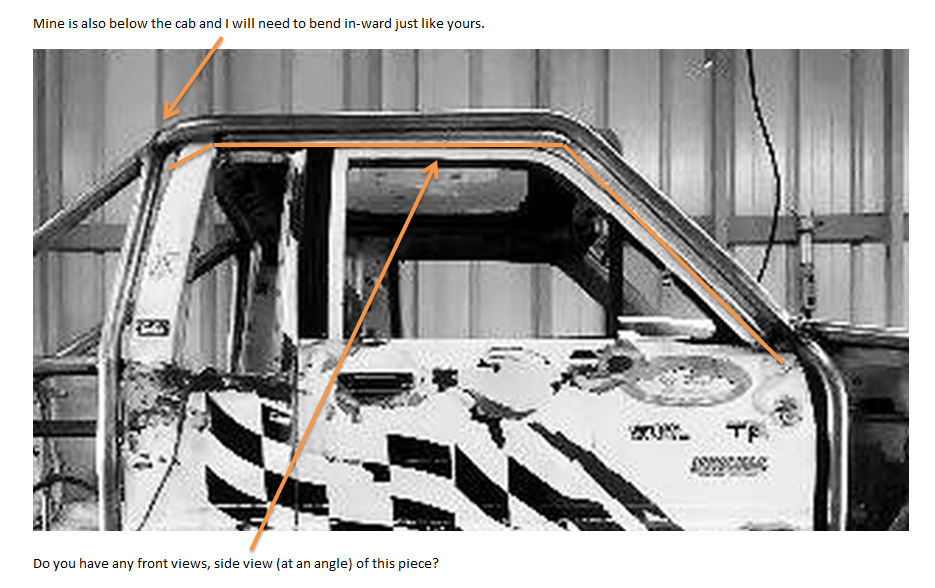

Your drawing looks good. Not a yota but I attached a couple pics of my buddy's s10 I am building a section at a time between rides so he doesn't have downtime. Figured another exo to look at might help. Sill have a good bit left on his. Some helpful comments posted already for you.

As for the front glass comments, it adds significant strength. I built his extremely tight to the body for looks and am sure the front glass will go before to many rolls. However I plan to cut it off and install oval mounting plates or removable tube splices when it does. Would have to do it anyway to install so might as well wait.

I can tell you if you wheel very hard the sides will get beat like a tin can without tube. I second protecting the jam. Would at least do something like chuck suggested.

As said make sure the hood opens. Place to watch is the one over the firewall. I made his hood open over the bar barely. Had to roll and bend it though.

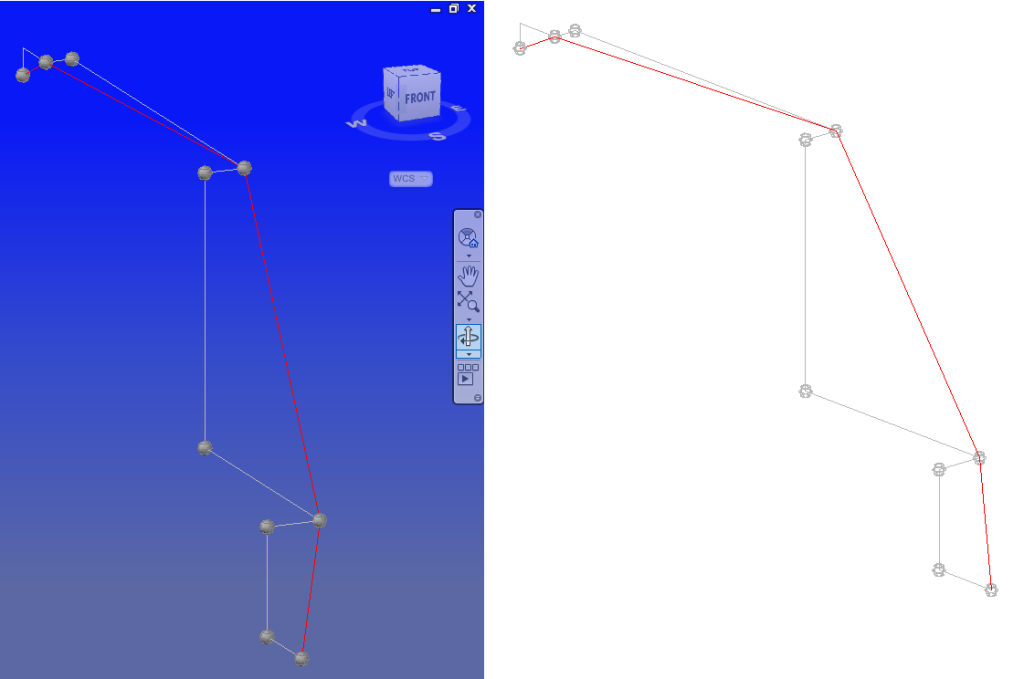

I have bend tech pro but prefer the ol floor tech method with homemade angle templates for his. I obsess a little over no splicing. Only time it is painfully difficult is when multiple bends are not in 90 degree plains. Bend tech would make those easier.

Had some time to kill so figured I would post in case something helps. Sure it will be nice since you seem to be going about it right.