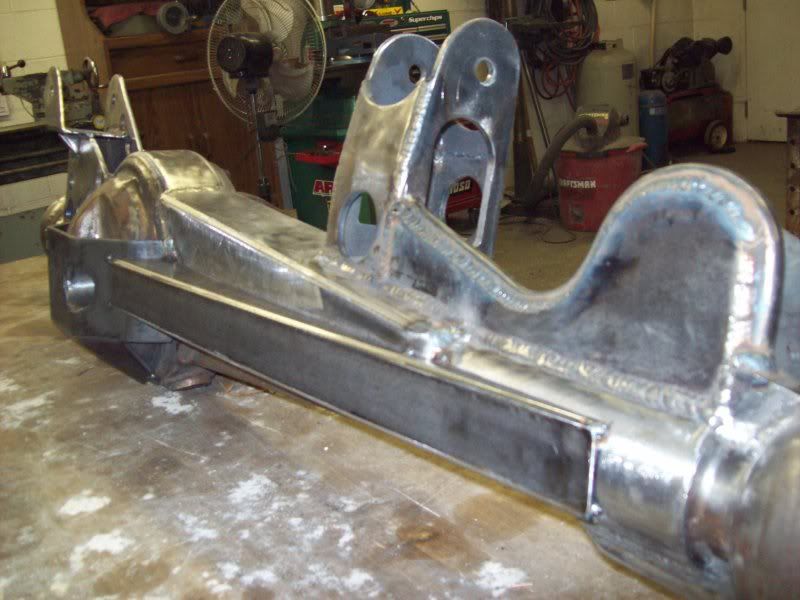

I see why you call this rig "The Mistress", tons of time and work going into it. Great work you are doing!!!

I see why you call this rig "The Mistress", tons of time and work going into it. Great work you are doing!!!

killer build .... itll be fun in the trails

All that work on custom hand built mounts, tabs and brackets and you toss a fawking generic TG diff guard on it? :flipoff:

If you want to do it I'll swing by next weekend and put the ifs setup together for ya.. If not I'll come by and heckle you anyway.. :redneck:

I think I gave away my last set but I bet I can find another set...

Looks sick