LIKES2CRAWL

Active Member

- Joined

- Aug 1, 2006

- Messages

- 41

Yooooo Mike, your in this video so is Dennis.

http://www.youtube.com/watch?v=QWn59LZliN8&feature=related

http://www.youtube.com/watch?v=QWn59LZliN8&feature=related

Yooooo Mike, your in this video so is Dennis.

http://www.youtube.com/watch?v=QWn59LZliN8&feature=related

righton, Odie was gettin it!

I didnt see my zuk in that vid.

Yea my bad, after watching it again I noticed it was Dennis's cruizer at the bottom of the hill at the 1:33 mark.

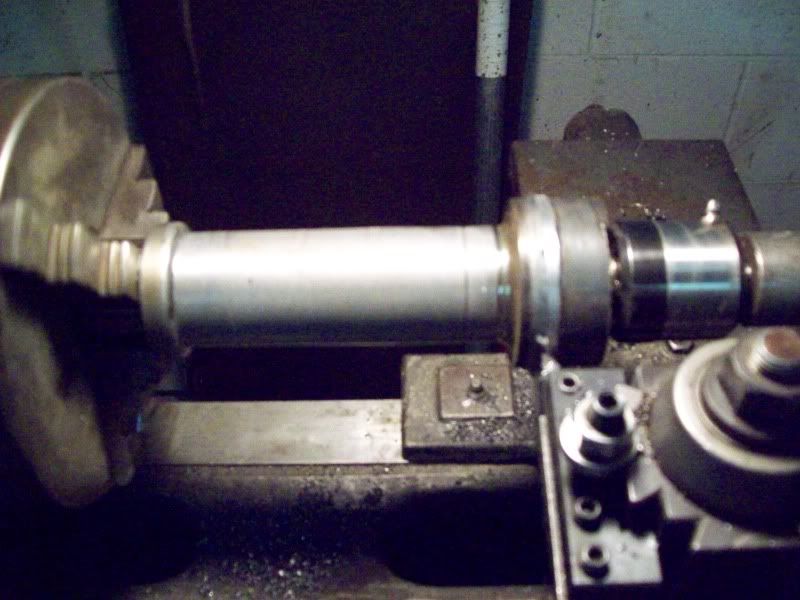

nice work

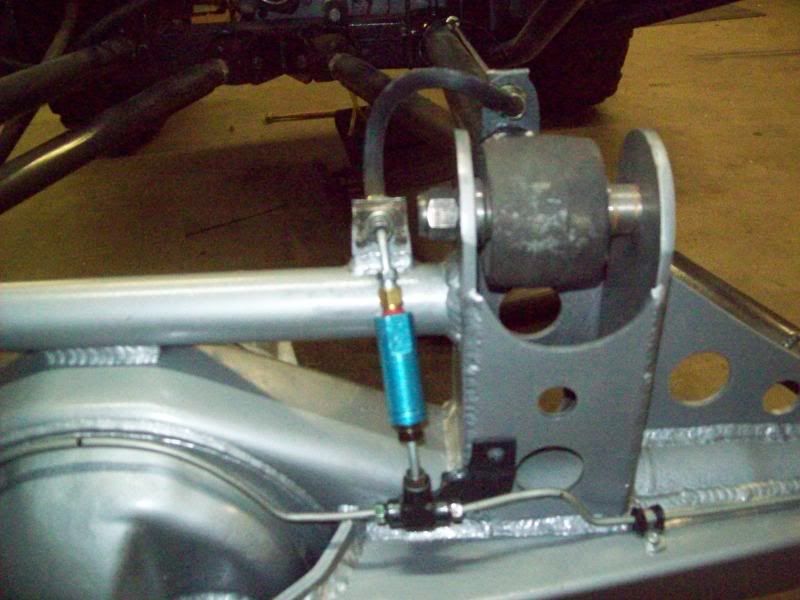

Looking good Mike! I think you may actually have the zuk done before my Bronco hits the trail again.

Looks like your going to be wheelin pretty soon! Where are you putting the cameras? Rock cams would be cool..:awesomework:

hay thats alpan in the white jee jeeeee jeee **** i cant say it .that dash is pritty *****en makes me want to git some vision x lights and come up behind you and blind you with my reflection. nice work mike.now quit makein little tab thingys and git it done.i want to go wheelin. as soon as i fix my junk.( that worked just fine before i tore it ap:flipoff:art)

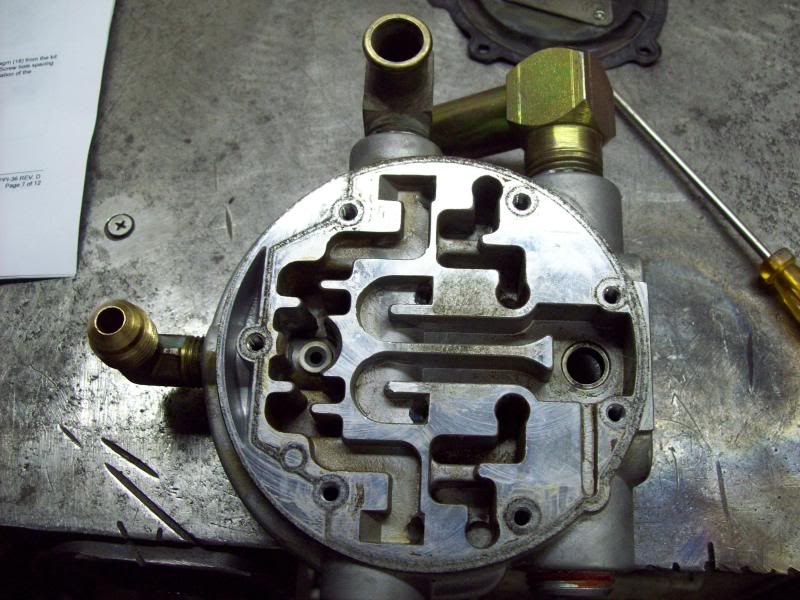

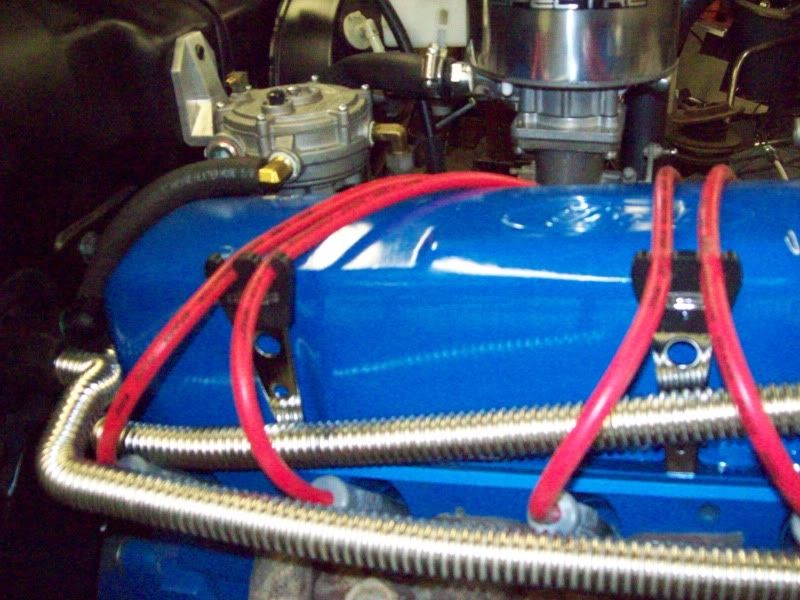

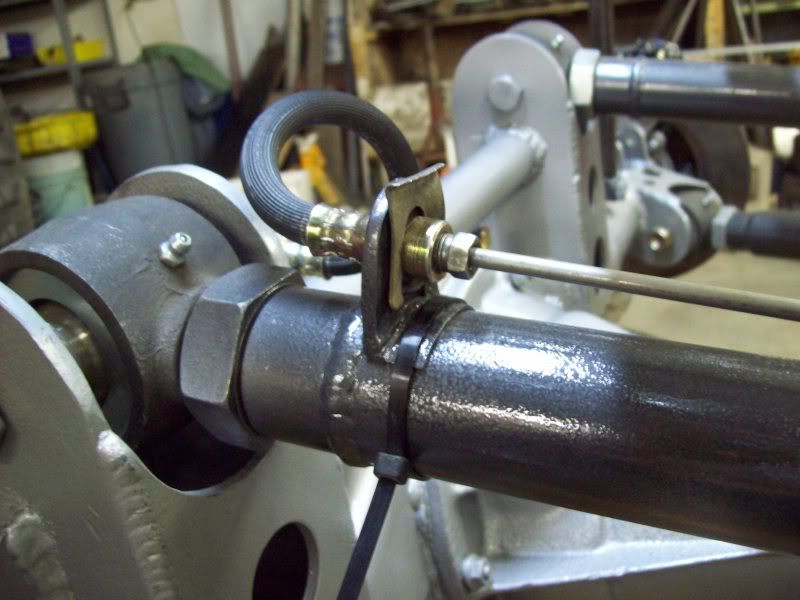

Also about the PS res, talking to everyone (PSC, Howe, POS) about my issues they all say that the suction and return ports should be right next to eachother. If I were you, I would cut that AN-6 return bung off and fill the hold then drill a new port on the lower edge near the bottom lip and weld in a AN-8 bung. Then all your return lines can be 1/2" which allows for better flow back to the res. This is what I learned.. just passing on some tech.

As far as I can see this is a flawless build... I love seeing updates. I am always learning from this thread. Thank you. :awesomework:

Thats great tech.Im really glad you said somthing because I ws looking at that last night starting to figure out what lines go where.I noticed the I.d. of the return line on the toy box is quite a bit bigger thasn the I.D. on the -6 return for the res. I was concidering boring it out and just hose clamping 1/2" return line to the res.

It probably would be best to just put a bigger i.d. fitting on the res though.The problem I cant weld alluminum.I have to go find peeps that can.

Thanks.:beer: