Pook

Well-Known Member

more crappy cell phone shots.

my cell phone doesn't like the shop lighting.

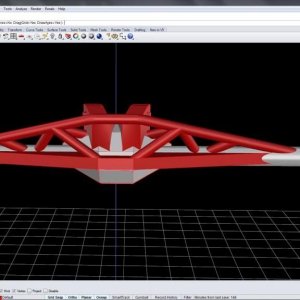

A few pics of the rear diff link/truss welded up. I've got more done than this but I'll wait till I can get some good photo's before I post it up.

my cell phone doesn't like the shop lighting.

A few pics of the rear diff link/truss welded up. I've got more done than this but I'll wait till I can get some good photo's before I post it up.